stamped steel parts

Understanding Stamped Steel Parts A Key Component in Modern Manufacturing

Stamped steel parts play a crucial role in the manufacturing industry, serving as foundational components in a myriad of products ranging from automotive to consumer electronics. This article delves into the processes, advantages, applications, and future of stamped steel parts, highlighting their significance in contemporary manufacturing.

What are Stamped Steel Parts?

Stamped steel parts are created through a manufacturing process that utilizes dies and presses to shape steel into specific forms. This method involves cutting, bending, and shaping steel sheets to produce components that meet precise specifications. The stamping process can be categorized into several types, including blanking, punching, bending, and forming, allowing for intricate designs and complex geometries.

Steel is an ideal material for stamping due to its remarkable strength, durability, and versatility. Various types of steel can be used in stamping processes, including carbon steel, stainless steel, and high-strength low-alloy steel. The choice of steel depends on the intended application and the mechanical properties required for the finished part.

Advantages of Stamped Steel Parts

One of the primary advantages of stamped steel parts is the ability to produce high volumes of components with exceptional consistency and precision. Stamping processes are highly automated, enabling manufacturers to achieve tight tolerances while minimizing material waste. This efficiency translates to lower production costs and faster turnaround times, making stamped steel an economically viable option for mass production.

Another key advantage is the strength-to-weight ratio of steel. Stamped steel parts are often lighter than their counterparts made from other materials, without sacrificing strength or durability. This attribute is particularly essential in industries such as automotive, where reducing weight can improve fuel efficiency and overall performance.

Additionally, stamped steel offers excellent design flexibility. The stamping process can accommodate a wide range of shapes and sizes, allowing engineers to create components tailored to specific functions. This adaptability is vital in industries requiring custom solutions to meet unique challenges.

stamped steel parts

Applications of Stamped Steel Parts

Stamped steel parts are ubiquitous in various sectors. In the automotive industry, they are used to create body panels, brackets, and structural components. The precision and strength of stamped parts contribute to vehicle safety and performance.

In the consumer electronics sector, stamped steel is employed in the production of housings, supports, and internal components. The lightweight nature of stamped steel enhances product portability without compromising structural integrity.

Moreover, stamped steel parts are essential in the construction industry, where they are used for brackets, connectors, and frames. Their reliability ensures that structures maintain stability and safety over time.

The Future of Stamped Steel Parts

As manufacturing continues to evolve, the future of stamped steel parts appears promising. Advances in automation and robotics are expected to further enhance the efficiency of the stamping process. Additionally, innovations in materials science may lead to the development of new steel alloys that offer even greater strength and lighter weights.

Sustainability is also becoming a priority in manufacturing, and stamped steel parts align well with eco-friendly practices. Steel can be recycled infinitely without loss of quality, making stamped components a sustainable choice in an increasingly environmentally-conscious market.

In conclusion, stamped steel parts are a fundamental element in modern manufacturing, offering vast benefits in terms of efficiency, strength, and design flexibility. Their widespread applications across various industries underscore their importance in creating reliable and high-performance products. As technology advances and manufacturing practices evolve, stamped steel parts will undoubtedly continue to play a pivotal role in shaping the future of production.

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

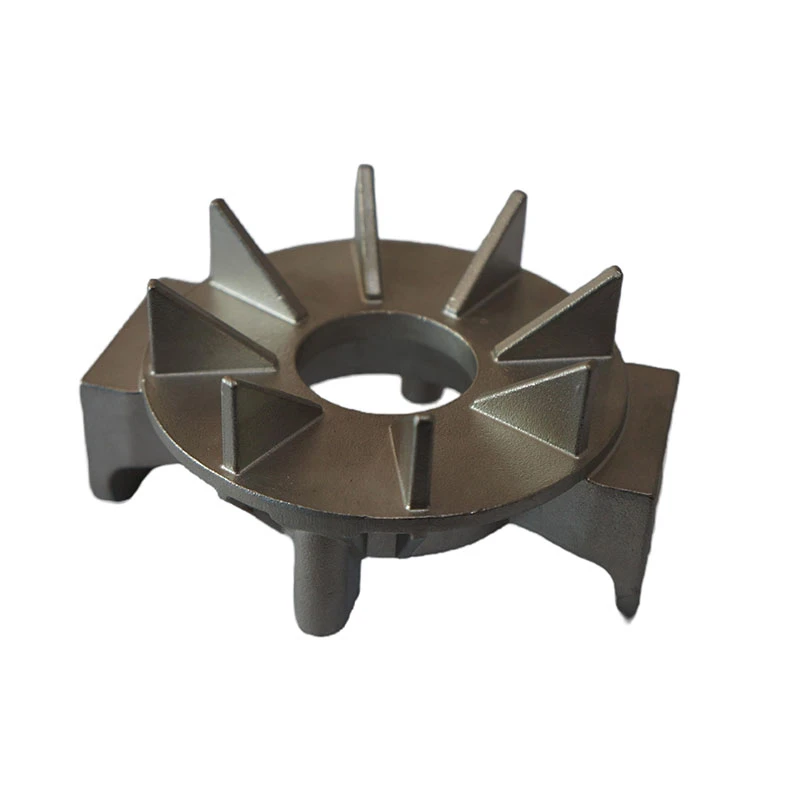

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025