fitting and machining

Fitting and Machining The Art and Science of Precision Engineering

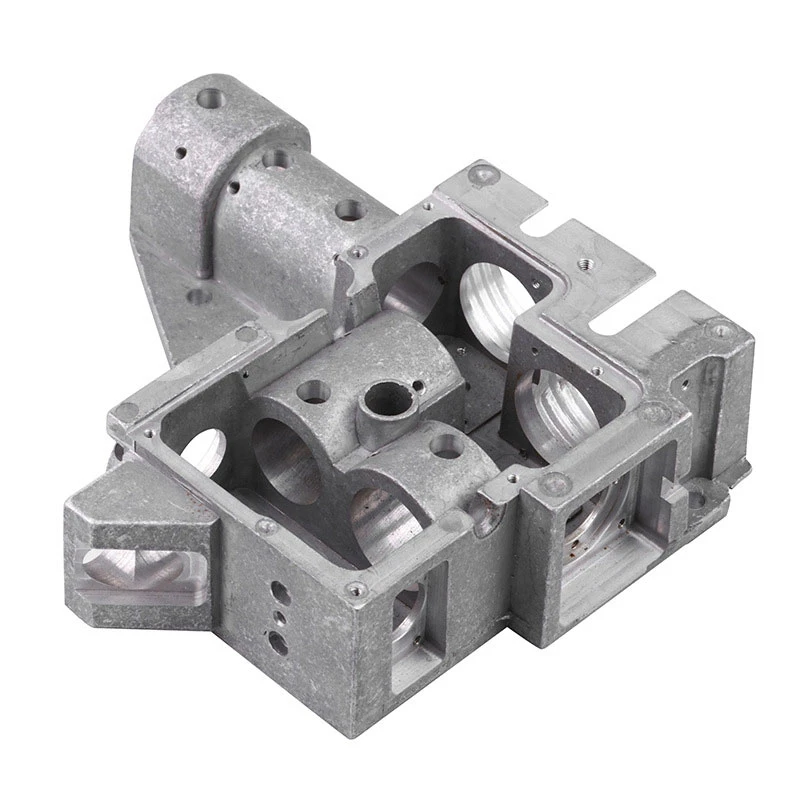

Fitting and machining are two fundamental processes in the realm of engineering that have a profound impact on manufacturing and construction industries. These processes are essential for assembling mechanical components with utmost precision, ensuring that parts fit together seamlessly to perform their intended functions. This article delves into the intricacies of fitting and machining, exploring their importance, techniques, and modern advancements.

Understanding Fitting and Machining

Fitting refers to the process of assembling two or more parts together to create a complete unit. It involves measuring, aligning, and securing components to ensure they function harmoniously without any interference. Machining, on the other hand, is a broader term that encompasses various manufacturing processes that involve the removal of material from a workpiece to achieve desired dimensions or surface finishes. Common machining processes include milling, turning, grinding, and drilling.

Both fitting and machining are essential in the production of mechanical systems, ranging from simple assemblies, such as furniture, to complex machinery, like engines and aircraft. The accuracy and quality of these processes significantly influence the performance, durability, and safety of the final products.

The Importance of Precision

In industries such as aerospace, automotive, and electronics, precision is paramount. Even the slightest misalignment or deviation in dimensions can lead to catastrophic failures. For instance, in aerospace engineering, a poorly fitted component in an aircraft can compromise flight safety. Therefore, engineers and machinists must adhere to strict tolerances and quality standards throughout the fitting and machining processes.

To achieve precision, various tools and instruments are employed, including calipers, micrometers, and machine tools equipped with advanced sensors. Computer Numerical Control (CNC) machines have revolutionized machining processes by providing unparalleled accuracy and repeatability. CNC technology allows for the automation of machining operations, resulting in less human error and higher production rates.

Techniques in Fitting and Machining

fitting and machining

Fitting techniques vary depending on the specific application and the materials involved. Traditional methods include hand fitting, where skilled craftsmen make adjustments using hand tools to achieve the desired fit. This approach is often employed in custom or low-volume productions.

Modern fitting techniques leverage technological advancements, such as laser scanning and 3D modeling, to create precise digital representations of components. These technologies enable engineers to simulate the assembly process, identifying potential issues before physical construction begins. Furthermore, additive manufacturing, commonly known as 3D printing, is increasingly being used to create components that require less fitting due to the higher accuracy of printed parts.

Machining techniques are equally diverse. Milling involves the use of rotating cutting tools to remove material from a workpiece, while turning uses a rotating workpiece and stationary cutting tool to shape cylindrical parts. Grinding is employed to achieve fine surface finishes and precise dimensions. Each machining technique has its advantages and applications, depending on the material, complexity, and required tolerances of the part being produced.

Challenges in Fitting and Machining

Despite advancements in technology, several challenges persist in fitting and machining processes. Material properties, such as hardness, ductility, and thermal stability, can affect the machinability of parts. Additionally, the increasing complexity of designs demands more sophisticated tooling and machining strategies. Managing these challenges requires continuous training and adaptation within the workforce, as well as investment in state-of-the-art machinery.

Moreover, sustainability has emerged as a critical concern in modern manufacturing. The fitting and machining processes can generate significant waste in terms of materials and energy consumption. As a result, companies are pursuing initiatives to minimize waste, recycle materials, and implement energy-efficient practices.

Conclusion

Fitting and machining remain integral processes in the engineering and manufacturing sectors, shaping the components that drive modern technology. As industries continue to evolve, the demand for precision and efficiency will only increase. By embracing new techniques and technologies, engineers and machinists can ensure that their work meets the high standards required for today’s complex systems. The future of fitting and machining lies in innovation, where traditional skills meet advanced technologies to create a new era of manufacturing excellence.

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025