sand casting die

Understanding Sand Casting Die The Art and Science Behind a Timeless Manufacturing Process

Sand casting is one of the oldest and most versatile manufacturing processes, widely used in the production of metal parts and components. At the core of this intricate practice lies the sand casting die—a crucial element that shapes the final product. This article will delve into the essentials of sand casting die, exploring its design, material considerations, and its significance in various industries.

What is Sand Casting?

Before we dive into the intricacies of sand casting dies, it is essential to understand the sand casting process itself. Sand casting, also known as sand mould casting, involves creating a mold from a mixture of sand, clay, and water. This mold can accommodate molten metal poured into it, which subsequently solidifies into the desired shape once cooled. The flexibility of sand casting allows for the production of intricate designs and large components, making it a favored method across automotive, aerospace, and heavy machinery sectors.

Design and Function of Sand Casting Dies

Sand casting dies, often referred to as patterns, serve as the blueprint for the mold. These dies are designed to shape the negative image of the intended final product. The design process is a combination of artistic vision and engineering precision, ensuring that the final casting will meet operational specifications and tolerances.

To create the die, engineers start with a detailed 3D model of the final product. They consider various factors, including the ease of mold release, potential shrinkage of the material, and cooling times. A well-designed die accommodates these factors, minimizing defects such as warping, voids, or misalignment in the final casting.

Materials for Sand Casting Dies

The choice of material for sand casting dies is critical. Traditionally, wood was the material of choice due to its availability and workability. However, modern practices have seen a shift towards metals, plastics, and composites that can withstand higher temperatures and offer greater durability.

sand casting die

Metals such as aluminum and steel are commonly used because they provide enhanced strength and heat resistance. Additionally, these materials can be machined with high precision, allowing for the creation of complex shapes and designs. On the other hand, plastics and composites are gaining traction for producing lighter and more cost-effective patterns, especially in prototyping where lower production volumes are required.

Advantages and Disadvantages of Sand Casting Dies

The use of sand casting dies comes with its advantages. One of the primary benefits is the ability to create large parts, which is often challenging with other manufacturing methods. Moreover, the flexibility in design allows for the production of intricate geometries at a relatively low cost.

However, there are also challenges associated with sand casting dies. The initial setup and design phase can be time-consuming and costly, particularly for intricate patterns. Additionally, achieving a high level of surface finish and accuracy can be more challenging compared to other processes like die casting or injection molding.

Applications in Various Industries

The versatility of sand casting and its dies enables their use in various industries. In the automotive sector, sand casting is used for producing engine blocks, cylinder heads, and other critical components. The aerospace industry utilizes sand casting for components that demand intricate designs and reduced weight without sacrificing strength. Moreover, heavy machinery manufacturers rely on sand casting for producing parts that can withstand significant stress and wear.

Conclusion

In conclusion, sand casting die is an integral component of the sand casting process that combines art and science. Its design plays a vital role in determining the quality and functionality of the final product. As industries continue to evolve and demand more complex and customized designs, the significance of sand casting and the innovation surrounding casting dies will undoubtedly grow, ensuring that this age-old method remains relevant in modern manufacturing.

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

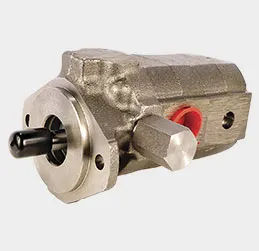

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025