مارس . 05, 2025 01:02

Back to list

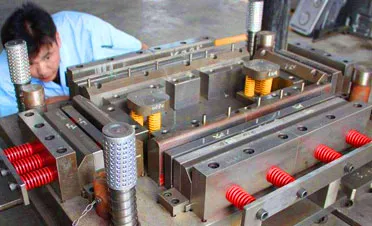

precision sheet metal stamping parts

Precision sheet metal stamping parts are integral components in modern manufacturing, utilized across a multitude of industries such as automotive, aerospace, electronics, and healthcare. Understanding the nuances of these components not only requires technical expertise but also invokes an appreciation for the precision and reliability they deliver in various applications.

Trustworthiness in precision sheet metal stamping is built over time, evidenced by long-standing partnerships with major industry players and an unyielding focus on meeting, if not exceeding, client expectations. Reliable manufacturers offer transparent processes, from initial consultations to after-sales support, fostering client confidence. Moreover, they ensure that all parts comply with industry regulations, offering peace of mind regarding product safety and performance. In terms of application, the versatility of precision sheet metal stamping parts is remarkable. In the automotive industry, they are essential for producing components such as brackets, clips, and engine parts, contributing to both the vehicle's structural integrity and aesthetic appeal. Aerospace manufacturers rely on precision-stamped parts for their lightweight yet robust properties, critical for aircraft efficiency and safety. In electronics, these parts form the backbone of many devices, providing structure and support for intricate circuit assemblies. The healthcare sector benefits from precision stamping through components used in medical devices, where accuracy and dependability are literally a matter of life and death. For businesses looking to integrate precision sheet metal stamping into their operations, selecting the right manufacturing partner is crucial. Key considerations include assessing the manufacturer's track record, their investment in technology, and their ability to deliver consistent quality at competitive rates. Furthermore, potential partners should be evaluated on their flexibility in terms of customization and responsiveness to design modifications, which can be pivotal in dynamic industries where product iterations occur frequently. In conclusion, precision sheet metal stamping represents a cornerstone of modern manufacturing, offering unmatched precision, efficiency, and reliability. By leveraging expert knowledge, authoritative processes, and trustworthy practices, manufacturers provide essential components that drive innovation across various sectors. For those in need of high-quality stamped parts, engaging with reputable manufacturers ensures not only superior products but also a collaborative partnership dedicated to continuous improvement and excellence in every project.

Trustworthiness in precision sheet metal stamping is built over time, evidenced by long-standing partnerships with major industry players and an unyielding focus on meeting, if not exceeding, client expectations. Reliable manufacturers offer transparent processes, from initial consultations to after-sales support, fostering client confidence. Moreover, they ensure that all parts comply with industry regulations, offering peace of mind regarding product safety and performance. In terms of application, the versatility of precision sheet metal stamping parts is remarkable. In the automotive industry, they are essential for producing components such as brackets, clips, and engine parts, contributing to both the vehicle's structural integrity and aesthetic appeal. Aerospace manufacturers rely on precision-stamped parts for their lightweight yet robust properties, critical for aircraft efficiency and safety. In electronics, these parts form the backbone of many devices, providing structure and support for intricate circuit assemblies. The healthcare sector benefits from precision stamping through components used in medical devices, where accuracy and dependability are literally a matter of life and death. For businesses looking to integrate precision sheet metal stamping into their operations, selecting the right manufacturing partner is crucial. Key considerations include assessing the manufacturer's track record, their investment in technology, and their ability to deliver consistent quality at competitive rates. Furthermore, potential partners should be evaluated on their flexibility in terms of customization and responsiveness to design modifications, which can be pivotal in dynamic industries where product iterations occur frequently. In conclusion, precision sheet metal stamping represents a cornerstone of modern manufacturing, offering unmatched precision, efficiency, and reliability. By leveraging expert knowledge, authoritative processes, and trustworthy practices, manufacturers provide essential components that drive innovation across various sectors. For those in need of high-quality stamped parts, engaging with reputable manufacturers ensures not only superior products but also a collaborative partnership dedicated to continuous improvement and excellence in every project.

Prev:

Next:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES