Exploring the Benefits of Plaster of Paris in Sand Casting Techniques

Plaster of Paris Sand Casting An Overview

Plaster of Paris and sand casting are two traditional methods used in metalworking and sculpting, providing artists and manufacturers with versatile techniques for creating intricate designs and parts. While both methods are distinct, they can also be effectively combined to leverage the benefits of each. This article explores the process, advantages, and applications of plaster of Paris sand casting, shedding light on why it remains a popular choice in various industries.

Understanding the Basics

Plaster of Paris, a quick-setting material made from gypsum, is widely recognized for its ability to create detailed molds and casts. When mixed with water, it forms a thick paste that can be shaped and molded before it hardens into a rigid form. The term plaster of Paris originates from the large quantities of gypsum found near Paris, which were used in this versatile material.

Sand casting, on the other hand, is a well-established metal casting process where molten metal is poured into a mold formed from sand. The sand combines with a binding agent, usually clay, to create a mold that can withstand the heat of molten metal. The advantage of this process lies in its ability to produce intricate shapes and sizable objects with relative ease.

The Combination of Plaster of Paris and Sand Casting

Combining plaster of Paris with traditional sand casting enhances both methods, providing unique benefits that cater to various creative and industrial needs. In this hybrid technique, plaster is used to create a precise mold that is then employed in the sand casting process. The plaster mold captures the fine details, which are especially desirable in sculptural applications, while the sand provides the strength and heat resistance required for molten metal casting.

The Process

1. Mold Creation The initial stage involves creating a detailed sculpture or model of the desired finished piece. This model is then encased in a mixture of plaster of Paris to create a mold. The plaster is poured over the model and allowed to set, capturing all the fine details.

2. Sand Preparation Once the plaster has hardened, it can be used to create the sand mold. A mixture of sand and a binding agent is prepared and packed around the plaster mold. This step is crucial because it allows for accurate shaping capable of withstanding the metal's heat.

3. Metal Pouring After the sand mold is formed, it is time to pour the molten metal. The sand mold is filled with the chosen metal, which can be aluminum, bronze, or other suitable materials, depending on the project's requirements.

4. Cooling and Demolding After allowing sufficient time for the molten metal to cool, the sand mold is removed, revealing the final cast piece. The plaster mold can often be cleaned and reused for subsequent castings, enhancing its efficiency.

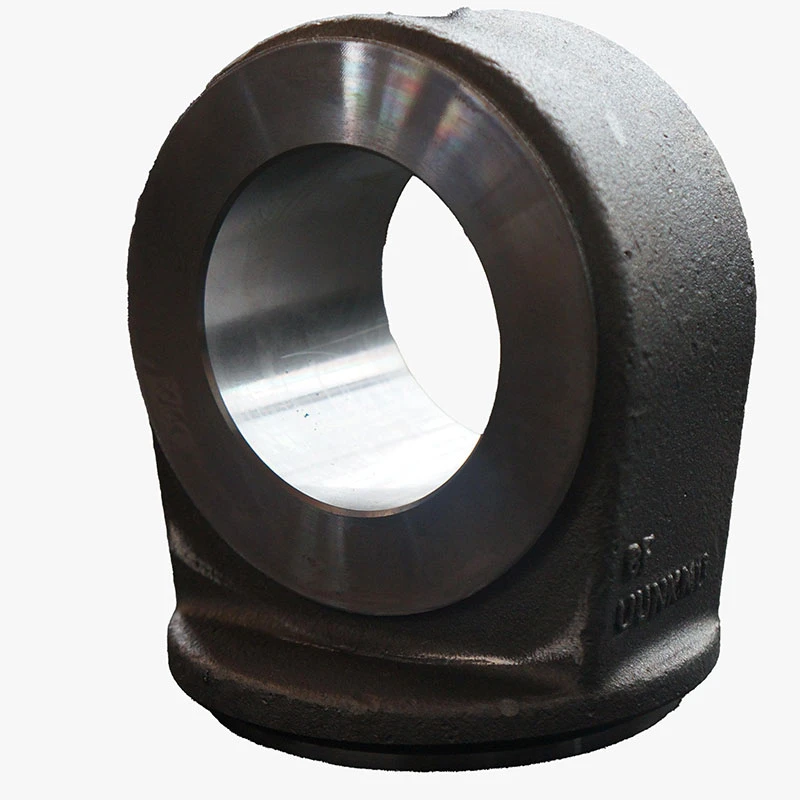

plaster of paris sand casting

Advantages of Plaster of Paris Sand Casting

- Precision The use of plaster captures intricate details, making this method ideal for artists and manufacturers who require high levels of specificity in their products.

- Cost-Effectiveness Using plaster molds can reduce costs compared to other molding materials, as plaster is inexpensive and easy to work with.

- Versatility This casting method is applicable across various industries, including art, manufacturing, jewelry design, and even the production of parts in automotive and aerospace sectors.

- Environmental Benefits Plaster of Paris and sand are both regarded as environmentally friendly materials. They can be sourced sustainably, and the end products can often be recycled.

Applications

The versatility and benefits of plaster of Paris sand casting have led to its widespread use in several applications

- Artistic Sculptures Many artists utilize this method to create detailed sculptures, allowing them to replicate designs accurately and achieve fine finishes.

- Product Prototyping Manufacturers often use this technique for rapid prototyping, enabling them to quickly produce and test new designs before full production.

- Architectural Elements Plaster of Paris casting is commonly employed to create ornamental elements in architecture, including decorative moldings, columns, and cornices.

Conclusion

Plaster of Paris sand casting represents a fruitful synergy of two powerful techniques in mold-making and casting. By combining the detail-oriented properties of plaster with the strength and practicality of sand, this method not only streamlines the casting process but also opens up a world of creative possibilities. Whether in artistic endeavors or industrial applications, plaster of Paris sand casting continues to be a reliable and cherished choice for those seeking precision and versatility in their projects.

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025