high quality investment casting

High-Quality Investment Casting A Key to Precision Engineering

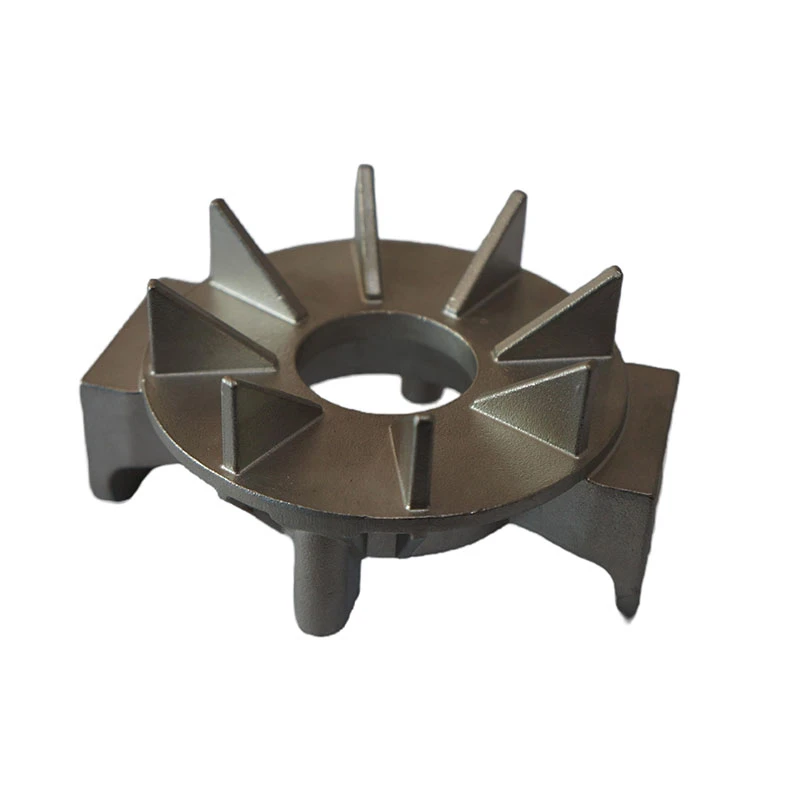

Investment casting, also known as lost-wax casting, is a sophisticated manufacturing process that has become essential in producing high-quality components across various industries. Renowned for its ability to achieve complex geometries with exceptional precision, investment casting offers significant advantages over traditional casting methods. With a focus on high-quality outcomes, this technique has gained popularity in sectors ranging from aerospace and automotive to medical and industrial equipment.

At the core of investment casting is its intricate methodology, which begins with creating a wax pattern that accurately reflects the final product's design. This wax pattern is coated with a ceramic shell, which is then heated to melt out the wax, leaving a precise mold. This process enables the production of near-net-shape components, reducing the need for extensive machining and minimizing material waste—an essential consideration in today’s environmentally-conscious manufacturing landscape.

High-Quality Investment Casting A Key to Precision Engineering

Material versatility is another advantage of investment casting. A wide range of materials, including stainless steel, aluminum, nickel-based alloys, and even specialty materials, can be utilized to manufacture components. This flexibility allows engineers and designers to select the most suitable material for their specific application, considering factors such as strength, weight, corrosion resistance, and thermal properties. Consequently, investment casting becomes a preferred choice when developing components for high-stress environments.

high quality investment casting

Within the realm of investment casting, the focus on quality control is paramount. Advanced inspection techniques, such as non-destructive testing (NDT), are often employed to ensure that components meet required specifications. These tests can identify flaws such as porosity, cracks, or inclusions that could compromise structural integrity. By implementing rigorous quality assurance measures, manufacturers enhance the reliability of their products and foster trust with their clients. This commitment to quality is critical in industries like aerospace and medical devices, where component failure can have catastrophic consequences.

The process of investment casting also promotes sustainability in manufacturing. The near-net-shape production minimizes material waste, and the ability to reuse ceramic shells further contributes to reducing the environmental impact. Additionally, with advancements in 3D printing technology, investment casting can leverage additive manufacturing to create more intricate patterns that would be challenging to produce through traditional methods. This integration of technologies not only enhances design capabilities but also streamlines production processes, leading to shorter lead times and cost savings.

As industries increasingly emphasize innovation and efficiency, high-quality investment casting remains an indispensable technique in modern manufacturing. Companies that adopt this process can produce superior components that align with the evolving demands of the market. Moreover, with the rise of smart manufacturing and digitalization, investment casting is poised to benefit from enhanced data analytics, process simulations, and automation, further refining its contribution to quality output.

In conclusion, high-quality investment casting is a vital component of precision engineering that facilitates the production of complex, reliable, and sustainable components. Its ability to meet rigorous quality standards and adapt to various materials makes it essential for applications in aerospace, medical, and beyond. As manufacturers continue to embrace advanced technologies and quality control measures, investment casting will undoubtedly play a pivotal role in shaping the future of high-performance manufacturing. The ongoing advancements in this field will not only enhance product quality but also contribute significantly to the sustainability goals of modern industry, making high-quality investment casting a cornerstone of innovative engineering solutions.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025