Ene . 16, 2025 01:54

Back to list

precision casting manufacturers

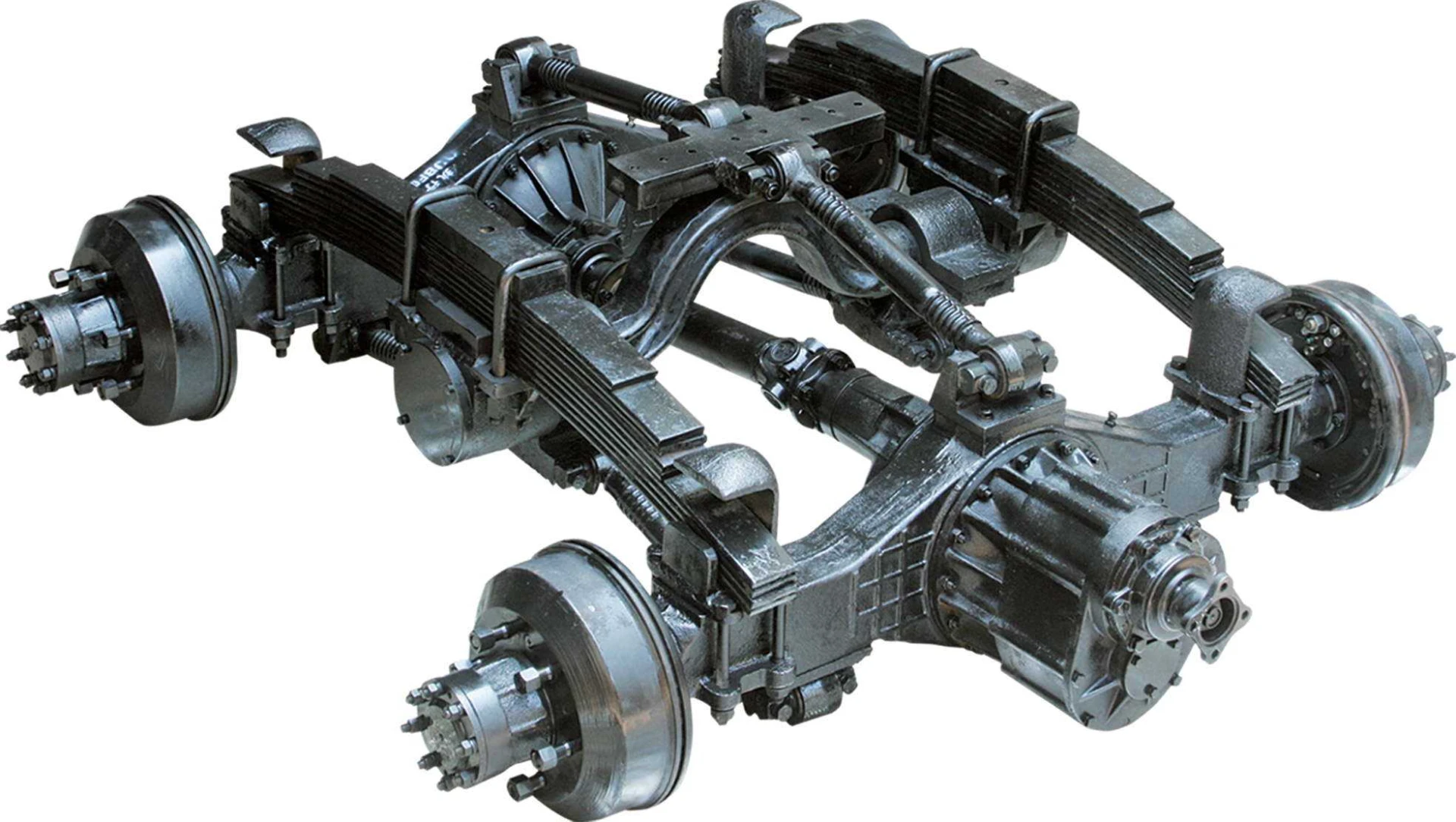

Precision casting, also known as investment casting, plays a crucial role in various industries, from aerospace to medical equipment manufacturing. Renowned for its ability to produce components with exceptional accuracy and surface finish, precision casting has set itself apart as a pioneer in delivering complex shapes and high-performance materials. The realm of precision casting manufacturers offers an intricate insight into the expertise and reliability required for delivering excellence.

One of the definitive advantages of precision casting is the ability to produce near-net shape components, reducing the need for extensive machining and thus minimizing material waste. This not only contributes to cost-efficiency but also aligns with growing environmental sustainability efforts. Manufacturers that are at the forefront of innovation adopt environmentally-responsible practices, including the use of recycled materials and energy-efficient production techniques. They are pioneers in integrating new technologies, such as rapid prototyping and 3D printing, to enhance the design and testing phase, allowing for quicker iterations and improved final products. Experience stands as a testament to a manufacturer’s ability to adapt and excel in an ever-evolving industry. Seasoned manufacturers leverage decades of experience to refine their processes and equipment, enabling them to solve challenging engineering problems. Their longevity in the industry is often backed by a roster of highly skilled personnel who continually advance the boundaries of what precision casting can achieve. This depth of experience translates into finely-tuned manufacturing strategies that deliver unparalleled precision, quality, and reliability. In summary, the world of precision casting manufacturers is marked by a blend of technical prowess, steadfast quality assurance, and unwavering client commitment. These manufacturers are not just producers of metal components; they are architects of engineered excellence, building the future of numerous industries one casting at a time. By prioritizing Experience, Expertise, Authoritativeness, and Trustworthiness, they stand as paragons of precision in a demanding and dynamic market.

One of the definitive advantages of precision casting is the ability to produce near-net shape components, reducing the need for extensive machining and thus minimizing material waste. This not only contributes to cost-efficiency but also aligns with growing environmental sustainability efforts. Manufacturers that are at the forefront of innovation adopt environmentally-responsible practices, including the use of recycled materials and energy-efficient production techniques. They are pioneers in integrating new technologies, such as rapid prototyping and 3D printing, to enhance the design and testing phase, allowing for quicker iterations and improved final products. Experience stands as a testament to a manufacturer’s ability to adapt and excel in an ever-evolving industry. Seasoned manufacturers leverage decades of experience to refine their processes and equipment, enabling them to solve challenging engineering problems. Their longevity in the industry is often backed by a roster of highly skilled personnel who continually advance the boundaries of what precision casting can achieve. This depth of experience translates into finely-tuned manufacturing strategies that deliver unparalleled precision, quality, and reliability. In summary, the world of precision casting manufacturers is marked by a blend of technical prowess, steadfast quality assurance, and unwavering client commitment. These manufacturers are not just producers of metal components; they are architects of engineered excellence, building the future of numerous industries one casting at a time. By prioritizing Experience, Expertise, Authoritativeness, and Trustworthiness, they stand as paragons of precision in a demanding and dynamic market.

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES