Fév . 18, 2025 08:08

Back to list

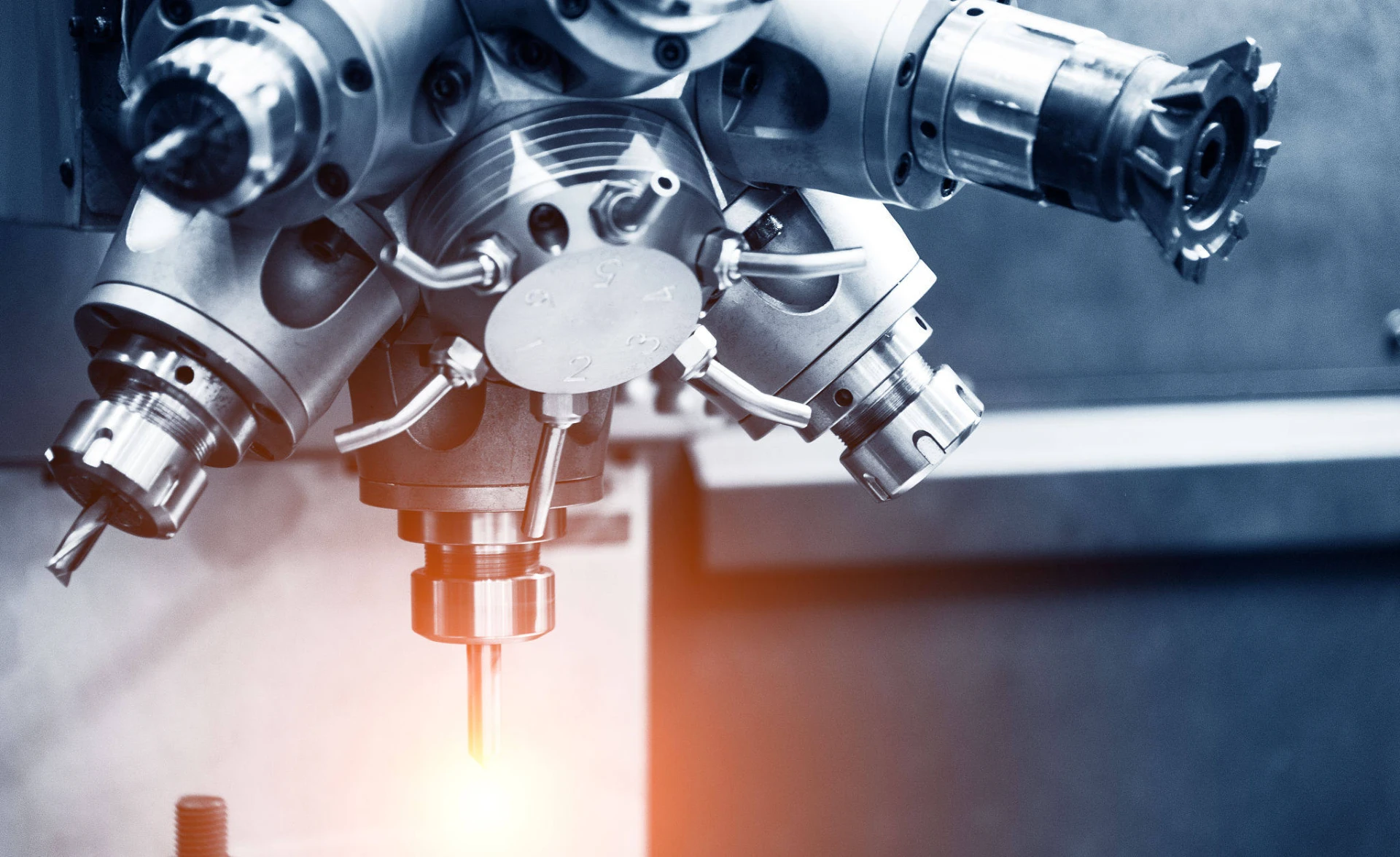

sheet metal stamping manufacturer

The world of automotive manufacturing is evolving at a breathtaking pace, and at the heart of this evolution is the ever-crucial process of sheet metal stamping. In an industry where precision, durability, and efficiency are paramount, automotive sheet metal stamping stands as a pillar of automotive production, embodying the intersection of advanced technology and meticulous craftsmanship.

Authoritativeness in automotive sheet metal stamping comes from a legacy of innovation and excellence. Leading manufacturers have spent decades honing their techniques, investing in research and development to push the boundaries of what is possible with metal stamping. This ongoing commitment to advancement ensures that they are not simply meeting industry standards but setting them. By pioneering new methodologies and investing in high-quality materials and machinery, these manufacturers establish themselves as authorities in the field, offering products that are synonymous with reliability and durability. Trustworthiness is an intrinsic quality in the automotive sheet metal stamping industry, as it directly affects vehicle safety and performance. Vehicle manufacturers and end consumers place their trust in these components, expecting them to perform under various conditions and over the vehicle's lifetime. This trust is built on a foundation of rigorous testing and quality assurance processes. Each component must undergo stringent testing for tensile strength, resistance to wear and tear, and overall durability. Only parts that meet or exceed these rigorous standards are integrated into the vehicles, ensuring safety and longevity. In conclusion, automotive sheet metal stamping is far more than a mere production process; it is a critical component of vehicle manufacturing that combines sophisticated technology with specialized expertise. Professionals in the field continue to innovate and adapt, ensuring that the components produced are of the highest quality, reinforcing the industry's reputation for reliability and excellence. By maintaining this focus on experience, expertise, authoritativeness, and trustworthiness, the automotive sheet metal stamping industry continues to drive the future of automotive manufacturing, one precisely stamped component at a time.

Authoritativeness in automotive sheet metal stamping comes from a legacy of innovation and excellence. Leading manufacturers have spent decades honing their techniques, investing in research and development to push the boundaries of what is possible with metal stamping. This ongoing commitment to advancement ensures that they are not simply meeting industry standards but setting them. By pioneering new methodologies and investing in high-quality materials and machinery, these manufacturers establish themselves as authorities in the field, offering products that are synonymous with reliability and durability. Trustworthiness is an intrinsic quality in the automotive sheet metal stamping industry, as it directly affects vehicle safety and performance. Vehicle manufacturers and end consumers place their trust in these components, expecting them to perform under various conditions and over the vehicle's lifetime. This trust is built on a foundation of rigorous testing and quality assurance processes. Each component must undergo stringent testing for tensile strength, resistance to wear and tear, and overall durability. Only parts that meet or exceed these rigorous standards are integrated into the vehicles, ensuring safety and longevity. In conclusion, automotive sheet metal stamping is far more than a mere production process; it is a critical component of vehicle manufacturing that combines sophisticated technology with specialized expertise. Professionals in the field continue to innovate and adapt, ensuring that the components produced are of the highest quality, reinforcing the industry's reputation for reliability and excellence. By maintaining this focus on experience, expertise, authoritativeness, and trustworthiness, the automotive sheet metal stamping industry continues to drive the future of automotive manufacturing, one precisely stamped component at a time.

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES