Feb . 10, 2025 09:29

Back to list

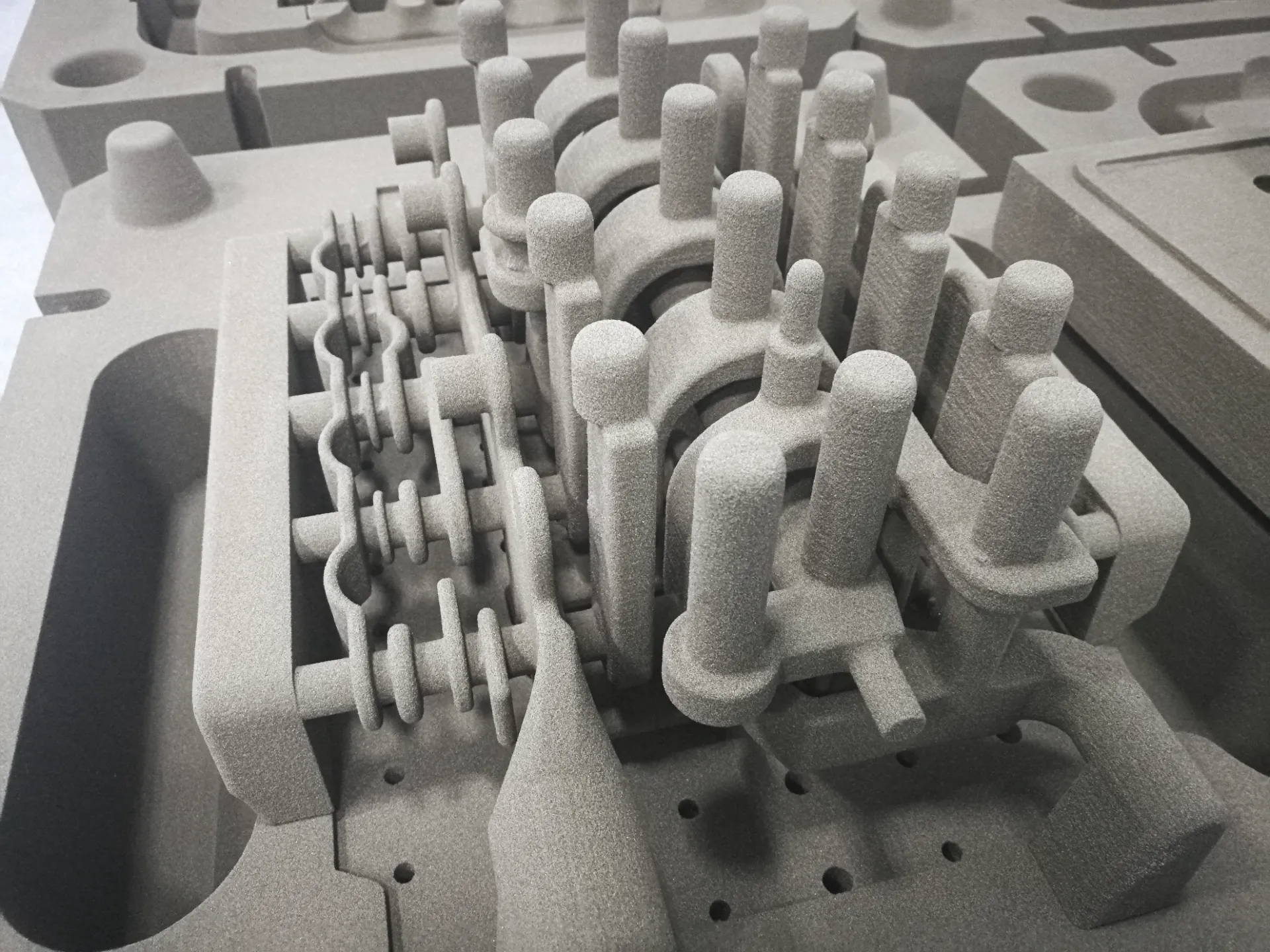

iron casting sand

Iron casting sand is an essential component in the metal casting industry, serving as the foundation for creating precise and durable metal molds. The intricacies involved in selecting, processing, and applying sand for iron casting demand an insight into industry expertise, catering to various specific requirements for successful casting results. This article explores the nuanced processes and criteria driving the effective use and selection of iron casting sand, underscoring its paramount significance in metalwork.

Moreover, the sustainability of sand sourcing and reclamation is increasingly prioritized within the industry. There's a growing emphasis on not only choosing the right type of sand for performance purposes but also ensuring it aligns with environmentally responsible practices. Experts in the field are steering innovations toward efficient sand reclamation systems, reducing dependency on natural deposits and minimizing ecological impact. This environmentally conscious approach not only appeals to regulatory standards but also bolsters a company’s reputation as a trustworthy and forward-thinking entity. In alignment with authoritative standards and regulations, quality control is paramount throughout the casting process, where the characteristics and utility of iron casting sand are meticulously monitored. Reputable institutions often provide certification and testing services, ensuring that the chosen sand meets industry standards and fulfills specific casting requirements. This authoritative supervision instills confidence throughout the supply chain, enhancing trust in the final product’s quality and reliability. In conclusion, the application of iron casting sand involves a synthesis of detailed expertise, authoritative insight, and a commitment to sustainable and quality-driven practices. The appropriate selection and processing of sand are foundational to achieving optimal casting results, underscoring the intricate interplay between various technical and environmental considerations. Establishing trustworthiness in these processes hinges upon a deep-rooted understanding of material properties, technological advancements, and an unwavering commitment to quality and environmental stewardship.

Moreover, the sustainability of sand sourcing and reclamation is increasingly prioritized within the industry. There's a growing emphasis on not only choosing the right type of sand for performance purposes but also ensuring it aligns with environmentally responsible practices. Experts in the field are steering innovations toward efficient sand reclamation systems, reducing dependency on natural deposits and minimizing ecological impact. This environmentally conscious approach not only appeals to regulatory standards but also bolsters a company’s reputation as a trustworthy and forward-thinking entity. In alignment with authoritative standards and regulations, quality control is paramount throughout the casting process, where the characteristics and utility of iron casting sand are meticulously monitored. Reputable institutions often provide certification and testing services, ensuring that the chosen sand meets industry standards and fulfills specific casting requirements. This authoritative supervision instills confidence throughout the supply chain, enhancing trust in the final product’s quality and reliability. In conclusion, the application of iron casting sand involves a synthesis of detailed expertise, authoritative insight, and a commitment to sustainable and quality-driven practices. The appropriate selection and processing of sand are foundational to achieving optimal casting results, underscoring the intricate interplay between various technical and environmental considerations. Establishing trustworthiness in these processes hinges upon a deep-rooted understanding of material properties, technological advancements, and an unwavering commitment to quality and environmental stewardship.

Prev:

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES