rapid sand casting

Rapid Sand Casting Revolutionizing Metal Casting Techniques

Rapid sand casting is an innovative manufacturing process that significantly enhances the traditional methods of metal casting. This technique combines the age-old practice of sand casting with modern rapid prototyping technologies to create high-quality metal parts in a faster and more efficient manner. As industries increasingly seek faster production times and lower costs, rapid sand casting has emerged as a viable solution for various applications, from automotive to aerospace and beyond.

The Basics of Sand Casting

To understand rapid sand casting, it is essential to first grasp the fundamentals of traditional sand casting. The process involves creating a pattern of the desired part, which is then encased in sand to form a mold. Once the mold is prepared, molten metal is poured into it and allowed to cool and solidify. Finally, the mold is broken apart to reveal the finished cast part. Traditional sand casting is renowned for its versatility, as it can accommodate a wide range of metal alloys and complex geometries.

The Evolution Introducing Speed

While conventional sand casting has been effective for many years, it often suffers from long lead times due to the manual nature of pattern creation and mold preparation. This is where rapid sand casting comes into play. By leveraging advanced technologies such as 3D printing, manufacturers can create patterns and molds with unprecedented speed. The use of digital design tools allows for quick iterations and modifications, meaning that prototypes can be developed in days rather than weeks.

Rapid sand casting typically employs various rapid prototyping techniques, including 3D printing, to produce sand molds directly from a digital file. This approach not only accelerates the production timeline but also reduces the labor intensity of the process. The ability to create intricate designs without additional tooling means that manufacturers can take advantage of design complexities that were previously challenging or impossible to achieve with traditional methods.

Advantages of Rapid Sand Casting

rapid sand casting

One of the primary benefits of rapid sand casting is its ability to reduce lead times. In today’s fast-paced market, the quicker companies can bring products to market, the better their competitive edge. Rapid sand casting facilitates the rapid development of prototypes and production-ready parts, making it an attractive option for industries that require agility and responsiveness.

Furthermore, rapid sand casting can result in cost savings. Traditional casting methods often involve significant setup costs associated with creating molds and patterns. By eliminating these costs through the use of 3D-printed molds, manufacturers can achieve lower overall production costs, especially for smaller batch sizes, where traditional methods would be prohibitively expensive.

Quality is another aspect that benefits from rapid sand casting. The use of precise 3D printing technologies allows for a higher degree of accuracy and repeatability in the molds, leading to improved surface finishes and dimensional consistency in the final cast parts. This translates into better overall performance and reduced machining requirements, further enhancing production efficiency.

Applications and Future Trends

Rapid sand casting has found applications in various sectors, including automotive, aerospace, consumer products, and industrial machinery. Companies are increasingly adopting this technology to produce everything from engine components to custom artistic pieces. As the demand for customized solutions and rapid turnaround increases, the relevance of rapid sand casting will only continue to grow.

Looking forward, advancements in material science and 3D printing technologies are likely to further enhance the capabilities of rapid sand casting. The development of new sand materials and binders will improve mold durability and performance. Additionally, the integration of artificial intelligence and machine learning in the design and production process will streamline operations and optimize outcomes.

Conclusion

Rapid sand casting is a transformative approach to the metal casting industry, marrying the strengths of traditional sand casting with cutting-edge technology. By enabling faster production, reducing costs, and improving quality, it stands as a testament to how innovation can drive efficiency and competitiveness in manufacturing. As industries continue to evolve, rapid sand casting may very well be at the forefront of next-generation casting solutions, paving the way for a new era of manufacturing excellence.

-

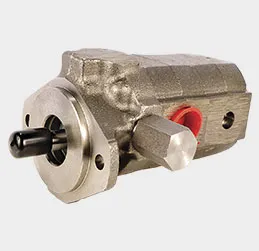

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025