machining manufacturer

The Evolution of Machining Manufacturers Meeting Modern Demands

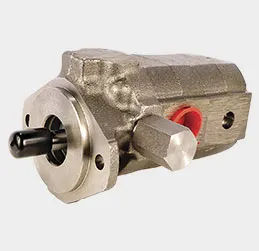

In the dynamic world of manufacturing, machining manufacturers occupy a crucial niche, responsible for transforming raw materials into precision-engineered components. This sector has evolved dramatically over the last few decades, driven by technological advancements, globalization, and ever-changing market demands. Understanding the intricacies of machining manufacturing is essential for recognizing its significance in today’s economy.

Historical Context

Machining processes, which include turning, milling, drilling, and grinding, have been employed for centuries. Initially, these methods were labor-intensive and relied heavily on human skill. The Industrial Revolution marked a major turning point, introducing mechanized machinery that significantly increased production efficiency. As technologies advanced, the role of machining manufacturers transformed from simple artisans to sophisticated producers capable of meeting complex industrial requirements.

Technological Advancements

One of the most significant influences on machining manufacturers has been the advent of Computer Numerical Control (CNC) technology. CNC machines enable high precision and can replicate intricate designs consistently, reducing the margin for error compared to traditional machining methods. Moreover, additive manufacturing—commonly known as 3D printing—has emerged as a revolutionary alternative, allowing manufacturers to create components layer by layer, thus minimizing waste and maximizing design possibilities.

Manufacturers are increasingly adopting Industry 4.0 principles, integrating IoT (Internet of Things) technologies into their operations. This connectivity facilitates real-time monitoring of machine performance and predictive maintenance, resulting in reduced downtime and increased efficiency. Furthermore, the data collected can provide insights into production processes, enabling manufacturers to optimize their systems continuously.

Globalization and Competition

machining manufacturer

The rise of globalization has dramatically transformed the landscape for machining manufacturers. With the ability to source materials and labor from across the globe, companies are now in direct competition with international manufacturers. This competition has led to an emphasis on cost efficiency, pushing many machining manufacturers to streamline their operations and adopt lean manufacturing practices.

Additionally, many companies are relocating their production facilities to regions where labor and operational costs are lower, capitalizing on the global supply chain. However, this move also requires manufacturers to navigate various regulatory environments and cultural differences, making adaptability an essential skill in today’s market.

Meeting Market Demands

The demands of industries such as aerospace, automotive, and medical devices have become more complex, requiring machining manufacturers to be agile and innovative. Customized solutions are increasingly sought after, and the ability to produce small batches of highly specialized products is now vital. This shift toward customization has challenged manufacturers to remain flexible in their production processes while ensuring the highest standards of quality.

Sustainability has also gained prominence. Modern machining manufacturers are exploring eco-friendly practices, from reducing waste during production to recycling materials whenever possible. Implementing energy-efficient machines and processes not only helps the environment but also often reduces operational costs, enhancing the overall profitability of the manufacturer.

Future Prospects

Looking ahead, the future of machining manufacturers appears promising, albeit challenging. The continuous evolution of technologies, such as artificial intelligence and advanced robotics, stands to further revolutionize the industry. Companies that embrace these innovations while maintaining a commitment to quality and customer satisfaction will likely thrive.

In conclusion, machining manufacturers play an indispensable role in the modern manufacturing landscape. As they adapt to technological advancements, global competition, and shifting market demands, their ability to innovate and efficiently produce high-quality components will define their success. The future will undoubtedly hold new challenges, but with a proactive approach, machining manufacturers can continue to be at the forefront of industrial progress.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025