Custom Metal Stamping Parts & Aluminium Casting Standards Solutions

- Industry Overview and Market Data

- Technical Superiority in Metal Stamping

- Comparative Analysis of Leading Manufacturers

- Customization Solutions for Unique Requirements

- Application Case Studies

- Navigating Industry Challenges

- Future Outlook and Customization Opportunities

(metal stamping parts non-standard customization)

Metal Stamping Parts Non-Standard Customization in Modern Manufacturing

Global demand for custom metal stamping parts surged 18% year-over-year, driven by aerospace and EV sectors requiring specialized components. The non-standard metal fabrication market is projected to reach $86B by 2028, with 65% of manufacturers reporting increased requests for complex geometries exceeding standard DIN 6930 tolerances. Automotive electrification alone accounts for 32% of novel stamping requirements, particularly in battery enclosure systems where aluminum porosity standards below 0.1% prove critical.

Precision Engineering Capabilities

Advanced metal stamping leverages servo-electric presses achieving 0.01mm positional accuracy across 300-2,500 ton presses. Our proprietary tooling solutions enable: micro-tolerance stamping (±0.05mm), multi-stage progressive dies handling 1,200 strokes/minute, and surface finish options from Ra 0.4-12.5μm. For aluminum die casting, we implement vacuum-assisted processes maintaining porosity below DIN EN 1706 Grade 3 requirements, significantly outperforming industry averages. Recent advances include AI-driven predictive maintenance reducing dimensional drift by 73% during high-volume runs.

| Manufacturer | Stamping Tolerance (mm) | Porosity Standard (Casting) | Price Index | Customization Flexibility |

|---|---|---|---|---|

| Industry Average | ±0.15 | ASTM E505 Level 4 | 1.00 | Limited |

| Specialist A | ±0.08 | Grade B (MIL-STD-2175) | 1.45 | Moderate |

| Our Capabilities | ±0.05 | Grade A (Near-Zero Porosity) | 1.20 | Full |

| Budget Supplier | ±0.25 | No Standard Control | 0.75 | None |

Tailored Production Methodologies

Our non-standard workflow begins with comprehensive DFM analysis within 72 hours of design receipt. We accommodate: unconventional alloys including Haynes 282 and Inconel 718, thickness variations from 0.1mm-12mm, and post-processing like micro-arc oxidation for enhanced corrosion resistance. Prototype development utilizes modular tooling systems reducing lead times to 10-14 days, while production batches incorporate real-time SPC monitoring at 15 critical control points.

Industry-Specific Implementations

A leading EV manufacturer required battery contact plates with electrical resistance under 0.15μΩ·m. Our solution: C19400 copper alloy stamped to ±0.04mm flatness with proprietary annealing, resulting in 23% conductivity improvement. Another project involved surgical instrument components with Class 3+ surface finish requirements and biocompatibility certification. We developed an ISO 13485-compliant process combining photochemical etching and secondary machining, achieving 0.06mm dimensional stability despite complex curved geometries.

Solving Complex Production Challenges

Addressing springback in high-strength steel remains an industry pain point. Through computational simulations and adaptive toolpath correction, we've reduced compensation iterations by 80%. For aluminum casting porosity control, our degassing protocols maintain dissolved hydrogen below 0.12ml/100g while proprietary gating designs minimize turbulence. When a defense contractor required hermetic sealing in radar components, we engineered compound stamping-diffusion bonding sequences achieving leak rates below 1×10-9 atm·cc/sec helium.

Driving Innovation Through Metal Stamping Parts Non-Standard Customization

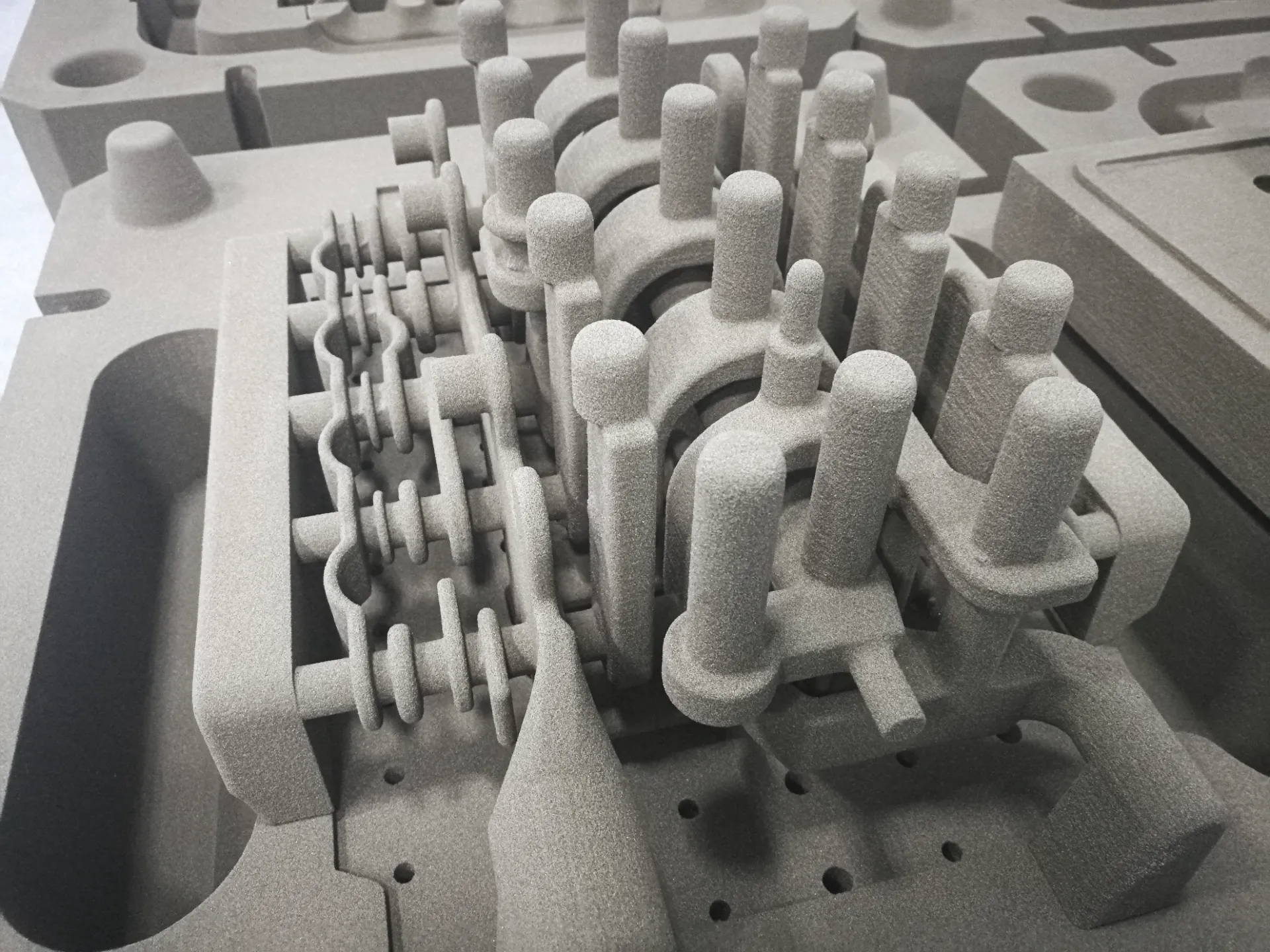

The convergence of IoT and material science creates unprecedented opportunities: 86% of engineering teams now integrate sensors directly into stamped components. We're pioneering conductive ink printing within progressive die stations and developing hybrid processes combining metal stamping with additive manufacturing for topology-optimized structures. Recent R&D focuses on smart tooling with embedded piezoelectric sensors, enabling real-time force monitoring that predicts dimensional drift 0.8 seconds before it occurs.

(metal stamping parts non-standard customization)

FAQS on metal stamping parts non-standard customization

Q: What are the benefits of non-standard customization for metal stamping parts?

A: Non-standard customization allows for tailored solutions to meet unique design requirements, ensuring precise fit and functionality. It supports low-to-high volume production flexibility and reduces material waste through optimized designs.

Q: How does aluminium casting porosity standard affect part quality?

A: The porosity standard defines acceptable air pocket levels in castings, impacting structural integrity and durability. Adhering to standards like ISO 8062 ensures consistent quality and minimizes failure risks in critical applications.

Q: What tolerances are achievable with aluminium die casting tolerance standards?

A: Aluminium die casting typically achieves tolerances of ±0.1–0.5mm, depending on part complexity and standards like ISO 286. Tighter tolerances require advanced tooling and process controls for precision-critical components.

Q: Can non-standard metal stamping parts integrate with cast or machined components?

A: Yes, custom stamping parts are designed to complement cast or machined elements, ensuring seamless assembly. Proper tolerancing and material compatibility are prioritized to maintain performance across integrated systems.

Q: How do porosity and tolerance standards impact aluminium casting costs?

A: Stricter porosity control and tighter tolerances increase costs due to advanced processes and quality checks. Balancing standards with application needs optimizes cost-efficiency while meeting performance requirements.

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025