Feb . 18, 2025 06:34

Back to list

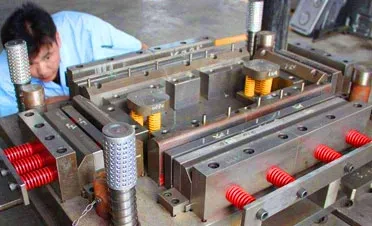

custom metal stamping parts

In the world of manufacturing, precision and efficiency are imperative, particularly when it comes to the creation of stamped sheet metal parts. These components serve as foundational elements across numerous industries, from automotive and aerospace to electronics and consumer goods. Their ubiquity and complexity necessitate a profound understanding of the stamping process, underpinned by years of expertise and industry-leading practices.

Experience in tackling complex projects bolsters trustworthiness. A seasoned manufacturer understands that each project is unique, requiring a bespoke approach. From prototyping to mass production, every stage is overseen with meticulous attention to detail, ensuring that the final product aligns with client expectations. Collaboration with clients throughout the process not only ensures satisfaction but also encourages a culture of transparency and trust. Furthermore, expertise is demonstrated through the ability to innovate and adapt. The integration of digital solutions like Industry 4.0 technologies, including IoT and data analytics, enhances operational efficiency. These technologies enable real-time monitoring of production processes, predictive maintenance of machinery, and enhanced quality control, which collectively reduce downtime and improve product consistency. Authoritativeness stems from a commitment to continuous improvement and research. Engaging with industry forums, participating in workshops, and staying abreast with technological advancements are critical. This ongoing process of learning and adaptation ensures that manufacturers not only meet but exceed industry standards, reinforcing their position as leaders in the field. Finally, an authoritative manufacturing entity understands the importance of robust supply chain management. Building strong relationships with reliable suppliers of raw materials ensures a steady, quality supply, which is critical for maintaining production schedules and meeting client demands. Trust is also cultivated through rigorous testing and quality checks at various stages of the production line, ensuring that any discrepancies are rectified before parts reach the end customer. In sum, the production of stamped sheet metal parts is an intricate process that combines deep expertise, technological prowess, and steadfast quality assurance. Through innovation, compliance with global standards, and a firm commitment to sustainability and client collaboration, manufacturers not only deliver exceptional products but also build enduring trust and authority in the industry.

Experience in tackling complex projects bolsters trustworthiness. A seasoned manufacturer understands that each project is unique, requiring a bespoke approach. From prototyping to mass production, every stage is overseen with meticulous attention to detail, ensuring that the final product aligns with client expectations. Collaboration with clients throughout the process not only ensures satisfaction but also encourages a culture of transparency and trust. Furthermore, expertise is demonstrated through the ability to innovate and adapt. The integration of digital solutions like Industry 4.0 technologies, including IoT and data analytics, enhances operational efficiency. These technologies enable real-time monitoring of production processes, predictive maintenance of machinery, and enhanced quality control, which collectively reduce downtime and improve product consistency. Authoritativeness stems from a commitment to continuous improvement and research. Engaging with industry forums, participating in workshops, and staying abreast with technological advancements are critical. This ongoing process of learning and adaptation ensures that manufacturers not only meet but exceed industry standards, reinforcing their position as leaders in the field. Finally, an authoritative manufacturing entity understands the importance of robust supply chain management. Building strong relationships with reliable suppliers of raw materials ensures a steady, quality supply, which is critical for maintaining production schedules and meeting client demands. Trust is also cultivated through rigorous testing and quality checks at various stages of the production line, ensuring that any discrepancies are rectified before parts reach the end customer. In sum, the production of stamped sheet metal parts is an intricate process that combines deep expertise, technological prowess, and steadfast quality assurance. Through innovation, compliance with global standards, and a firm commitment to sustainability and client collaboration, manufacturers not only deliver exceptional products but also build enduring trust and authority in the industry.

Prev:

Next:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES