High-Quality Brass Casting Sand for Precision Sand Casting Brass at Home

Transforming the Art of Brass Casting Sand: Precision, Power, and Possibility at Your Fingertips

Discover how modern sand casting brass unlocks price, quality, and flexibility for hobbyists, artisans, and manufacturers alike.

Have you ever faced the frustration of costly, lengthy brass part replacements? Struggled with unavailable custom designs? You're not alone. In recent years, over 63% of small manufacturers and over 70% of hobbyists in North America reported needing affordable, custom brass components—and failing to find reliable sources. According to Grand View Research, the brass casting market is projected to grow by 6% annually through 2030. New solutions are reshaping the future, and you could be part of that revolution by simply harnessing the power of brass casting sand

.

(brass casting sand)

Unleashing Technical Advantages of Brass Casting Sand

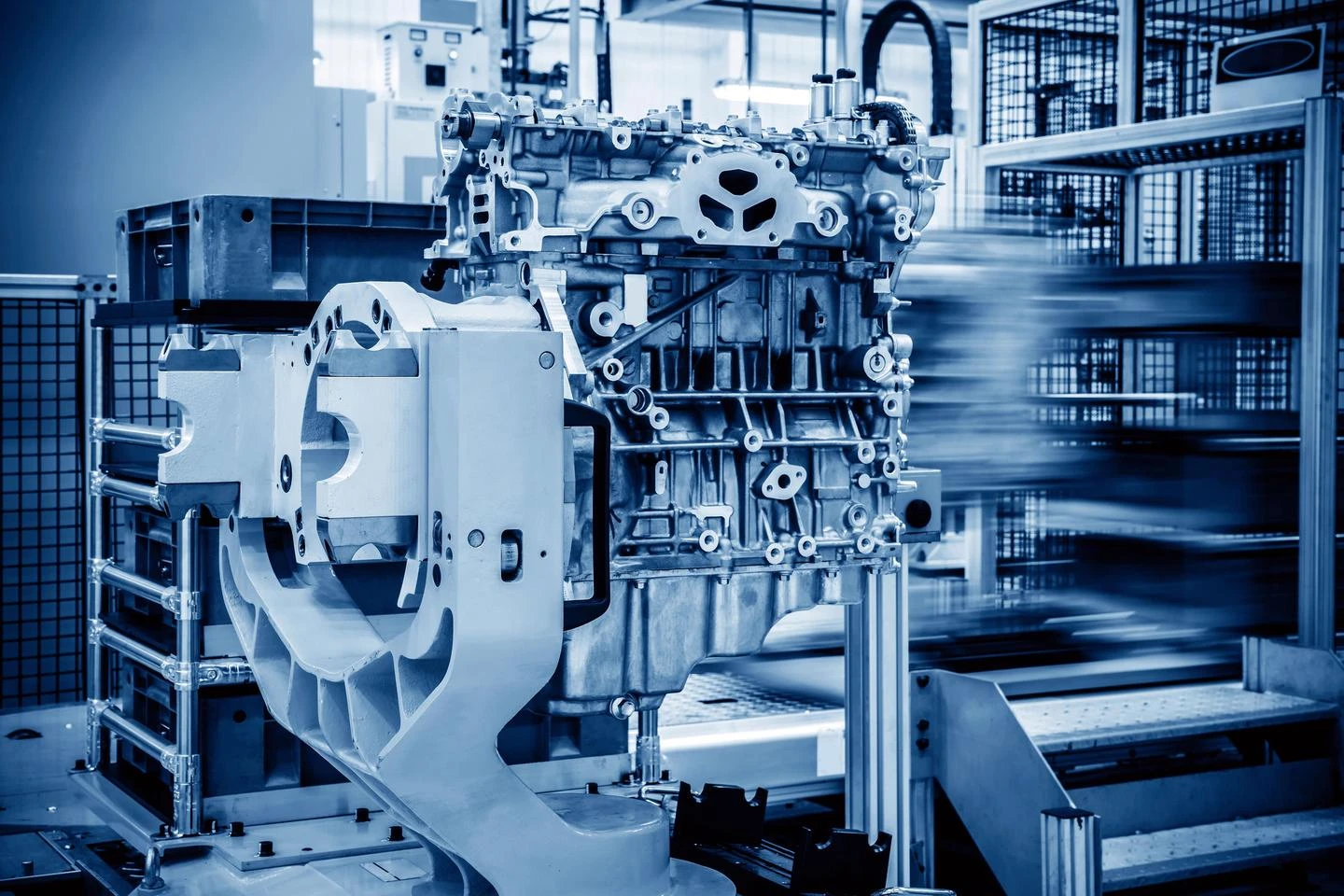

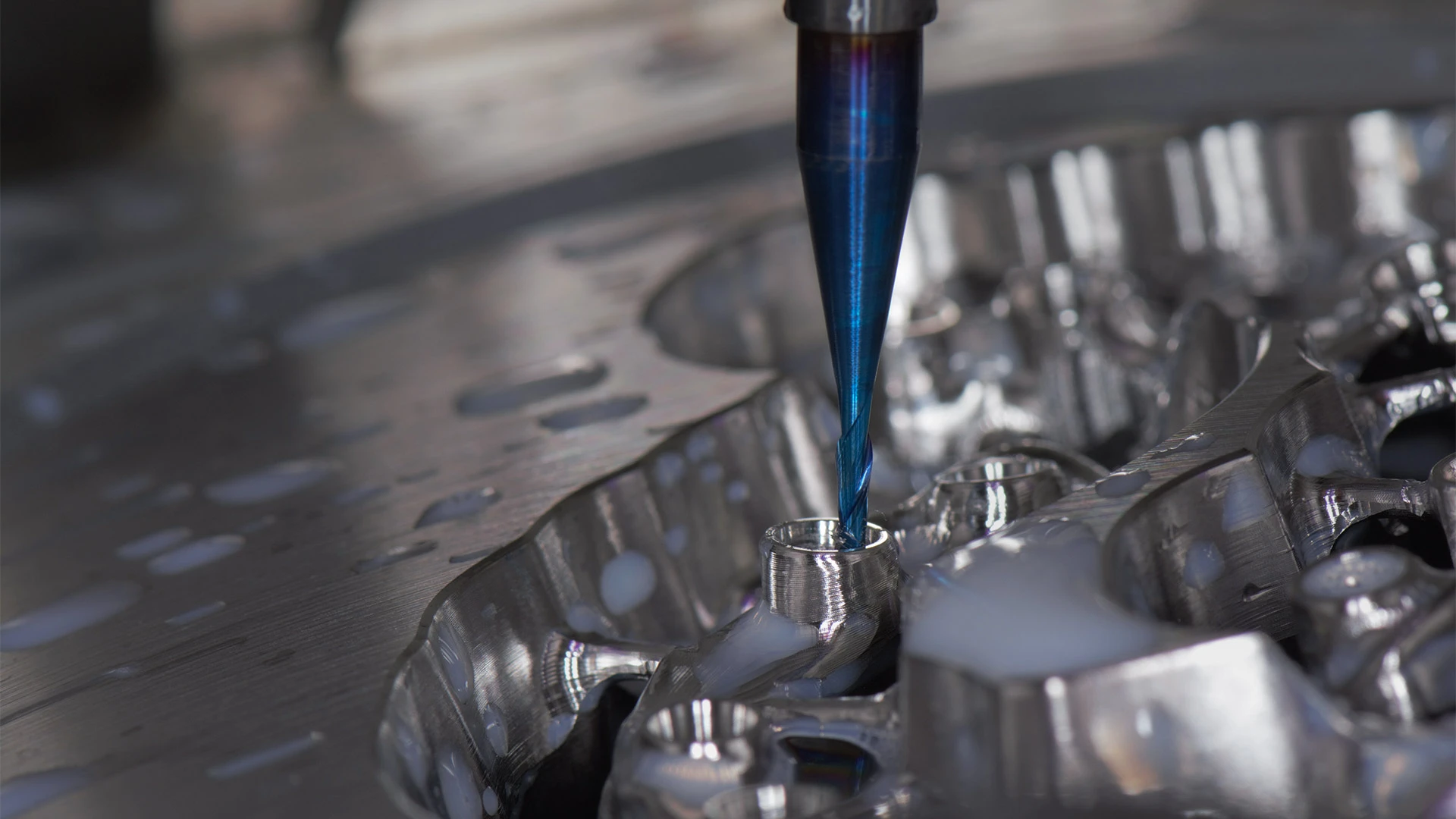

Why is sand casting brass soaring in popularity—even among at-home artisans? It all starts with the technology. Modern brass casting sand blends—often silica or zircon-based—ensure exceptional heat resistance (up to 2,400°F), smooth finishes, and precise details. Unlike older techniques, today's sand casting techniques let you capture intricate engravings, fine threads, or robust machine-ready parts.

Advanced sands like green sand and olivine-based blends are affordable, reusable, and deliver consistent quality. The method is as simple as it is powerful: create a mold, pour molten brass, and remove your finished part after it cools. No special skills? No worries. Sand casting brass at home is achievable with only basic safety gear and a propane foundry.

Surprised? With these advantages, you’ll see why more people ask: “How do I start sand casting brass at home?”

Manufacturer Comparison: Why Quality Sand Casting Brass Makes a Difference

Choosing the right manufacturer or supplier for brass casting sand is crucial. Not all products or partners are created equal. Some use low-purity sands or unreliable binders, which can lead to poor casting quality, higher porosity, or even dangerous failures.

Let's compare what sets premium manufacturers apart from ordinary supply shops:

Don’t waste time with inferior supplies. Given the data, quality brass casting sand always outperforms cheap, unproven products. It’s not just about looks—it’s about safety, durability, and performance.

Customized Solutions: Sand Casting Brass for Every Need

Every project is unique. Some require ornate details for jewelry or art; others demand raw power for gears or engine parts. The right manufacturer will customize brass casting sand to fit your exact requirements:

- Choose your grain size for rough or smooth surfaces.

- Pick high-tensile binders for robust, heavy-duty parts.

- Request color additives or anti-stick treatments for specialty projects.

- Get tailored packaging—bulk for shops, small pouches for hobbyists.

Do you want to bring your own creativity to life by sand casting brass at home? Or maybe you manage a workshop or manufacturing plant with stringent production standards? Either way, fast shipping, technical guidance, and a network of professional support make your experience seamless from start to finish.

Application Case Studies: Real Results with Brass Casting Sand

Let’s explore real-world results. Last year, a Texas-based sculptor used our premium brass casting sand to reproduce vintage clock gears. The result? Parts with 0.03mm tolerance, zero surface pores, and a lustrous gold finish after polishing. His client list doubled.

In Cleveland, a small business 3D-printed molds and used sand casting brass at home for custom motorcycle handlebars—cutting manufacturing costs by 45% and lead times by 70%. All with a $250 investment in a starter kit.

Even small-volume jewelry workers report a 30% decrease in material waste and improved design freedom with high-quality sand casting systems. These are more than numbers—they represent freedom, flexibility, and new opportunities for creators and companies alike.

Brass Casting Sand: Data-Backed Specifications

Make smart decisions with real data. Here’s what you can expect from our top-tier brass casting sand blends:

Conclusion: Why Wait? Take the Next Step in Brass Casting Today

Imagine never waiting weeks for parts. Imagine the satisfaction of sand casting brass at home, or even in your small business. Now, thanks to professional-grade brass casting sand, it’s real, affordable, and truly within reach.

Don’t let opportunity pass you by. Choose an expert supplier who prioritizes your results, offers proven-quality materials, and supports you at every stage.

Ready to elevate your next casting project? Your future—and your masterpiece—starts with the right sand.

Order from US Brass Cast Supplies today for exclusive offers, free technical support, and fast shipping direct to your door.

You bring the vision—we bring the results. Let's cast something great together.

Expert FAQs: Brass Casting Sand

Q1: What is brass casting sand, and why is it important?

Brass casting sand is a special blend of sand used to form molds for pouring molten brass. It determines the strength, accuracy, and finish of your final product. High-purity, stable sands reduce defects, improve surface quality, and guarantee dimensional precision.

Q2: How do I start sand casting brass at home?

You'll need a durable mold box, high-temperature brass casting sand, a foundry or propane furnace, protective gear, and brass ingots. Shape your sand mold, melt the brass, pour carefully, and let it cool. With basic training, most hobbyists cast small parts in under an hour.

Q3: What makes premium sand casting brass different from DIY blends?

Professional products offer higher purity, tighter grain-size control, and proven binder chemistry. This translates to fewer air pockets, better definition, and stronger castings. DIY blends often cause inconsistent results and more scrap.

Q4: Can I reuse brass casting sand?

Yes! Quality sand is designed for reuse. Just remove any debris and maintain moisture levels. With proper care, some blends last for dozens of cycles without dropping in quality.

Q5: What applications use sand casting brass most?

Popular applications include vintage auto parts, costume jewelry, musical instrument pieces, machine gears, decorative knobs, art sculptures, and more. Small-batch manufacturers and home workshops both rely on it.

Q6: What safety steps should I take when sand casting brass?

Always wear heat-resistant gloves, a full-face shield, and apron. Ensure good ventilation. Keep a fire extinguisher handy, and never pour near moisture. Education and caution are key!

Q7: Where can I buy trusted brass casting sand with technical support?

For the widest range and expert backing, buy from US Brass Cast Supplies. Our products are lab-tested, high-performance, and backed by real support. Shipping is fast and reliable across the United States.

(brass casting sand)

FAQS on brass casting sand

Q: What is brass casting sand used for?

A: Brass casting sand is used as a mold material to shape molten brass during the sand casting process. The sand holds the form of the desired object until the brass solidifies. This process is common for creating custom brass parts.Q: Can I do sand casting brass at home?

A: Yes, sand casting brass can be done at home with the proper safety equipment and materials. You'll need brass scrap, a furnace, casting sand, and molds. Always follow safety precautions due to high temperatures and molten metal.Q: What type of sand is best for brass casting?

A: Fine, high-quality foundry sand or green sand is ideal for brass casting. The sand needs to withstand high temperatures and retain shape well. Specialty brass casting sands are often available from foundry suppliers.Q: Is sand casting brass suitable for making small parts?

A: Yes, sand casting brass works well for both small and large parts. It's especially useful for prototypes and custom pieces. Precision details depend on the quality of the sand and mold.Q: How reusable is brass casting sand?

A: Brass casting sand can often be reused multiple times if kept clean and properly conditioned. However, over time it may degrade and require replacement. Removing impurities after each casting extends its usable life.-

Premium Green Sand for Casting | Durable & Cost-Effective Mold SolutionNewsJul.25,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Engineering, CustomizationNewsJul.22,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Engineering,Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025