مارس . 05, 2025 01:39

Back to list

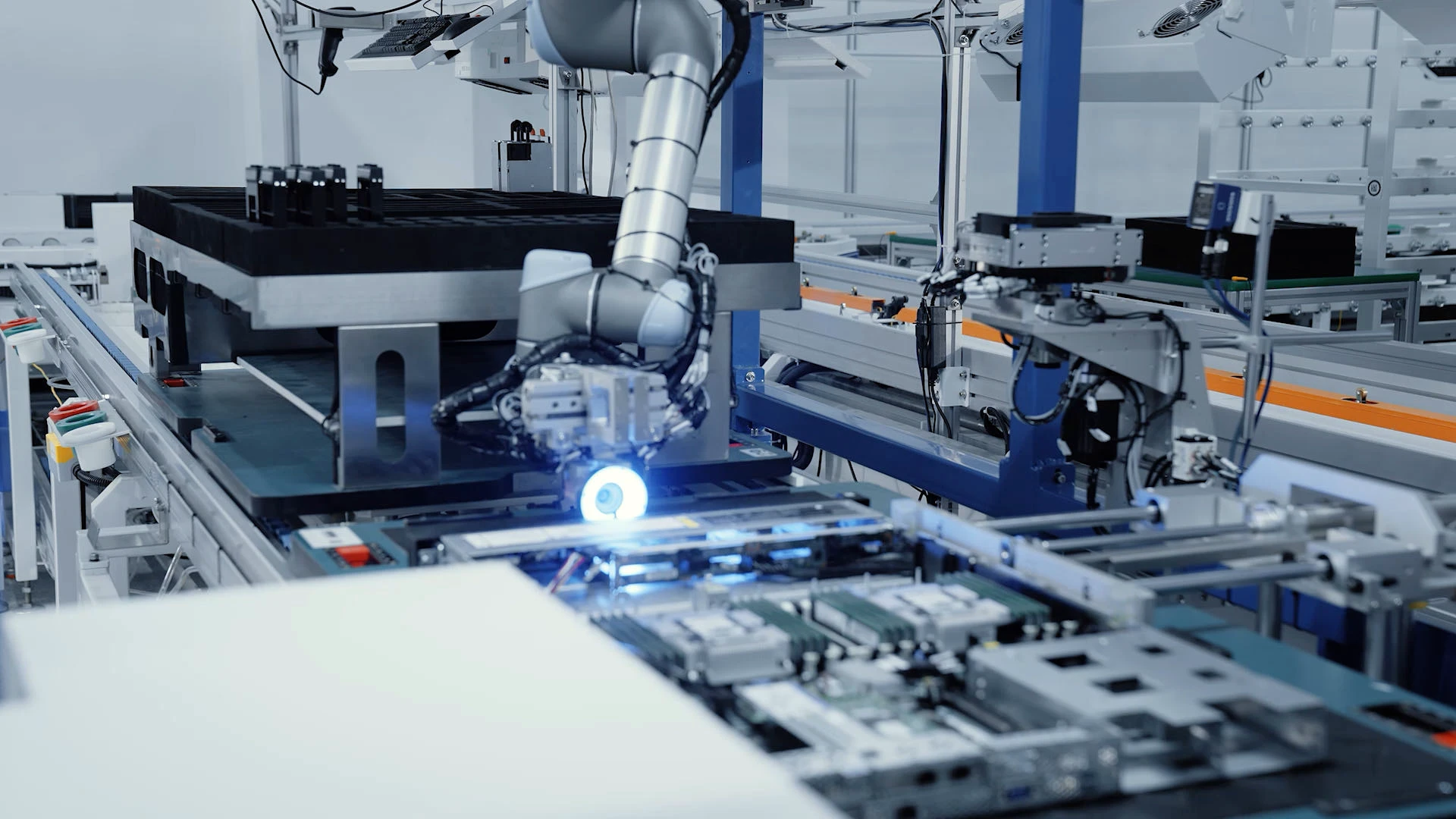

precision stamping part

In the realm of manufacturing, precision stamping parts stand as a testament to engineering prowess and meticulous craftsmanship. The journey from raw metal to finely crafted components is nothing short of impressive, embodying a seamless blend of technology and skill. The significance of these components spans various industries, from automotive to electronics, proving their indispensability in modern industrial applications.

Trustworthiness is further amplified through transparent communication and customer-centric services. Manufacturers often work closely with their clients during the design phase, offering bespoke solutions tailored to specific needs. This collaborative approach fosters long-term partnerships, as customers know they can rely on manufacturers to deliver products that meet and exceed expectations. The environmental sustainability of precision stamping is another aspect that enhances its appeal. The process is inherently efficient, as it maximizes the use of materials and generates minimal waste. Furthermore, ongoing advancements in stamping technology continue to reduce energy consumption and promote eco-friendly practices, aligning with the broader industry's shift toward sustainable manufacturing solutions. Real-world application of precision stamping is exemplified across various sectors. In the automotive industry, these parts are critical components in engines and transmissions, where their precision and durability directly impact vehicle performance and safety. Electronics manufacturers utilize precision-stamped components in the assembly of gadgets and devices, where reliability and miniaturization are of utmost importance. The medical field, too, benefits from precision stamping, where intricate parts are required for surgical instruments and diagnostic equipment. In conclusion, precision stamping parts are a cornerstone of the modern manufacturing landscape. Their creation embodies the pinnacle of engineering expertise, technological advancement, and uncompromising quality assurance. As industries evolve and demand ever-more sophisticated components, the role of precision stamping will undeniably continue to grow, cementing its status as an indispensable aspect of industrial production. Embracing these components not only elevates the functional quality of products but also reinforces the commitment to sustainable, reliable, and cutting-edge manufacturing practices.

Trustworthiness is further amplified through transparent communication and customer-centric services. Manufacturers often work closely with their clients during the design phase, offering bespoke solutions tailored to specific needs. This collaborative approach fosters long-term partnerships, as customers know they can rely on manufacturers to deliver products that meet and exceed expectations. The environmental sustainability of precision stamping is another aspect that enhances its appeal. The process is inherently efficient, as it maximizes the use of materials and generates minimal waste. Furthermore, ongoing advancements in stamping technology continue to reduce energy consumption and promote eco-friendly practices, aligning with the broader industry's shift toward sustainable manufacturing solutions. Real-world application of precision stamping is exemplified across various sectors. In the automotive industry, these parts are critical components in engines and transmissions, where their precision and durability directly impact vehicle performance and safety. Electronics manufacturers utilize precision-stamped components in the assembly of gadgets and devices, where reliability and miniaturization are of utmost importance. The medical field, too, benefits from precision stamping, where intricate parts are required for surgical instruments and diagnostic equipment. In conclusion, precision stamping parts are a cornerstone of the modern manufacturing landscape. Their creation embodies the pinnacle of engineering expertise, technological advancement, and uncompromising quality assurance. As industries evolve and demand ever-more sophisticated components, the role of precision stamping will undeniably continue to grow, cementing its status as an indispensable aspect of industrial production. Embracing these components not only elevates the functional quality of products but also reinforces the commitment to sustainable, reliable, and cutting-edge manufacturing practices.

Next:

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES