Jan . 15, 2025 05:37

Back to list

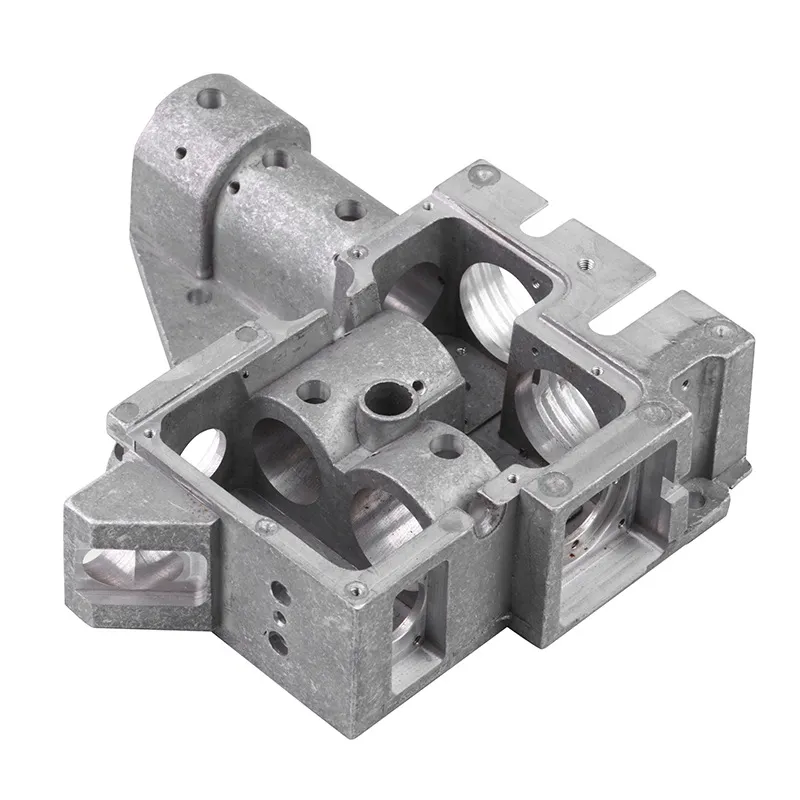

Oem Precision Castings Flange Joints

In the ever-evolving landscape of manufacturing, selecting a steel investment casting company holds the utmost significance. This intricate process, known for its exceptional detail and minimal material waste, demands not only technical proficiency but also the ability to understand customer needs and deliver reliable results. This article dives deep into what makes a steel investment casting company stand out, guiding industry professionals toward making informed decisions in their search for excellence.

Essential to every leading steel investment casting firm is a commitment to quality. They employ rigorous inspection processes, utilizing advanced technologies like X-ray radiography and 3D scanning to verify the integrity and dimensional accuracy of castings. A focus on continuous improvement through feedback loops and adopting cutting-edge casting methodologies reinforces their promise of superior quality. Furthermore, adaptability in meeting diverse client needs sets top companies apart. As industries evolve, so do design and performance requirements. A forward-thinking casting company invests in research and development, embracing innovations such as additive manufacturing and rapid prototyping to complement traditional casting techniques. This adaptability ensures they can accommodate varying levels of production volume, from small batches to high-volume runs, while maintaining competitive costs. Sustainability is becoming increasingly important, with many clients prioritizing environmentally responsible partners. Leading companies have embraced green initiatives, optimizing their casting processes to minimize waste and reduce emissions, contributing to both economic and environmental goals. Choosing the right steel investment casting company is a strategic decision that impacts the quality and performance of the final product. Prioritizing experience, expertise, authoritativeness, and trustworthiness when evaluating potential partners ensures a successful and enduring partnership, delivering cast components that meet the highest standards of precision, reliability, and sustainability.

Essential to every leading steel investment casting firm is a commitment to quality. They employ rigorous inspection processes, utilizing advanced technologies like X-ray radiography and 3D scanning to verify the integrity and dimensional accuracy of castings. A focus on continuous improvement through feedback loops and adopting cutting-edge casting methodologies reinforces their promise of superior quality. Furthermore, adaptability in meeting diverse client needs sets top companies apart. As industries evolve, so do design and performance requirements. A forward-thinking casting company invests in research and development, embracing innovations such as additive manufacturing and rapid prototyping to complement traditional casting techniques. This adaptability ensures they can accommodate varying levels of production volume, from small batches to high-volume runs, while maintaining competitive costs. Sustainability is becoming increasingly important, with many clients prioritizing environmentally responsible partners. Leading companies have embraced green initiatives, optimizing their casting processes to minimize waste and reduce emissions, contributing to both economic and environmental goals. Choosing the right steel investment casting company is a strategic decision that impacts the quality and performance of the final product. Prioritizing experience, expertise, authoritativeness, and trustworthiness when evaluating potential partners ensures a successful and enduring partnership, delivering cast components that meet the highest standards of precision, reliability, and sustainability.

Latest news

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Precision Engineering, Industrial EfficiencyNewsJul.13,2025

-

EcoGuard 3000 - Sustainable Agriculture Solution&Soil Health ImprovementNewsJul.13,2025

-

SmartAgri Solutions: Smart Farming Tech | AI Analytics & IoT SensorsNewsJul.13,2025

-

[Product Name]-[Company Name]|Business Efficiency&InnovationNewsJul.13,2025

-

Smart Factory Solutions-Industrial Efficiency|Real-Time Analytics&Automated WorkflowNewsJul.12,2025

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Durable, Reliable, CustomizedNewsJul.12,2025

PRODUCTS CATEGORIES