Fév . 14, 2025 06:44

Back to list

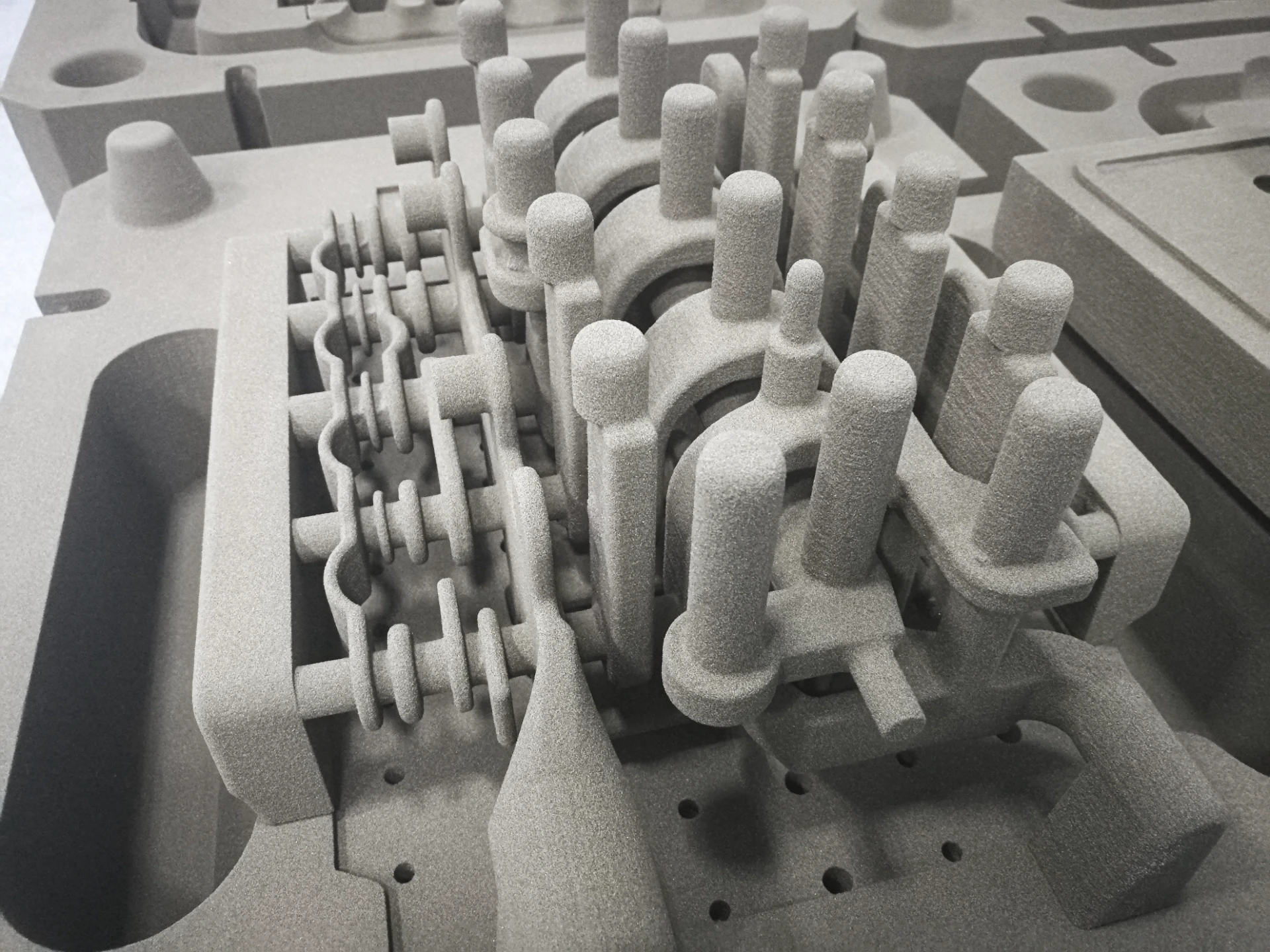

die cast dies

Die casting is a meticulous process involving the molding of molten metal into specific shapes using a die. The heart of this process is the die itself, a crucial component responsible for the accuracy, efficiency, and quality of the final product. In an industry where precision and consistency are paramount, understanding die cast dies becomes essential for both manufacturers and clients seeking top-tier die-casting solutions.

Authority in the die casting industry often comes from years of hands-on experience and a track record of successful projects. Companies renowned for their die casting services usually showcase an extensive portfolio, which illustrates their ability to handle diverse projects with varying complexity. These organizations often participate in industry conferences and publish research findings, contributing to the collective knowledge within the die casting community. Trustworthiness, on the other hand, is reflected in the transparency of communication between manufacturers and clients. It involves clear dialogues detailing the capabilities and limitations of die cast dies, ensuring realistic expectations. Trust is further built through commitment to quality assurances, where manufacturers provide guarantees on the performance of their dies, frequently backed by certifications or endorsements from reputable industry bodies. For those looking to source die casting services, selecting a provider with extensive experience, a strong reputation for expertise, authoritative industry presence, and a trustworthy client relationship is crucial. Such partners provide not only superior die cast dies but also invaluable insight into optimizing casting processes to meet specific production goals. Whether it involves creating lightweight components for vehicles or robust parts for industrial machinery, the right choice in die cast dies and providers can make a significant difference in product quality and project success.

Authority in the die casting industry often comes from years of hands-on experience and a track record of successful projects. Companies renowned for their die casting services usually showcase an extensive portfolio, which illustrates their ability to handle diverse projects with varying complexity. These organizations often participate in industry conferences and publish research findings, contributing to the collective knowledge within the die casting community. Trustworthiness, on the other hand, is reflected in the transparency of communication between manufacturers and clients. It involves clear dialogues detailing the capabilities and limitations of die cast dies, ensuring realistic expectations. Trust is further built through commitment to quality assurances, where manufacturers provide guarantees on the performance of their dies, frequently backed by certifications or endorsements from reputable industry bodies. For those looking to source die casting services, selecting a provider with extensive experience, a strong reputation for expertise, authoritative industry presence, and a trustworthy client relationship is crucial. Such partners provide not only superior die cast dies but also invaluable insight into optimizing casting processes to meet specific production goals. Whether it involves creating lightweight components for vehicles or robust parts for industrial machinery, the right choice in die cast dies and providers can make a significant difference in product quality and project success.

Prev:

Latest news

-

Precision Machining & Manufacturing | Aerospace ExpertsNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision, Quality, CustomizationNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun|Precision Customization&Reliable Fluid ControlNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Fluid Control, CustomizableNewsAug.05,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Customization, Quality AssuranceNewsAug.05,2025

PRODUCTS CATEGORIES