فوریه . 20, 2025 11:06

Back to list

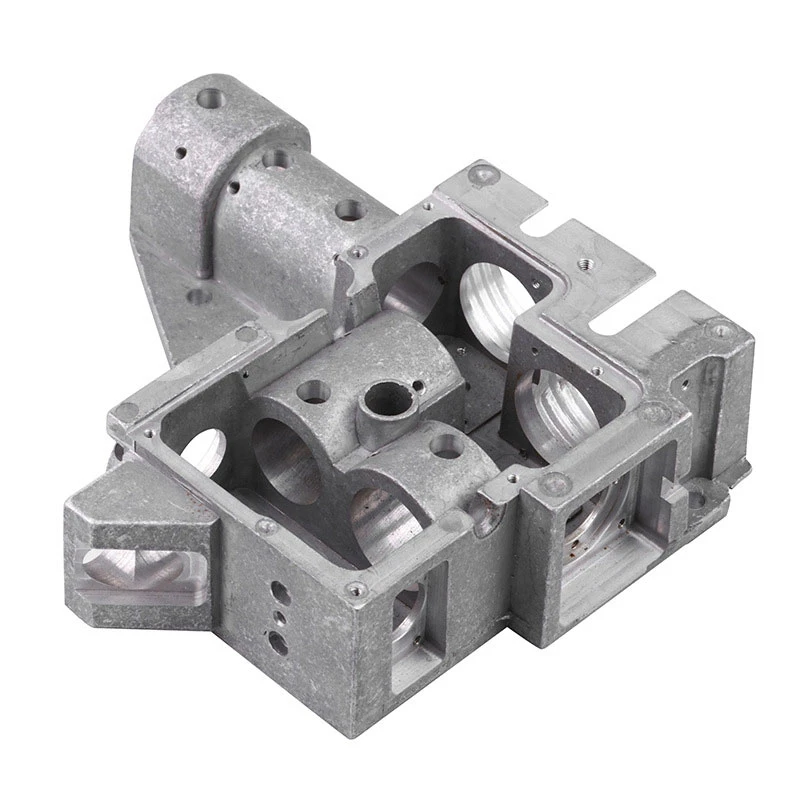

Oem Precision Castings Bearing

Stamped aluminum parts have steadily become a cornerstone in various industrial applications, owing to their remarkable balance of strength, lightweight properties, and cost-effectiveness. As industries worldwide lean toward more sustainable and efficient manufacturing solutions, these components offer compelling advantages that merit exploration.

Moreover, stamped aluminum components are easily customizable, another aspect that underscores their versatility and appeal. Whether it’s creating intricate designs for consumer electronics or robust components for heavy machinery, the malleability of aluminum allows engineers to push boundaries in design and functionality. This flexibility supports innovation, enabling businesses to refine and diversify their product offerings, thereby meeting the ever-evolving needs of the market. When it comes to authoritativeness, the role of verified certifications and compliance with international standards cannot be overlooked. Reputable manufacturers of stamped aluminum parts adhere to industry standards such as ISO 9001 for quality management, ensuring that each production phase is meticulously monitored and controlled. This adherence not only fosters confidence in the parts’ quality and reliability but also aligns with global best practices, positioning businesses as leaders in their field. Trustworthiness in stamped aluminum part production is further cemented by long-term partnerships with suppliers known for their stringent quality-assurance processes. Partnering with suppliers who prioritize transparency and sustainability in their operations reassures downstream industries of the consistency and environmental stewardship behind the products they employ. A supply chain characterized by integrity and reliability strengthens overall confidence in the end application, whether in high-stakes sectors like aeronautics or everyday consumer goods. In conclusion, stamped aluminum parts present a unique opportunity for industries aiming to balance cost efficiency, performance reliability, and eco-consciousness. Incorporating these components into production lines not only reduces environmental impact but also aligns with a global shift towards more sustainable manufacturing practices. By leveraging the depth of experience, expertise, authority, and trust that stamped aluminum parts embody, businesses can not only meet current industrial challenges but also set a precedent in quality and innovation for future endeavors. Through continued advancements in technology and design, these components hold the potential to revolutionize how we approach manufacturing, paving the way for a more sustainable and economically viable industrial landscape.

Moreover, stamped aluminum components are easily customizable, another aspect that underscores their versatility and appeal. Whether it’s creating intricate designs for consumer electronics or robust components for heavy machinery, the malleability of aluminum allows engineers to push boundaries in design and functionality. This flexibility supports innovation, enabling businesses to refine and diversify their product offerings, thereby meeting the ever-evolving needs of the market. When it comes to authoritativeness, the role of verified certifications and compliance with international standards cannot be overlooked. Reputable manufacturers of stamped aluminum parts adhere to industry standards such as ISO 9001 for quality management, ensuring that each production phase is meticulously monitored and controlled. This adherence not only fosters confidence in the parts’ quality and reliability but also aligns with global best practices, positioning businesses as leaders in their field. Trustworthiness in stamped aluminum part production is further cemented by long-term partnerships with suppliers known for their stringent quality-assurance processes. Partnering with suppliers who prioritize transparency and sustainability in their operations reassures downstream industries of the consistency and environmental stewardship behind the products they employ. A supply chain characterized by integrity and reliability strengthens overall confidence in the end application, whether in high-stakes sectors like aeronautics or everyday consumer goods. In conclusion, stamped aluminum parts present a unique opportunity for industries aiming to balance cost efficiency, performance reliability, and eco-consciousness. Incorporating these components into production lines not only reduces environmental impact but also aligns with a global shift towards more sustainable manufacturing practices. By leveraging the depth of experience, expertise, authority, and trust that stamped aluminum parts embody, businesses can not only meet current industrial challenges but also set a precedent in quality and innovation for future endeavors. Through continued advancements in technology and design, these components hold the potential to revolutionize how we approach manufacturing, paving the way for a more sustainable and economically viable industrial landscape.

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES