machining operations pdf

Understanding Machining Operations An Overview

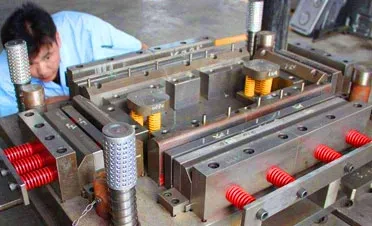

Machining operations are fundamental processes in manufacturing that involve the removal of material from a workpiece to achieve specified dimensions and surface finishes. These operations occur in various industries, including automotive, aerospace, and electronics, where precision and efficiency are critical. The purpose of this article is to provide an overview of machining operations, their types, and their significance in modern manufacturing.

Machining can be broadly categorized into two main types subtractive and non-subtractive manufacturing. Subtractive machining involves removing material through cutting tools, drills, or grinding wheels, while non-subtractive methods may include processes like electrochemical machining. This article will primarily focus on subtractive machining operations, as they are more commonly used in industrial applications.

Understanding Machining Operations An Overview

Another critical operation in the machining realm is milling. Milling machines can perform various tasks by rotating a cutting tool against a stationary workpiece. Unlike turning, where the workpiece moves, in milling, the tool is usually the moving component. Milling can produce complex shapes, slots, and holes, making it highly versatile. It can be categorized into two types conventional milling and climb milling, each offering different benefits in terms of surface finish and tool wear.

machining operations pdf

Drilling is yet another essential machining operation. It involves creating circular holes in a workpiece using a rotating drill bit. While drilling is often associated with producing holes, techniques such as reaming and tapping can further enhance hole accuracy and finish. Reaming enlarges existing holes while maintaining tight tolerances, and tapping creates internal threads for fastening applications.

Grinding is a precision machining operation used primarily for finishing. Unlike the earlier processes, grinding employs abrasives to remove material, resulting in high surface quality and tight tolerances. This operation is particularly important in the fabrication of high-precision components, such as gears and bearings. Types of grinding include surface grinding, cylindrical grinding, and centerless grinding, each serving distinct purposes within the manufacturing arena.

As industries evolve, so do machining techniques and technologies. Automation and computer numerical control (CNC) have significantly enhanced machining capabilities. CNC machines enable the automation of machining processes, providing greater precision, repeatability, and efficiency. Operators can input complex designs into the computer, and the CNC machine executes the machining operations automatically. This advancement has transformed traditional practices, allowing for the production of complex geometries that would be challenging or impossible with manual methods.

The importance of machining operations goes beyond producing individual parts; they play a crucial role in ensuring the overall efficiency and effectiveness of manufacturing systems. Effective machining contributes to reduced production times, lower material waste, and improved product quality. Furthermore, advancements in materials and cutting tool technologies continuously push the boundaries of machining capabilities, enabling manufacturers to tackle new challenges and meet evolving customer demands.

In conclusion, machining operations are vital components of modern manufacturing, encompassing various methods such as turning, milling, drilling, and grinding. Each operation has its unique advantages and applications, contributing to the successful fabrication of a diverse range of products. The rise of CNC technology has further propelled machining into a new era of efficiency and precision, making it an indispensable aspect of contemporary industrial practices. As technology advances, it will be exciting to see how machining continues to evolve and shape the future of manufacturing.

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Precision Engineering, Industrial EfficiencyNewsJul.13,2025

-

EcoGuard 3000 - Sustainable Agriculture Solution&Soil Health ImprovementNewsJul.13,2025

-

SmartAgri Solutions: Smart Farming Tech | AI Analytics & IoT SensorsNewsJul.13,2025

-

[Product Name]-[Company Name]|Business Efficiency&InnovationNewsJul.13,2025

-

Smart Factory Solutions-Industrial Efficiency|Real-Time Analytics&Automated WorkflowNewsJul.12,2025

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Durable, Reliable, CustomizedNewsJul.12,2025