Jan . 24, 2025 05:29

Back to list

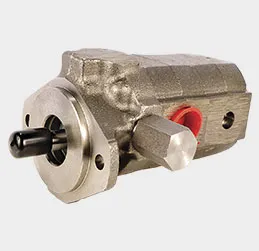

Oem Precision Castings Bearing

A352 steel is known for its exceptional properties tailored for demanding industrial applications, especially in environments where extreme temperatures and high pressures are prevalent. In order to leverage A352 steel to its fullest potential, it’s vital to understand both the technical expertise that underpins its application and the experiences shared by industries that utilize this material.

Real-world experiences further enhance the credibility and trustworthiness of A352 steel. Engineers who have worked extensively with this alloy report fewer failures and longer service life of components, translating to reduced downtime and maintenance costs. For instance, a global oil exploration company shared a case study where the implementation of A352 steel in their pipeline components reduced leakage incidents significantly, enhancing operational efficiency. To optimize your use of A352 steel, consider collaborating with experts who have specialized knowledge in steel fabrication and assembly. Their insights can guide material selection to suit specific environmental conditions and mechanical demands. It's also worthwhile to remain informed about the latest advancements in alloy development and fabrication technologies that could enhance the performance of A352 steel. When communicating the benefits of A352 steel to stakeholders, leverage the concepts of authority and trustworthiness by referencing industry case studies and standards compliance. This strategy not only positions your narrative within a factual framework but also reassures clients and partners of the material’s reliability and your commitment to quality. By focusing on expert-driven insights and proven industry experiences, the narrative around A352 steel can be both informative and persuasive, ensuring it stands out in the digital landscape. As industries continue to evolve, maintaining a commitment to quality and performance can solidify A352 steel's standing as a material of choice for challenging applications.

Real-world experiences further enhance the credibility and trustworthiness of A352 steel. Engineers who have worked extensively with this alloy report fewer failures and longer service life of components, translating to reduced downtime and maintenance costs. For instance, a global oil exploration company shared a case study where the implementation of A352 steel in their pipeline components reduced leakage incidents significantly, enhancing operational efficiency. To optimize your use of A352 steel, consider collaborating with experts who have specialized knowledge in steel fabrication and assembly. Their insights can guide material selection to suit specific environmental conditions and mechanical demands. It's also worthwhile to remain informed about the latest advancements in alloy development and fabrication technologies that could enhance the performance of A352 steel. When communicating the benefits of A352 steel to stakeholders, leverage the concepts of authority and trustworthiness by referencing industry case studies and standards compliance. This strategy not only positions your narrative within a factual framework but also reassures clients and partners of the material’s reliability and your commitment to quality. By focusing on expert-driven insights and proven industry experiences, the narrative around A352 steel can be both informative and persuasive, ensuring it stands out in the digital landscape. As industries continue to evolve, maintaining a commitment to quality and performance can solidify A352 steel's standing as a material of choice for challenging applications.

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES