Feb . 13, 2025 12:21

Back to list

aluminium gravity die casting

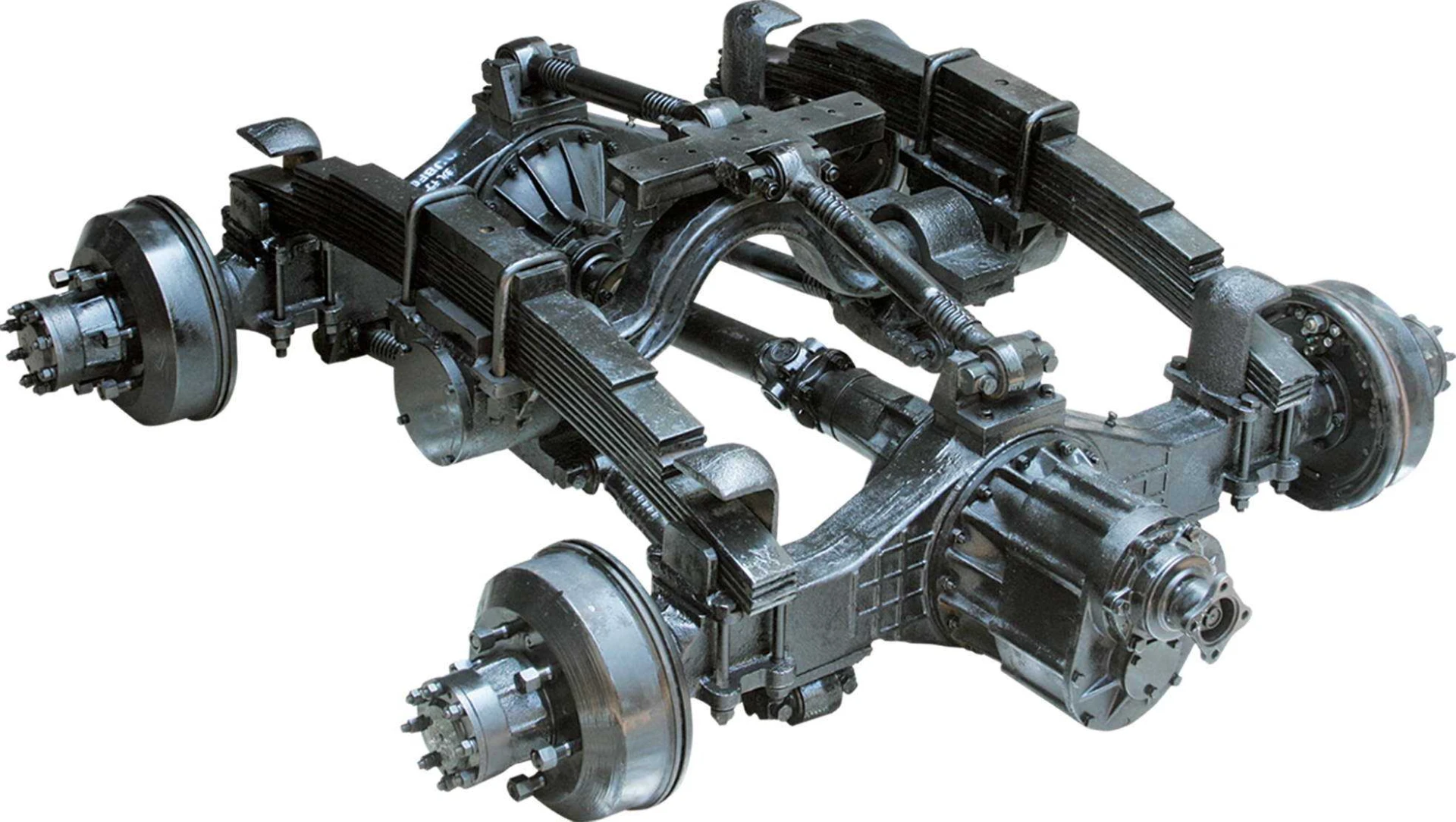

Gravity casting aluminum stands as a pivotal technique in the realm of product manufacturing, especially for industries demanding precision and durability. This method involves pouring molten aluminum into a preformed metal mold, utilizing the force of gravity to ensure the metal fills the cavity completely. Its significance extends across automotive, aerospace, and consumer goods sectors, where it ensures components exhibit excellent structural integrity and precise dimensions.

Our organization's authority in gravity casting is underscored by our state-of-the-art production facilities and a team of expert metallurgists who continuously refine casting techniques. Our adherence to international quality standards ensures that every product manufactured is both reliable and high-performing. We have collaborated with leading automotive manufacturers to deliver aluminum castings that meet rigorous safety and performance standards. Through continuous research and development, we have pioneered innovations in mold design and thermal management during the casting process, earning us a reputable stature in the global market. Trustworthiness is built on our unwavering commitment to quality and precision. Our gravity casting processes are ISO certified, assuring our clients of compliance with the highest industry standards. Every casting batch undergoes stringent quality control measures, utilizing the latest non-destructive testing methods to check for defects or irregularities. This meticulous approach is fundamental in establishing long-term partnerships with our clients, fostering a relationship built on trust and reliability. In conclusion, gravity casting aluminum is not just a manufacturing process but a catalyst for precision and efficiency in the production of high-caliber components. With profound experience and specialized expertise, our company provides authoritative and trustworthy solutions that meet the evolving demands of the modern industry. The benefits of reduced costs, better mechanical properties, and the ability to produce complex, resilient components make gravity casting an invaluable method in aluminum manufacturing. As industries continue to seek quality and innovation, gravity casting aluminum remains at the forefront of meeting these needs with unparalleled effectiveness.

Our organization's authority in gravity casting is underscored by our state-of-the-art production facilities and a team of expert metallurgists who continuously refine casting techniques. Our adherence to international quality standards ensures that every product manufactured is both reliable and high-performing. We have collaborated with leading automotive manufacturers to deliver aluminum castings that meet rigorous safety and performance standards. Through continuous research and development, we have pioneered innovations in mold design and thermal management during the casting process, earning us a reputable stature in the global market. Trustworthiness is built on our unwavering commitment to quality and precision. Our gravity casting processes are ISO certified, assuring our clients of compliance with the highest industry standards. Every casting batch undergoes stringent quality control measures, utilizing the latest non-destructive testing methods to check for defects or irregularities. This meticulous approach is fundamental in establishing long-term partnerships with our clients, fostering a relationship built on trust and reliability. In conclusion, gravity casting aluminum is not just a manufacturing process but a catalyst for precision and efficiency in the production of high-caliber components. With profound experience and specialized expertise, our company provides authoritative and trustworthy solutions that meet the evolving demands of the modern industry. The benefits of reduced costs, better mechanical properties, and the ability to produce complex, resilient components make gravity casting an invaluable method in aluminum manufacturing. As industries continue to seek quality and innovation, gravity casting aluminum remains at the forefront of meeting these needs with unparalleled effectiveness.

Next:

Latest news

-

Precision Machining & Manufacturing | Aerospace ExpertsNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision, Quality, CustomizationNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun|Precision Customization&Reliable Fluid ControlNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Fluid Control, CustomizableNewsAug.05,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Customization, Quality AssuranceNewsAug.05,2025

PRODUCTS CATEGORIES