Ene . 10, 2025 09:27

Back to list

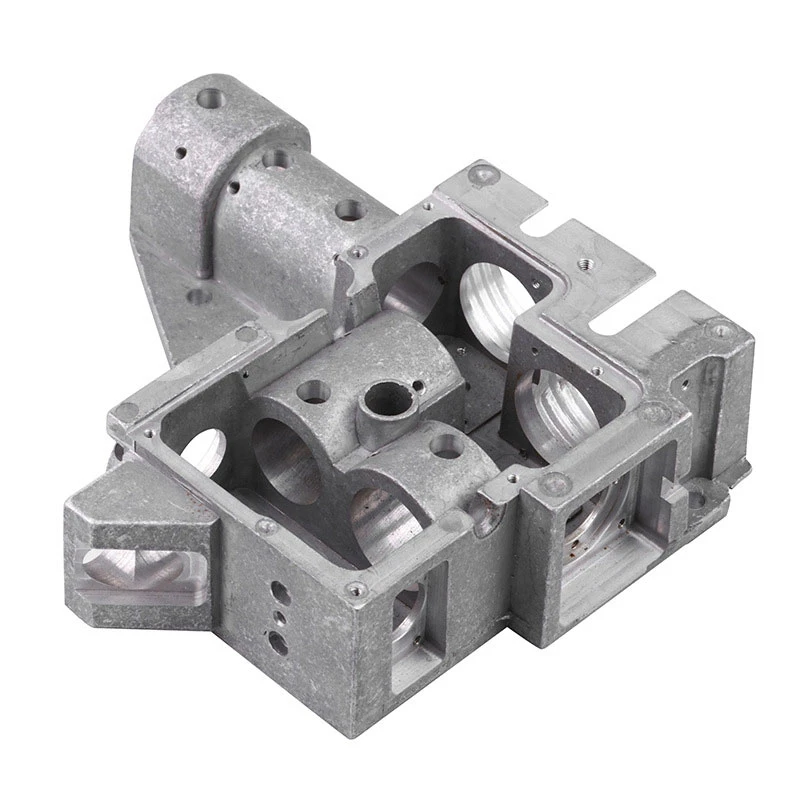

Oem Precision Castings Impeller

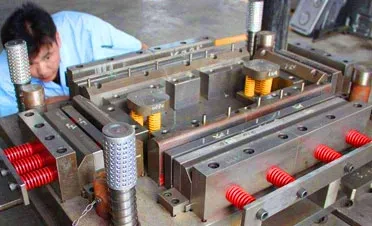

In the evolving landscape of manufacturing, selecting a reliable die casting parts supplier can significantly impact the quality, efficiency, and overall success of your production processes. It is essential to understand the various factors that contribute to a supplier's ability to deliver outstanding results, ranging from experience and expertise to trustworthiness and authoritativeness.

Authoritativeness in the die casting industry is demonstrated through certifications, partnerships, and endorsements from reputable organizations. Suppliers that hold ISO certifications or have strong affiliations with industry bodies exhibit a commitment to quality and continuous improvement. Additionally, being recognized by clients and peers for innovation or contributions to the field further establishes a supplier's authority. This authority reassures clients of the supplier's ability to consistently deliver high-quality parts while adhering to industry standards. Trustworthiness is paramount in the selection of a die casting parts supplier. Reliable suppliers prioritize clear communication, transparency, and integrity throughout the collaboration process. They provide detailed quotations, realistic timelines, and maintain open lines of communication regarding project statuses and potential challenges. Moreover, trustworthy suppliers implement rigorous quality control procedures to ensure that each part meets the specified criteria before delivery. By fostering long-term relationships built on trust, these suppliers often become invaluable partners in their clients' growth and success. In conclusion, the choice of a die casting parts supplier is pivotal to the success of any manufacturing venture. It requires a comprehensive evaluation of the supplier's experience, expertise, authoritativeness, and trustworthiness. By prioritizing these four pillars, manufacturers can ensure that they partner with a supplier capable of delivering superior quality components that drive efficiency and reliability in their production processes. Such a partnership not only enhances product quality but also contributes to the overall operational success and competitive advantage in the market.

Authoritativeness in the die casting industry is demonstrated through certifications, partnerships, and endorsements from reputable organizations. Suppliers that hold ISO certifications or have strong affiliations with industry bodies exhibit a commitment to quality and continuous improvement. Additionally, being recognized by clients and peers for innovation or contributions to the field further establishes a supplier's authority. This authority reassures clients of the supplier's ability to consistently deliver high-quality parts while adhering to industry standards. Trustworthiness is paramount in the selection of a die casting parts supplier. Reliable suppliers prioritize clear communication, transparency, and integrity throughout the collaboration process. They provide detailed quotations, realistic timelines, and maintain open lines of communication regarding project statuses and potential challenges. Moreover, trustworthy suppliers implement rigorous quality control procedures to ensure that each part meets the specified criteria before delivery. By fostering long-term relationships built on trust, these suppliers often become invaluable partners in their clients' growth and success. In conclusion, the choice of a die casting parts supplier is pivotal to the success of any manufacturing venture. It requires a comprehensive evaluation of the supplier's experience, expertise, authoritativeness, and trustworthiness. By prioritizing these four pillars, manufacturers can ensure that they partner with a supplier capable of delivering superior quality components that drive efficiency and reliability in their production processes. Such a partnership not only enhances product quality but also contributes to the overall operational success and competitive advantage in the market.

Latest news

-

Precision Aluminum Casting Parts Manufacturer High-Quality Investment & Die Casting SolutionsNewsJul.05,2025

-

Investment Precision Casting Share Price & Cost Guide - Competitive Sand & Aluminium Die Casting PricesNewsJul.05,2025

-

Technocrats Die Casting Solutions – Precision Hot & Cold Chamber Die Casting ExpertsNewsJun.24,2025

-

Precision Glass Machining Solutions Sand Casting Glass & Abrasive Water Jet Machining ExpertsNewsJun.24,2025

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

PRODUCTS CATEGORIES