precision stamping part

Understanding Precision Stamping Parts A Key Component in Modern Manufacturing

Precision stamping parts have become an integral aspect of modern manufacturing environments. They play a significant role across various industries including automotive, aerospace, electronics, and medical devices. The demand for precision stamped parts is rising due to the need for high-quality, reliable components that fit stringent specifications. This article delves into the intricacies of precision stamping, the advantages it offers, and its applications in various sectors.

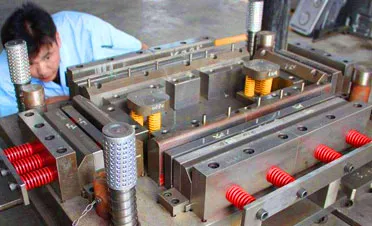

What is Precision Stamping?

Precision stamping is a manufacturing process that involves the use of specialized machinery to create intricate and detailed parts from metal sheets. The metal is pressed into shape using a die, allowing for a high degree of accuracy and repeatability. This process can be used to produce a wide range of components, from simple brackets to complex, multi-faceted parts.

The process itself is highly versatile. It can be performed on various metal materials including steel, aluminum, brass, and copper, thus accommodating diverse project requirements. The capabilities of precision stamping include bending, punching, and deep drawing, each allowing designers and engineers to create customized solutions tailored to specific needs.

Advantages of Precision Stamping

1. High Accuracy and Consistency One of the standout benefits of precision stamping is the high level of accuracy it provides. Parts manufactured through this method maintain tight tolerances, ensuring that each component meets required specifications. This is particularly crucial in industries such as aerospace and automotive, where even the slightest discrepancy can result in significant performance issues.

2. Cost-Effectiveness Precision stamping is often more economical compared to other manufacturing processes, especially when producing large quantities. Once the initial setup is complete, production runs can be executed efficiently, reducing labor and material costs. This cost-effectiveness makes it an attractive option for businesses looking to streamline their production processes.

3. Complex Geometries Unlike traditional methods, precision stamping allows manufacturers to create intricate designs that may be challenging to achieve through machining or casting. This capability enables innovation and creativity in product design, resulting in better functionality and performance of the final product.

precision stamping part

4. Material Optimization Precision stamping minimizes waste. By maximizing the use of the sheet metal, manufacturers can cut down on excess material usage, which also contributes to lower production costs and a smaller environmental footprint.

5. Rapid Production The advanced machinery used in precision stamping allows for quick turnaround times on projects. This rapid production capability meets the demands of industries that require prompt delivery of components.

Applications of Precision Stamping Parts

Precision stamping parts are used in a wide variety of applications. In the automotive industry, these components are crucial for producing everything from brackets and clips to complex engine components. The healthcare sector also relies on precision stamping for the manufacture of parts used in medical devices, ensuring high reliability and safety standards.

In consumer electronics, companies utilize precision stamping to create parts for devices like smartphones, televisions, and laptops, where compact and lightweight designs are essential. Similarly, the aerospace industry benefits from precision stamped components, as they often require lightweight yet durable parts for optimal aircraft performance.

Conclusion

In conclusion, precision stamping parts represent a cornerstone of modern manufacturing practices. Their ability to produce high-quality, accurate, and cost-effective components makes them indispensable in various industries. As technology advances, the capabilities of precision stamping are likely to expand further, driving innovation and improving manufacturing processes. For businesses looking to enhance their production efficiency and product quality, investing in precision stamping can provide substantial benefits, ensuring they remain competitive in an ever-evolving market.

Whether it's improving performance in the automotive sector or supporting technological innovations in consumer electronics, the role of precision stamping cannot be overstated—it is a pivotal element that underpins the machinery of modern production.

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025