Technocrats Die Casting Solutions – Precision Hot & Cold Chamber Die Casting Experts

- Introduction: Defining technocrats die casting

in context - Technological Advancements in Die Casting Methods

- Comparing Hot Chamber and Cold Chamber Die Casting

- Precision in Die Casting Die Design

- Technical Advantages and Industry Data

- Customized Die Casting Solutions

- Technocrats Die Casting: Industry Placement and Conclusion

(technocrats die casting)

Understanding the Role of Technocrats Die Casting in Today’s Manufacturing

In the precision-driven arena of modern manufacturing, technocrats die casting has emerged as a critical process, enabling the mass production of complex metal components with high dimensional accuracy. This methodology utilizes advanced equipment and highly specialized expertise to fulfill the stringent requirements of sectors such as automotive, aerospace, electronics, and industrial machinery. The integration of automation, innovative die materials, and precise thermal controls has elevated die casting to unparalleled efficiency and repeatability standards. Consistent output, reduced lead times, and superior product integrity distinguish die casting technologies today. As industry demand for lighter, stronger, and intricately shaped components soars, understanding the current landscape and evolution of technocrats die casting becomes vital for businesses seeking a competitive edge.

Technological Advancements in Die Casting Methods

The sphere of die casting has witnessed a seismic shift in capabilities, largely credited to robust advancements in machinery automation, material science, and digital simulation. High-speed, closed-loop systems are now capable of processing over 400 shots per hour in optimized production environments. Modern die casting machines feature advanced servo-hydraulic drives and precision injection systems, reducing cycles and improving consistency across batches. In parallel, the utilization of latest die steel alloys and nano-coatings has extended mold life by over 30% compared to previous generations. Simulation-driven design, using powerful software suites, enables pre-production optimization, significantly reducing trial-and-error in die manufacturing and ensuring better metal flow, enhanced cooling, and diminished porosity. These enhancements champion reliability, energy efficiency, and safety, forging a new standard for global manufacturers.

Comparing Hot Chamber and Cold Chamber Die Casting

Selecting the appropriate die casting method is key for project success, with hot chamber and cold chamber processes each suited to particular alloys and applications. Hot chamber die casting integrates the injection mechanism directly with the molten metal reservoir, streamlining production for metals with low melting points such as zinc and magnesium. Conversely, cold chamber die casting keeps the injection system separate, enabling the use of higher melting point alloys such as aluminum and copper. The table below presents a comparative analysis of both methods based on crucial parameters.

| Parameter | Hot Chamber Die Casting | Cold Chamber Die Casting |

|---|---|---|

| Typical Alloys | Zinc, Magnesium | Aluminum, Copper |

| Cycle Time | 20–50 seconds | 40–120 seconds |

| Production Speed | High (up to 600 shots/hr) | Moderate (up to 200 shots/hr) |

| Die Wear | Lower | Higher |

| Component Complexity | Medium | High |

| Suitable for Automated Production | Yes | Yes (with some limitations) |

As reflected above, hot chamber die casting offers unrivaled speed for specific alloys, while cold chamber die casting stands out for versatility and the ability to handle more robust metals, albeit with relatively longer cycles and greater tooling demands. Manufacturers choose between the two based on chromatographic needs, material properties, and output volume requirements.

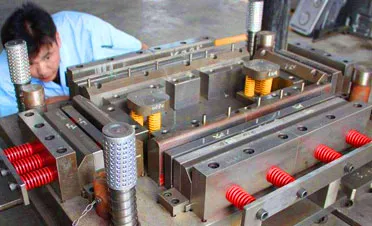

Precision in Die Casting Die Design

Critical to die casting success is the meticulous design of the die itself. Die casting die design directly influences product quality, operational efficiency, and tool longevity. Key decisions—ranging from gating and runner layout, cooling channel geometry, to venting and ejector systems—must be optimized from the outset. A robust die design minimizes turbulence, eliminates cold shuts, and ensures rapid, uniform cooling to prevent warpage and shrinkage. Computational fluid dynamics and finite element analyses allow engineers to anticipate internal defects before steel is cut, while digital twins and rapid prototyping enable iterative validation. Data-driven die modifications can reduce scrap rates by up to 65% according to recent industry studies. The right design strategy also simplifies post-processing requirements and extends the interval between maintenance cycles, lowering total cost of ownership. For high-volume producers, investing in best-in-class die design is a decisive factor in achieving sustainable success.

Technical Advantages and Industry Data

Unmatched dimensional precision is a standout advantage of contemporary die casting. Typical tolerances achieved are in the range of ±0.02 mm for small zinc components, compared to ±0.1 mm in legacy sand casting approaches. Surface finish readings, often reaching Ra 1.6 µm or better, eliminate the need for extensive machining post-casting. The energy utilization index for state-of-the-art die casting processes has dropped by 15–20% owing to improved process control and thermal management. Furthermore, full in-line X-ray and optical scanning now detect micro-defects in less than 5 seconds per part, driving first-pass yield rates above 97% in audited facilities. These capabilities, bolstered by modular automation and smart feedback systems, have enabled companies to scale up production without compromise on quality, meeting the rising global pressure for lightweight, durable metal assemblies.

Customized Die Casting Solutions

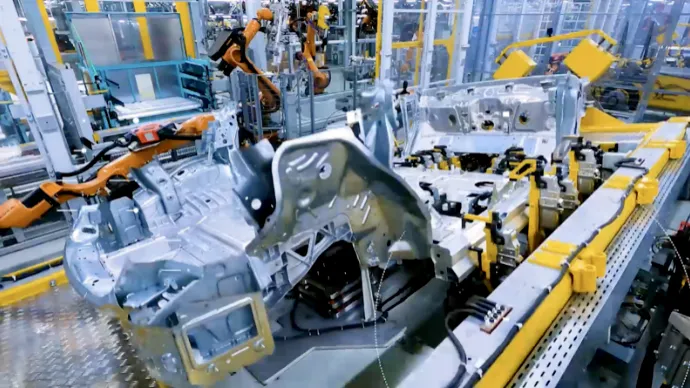

Diverse industry applications demand increasingly tailored solutions—standard die casting offerings no longer suffice for high-end customers. Many producers have responded with bespoke engineering services, combining advanced simulation, rapid tooling, and small-batch prototyping to accelerate customer product development. A typical custom die casting project involves detailed technical consultation, part geometry co-design, alloy selection aligned with functional goals (corrosion resistance, thermal conductivity, strength-to-weight ratio), and stringent test plans. Leading manufacturers provide end-to-end transparency via digital manufacturing dashboards and compliance documentation for various international standards. For instance, in the automotive sector, custom die casting supports the shift towards electric vehicle platforms with integrated battery cases and lightweight suspension mounts, delivering 20–40% weight reductions compared to machined alternatives. These unique, engineer-to-order approaches set the benchmark for responsiveness and innovation in the die casting domain.

The Position of Technocrats Die Casting in Modern Industry

As manufacturing priorities continue to shift towards higher efficiency and precision, technocrats die casting companies occupy a pivotal position within the industrial value chain. Through the continuous adoption of automation, data-centric design, and flexible customization, these firms deliver not only superior products but also transformative solutions adjusted to the evolving needs of sectors such as transportation, medical devices, and consumer goods. Industry leaders stand apart by their ability to deliver consistent quality at scale, leverage real-time monitoring, and implement sustainable practices that align with the stringent demands of global supply chains. In conclusion, the strategic selection of a die casting partner with a proven record—one that brings together expertise in hot chamber die casting and cold chamber die casting, an uncompromising focus on die casting die design, and the ability to offer fully customized product solutions—remains one of the most consequential decisions for manufacturers seeking durable, high-precision components in the twenty-first century.

(technocrats die casting)

FAQS on technocrats die casting

Q: What services does Technocrats Die Casting offer?

A: Technocrats Die Casting specializes in both hot chamber die casting and cold chamber die casting. They also provide expert die casting die design services. Their solutions cater to a variety of industrial applications.

Q: What is the difference between hot chamber and cold chamber die casting?

A: Hot chamber die casting is suitable for low-melting-point metals like zinc, while cold chamber is used for higher-melting-point metals like aluminum. Technocrats Die Casting is experienced in both methods. Choosing the right process depends on the material and product requirements.

Q: Why is die casting die design important?

A: Proper die casting die design ensures the quality and precision of the final components. Technocrats Die Casting uses advanced design techniques to improve efficiency and product performance. Good design reduces defects and production costs.

Q: Does Technocrats Die Casting handle custom die casting projects?

A: Yes, Technocrats Die Casting can manage custom projects tailored to specific client needs. They provide individualized hot chamber, cold chamber, and die design solutions. Customization ensures you get parts that fit your requirements exactly.

Q: What industries benefit from Technocrats Die Casting services?

A: Technocrats Die Casting serves industries such as automotive, electronics, and consumer goods. Their expertise covers a wide range of materials and applications. Reliable die casting die design makes them suitable for many manufacturing sectors.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.09,2025

-

Genuine OEM Lamps: Projector, LED, & Light Bulbs for All NeedsNewsAug.09,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.09,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Fluid ControlNewsAug.09,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Engineering, Customizable SolutionsNewsAug.08,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Fluid Control & Custom CastingNewsAug.08,2025