лют . 20, 2025 02:16

Back to list

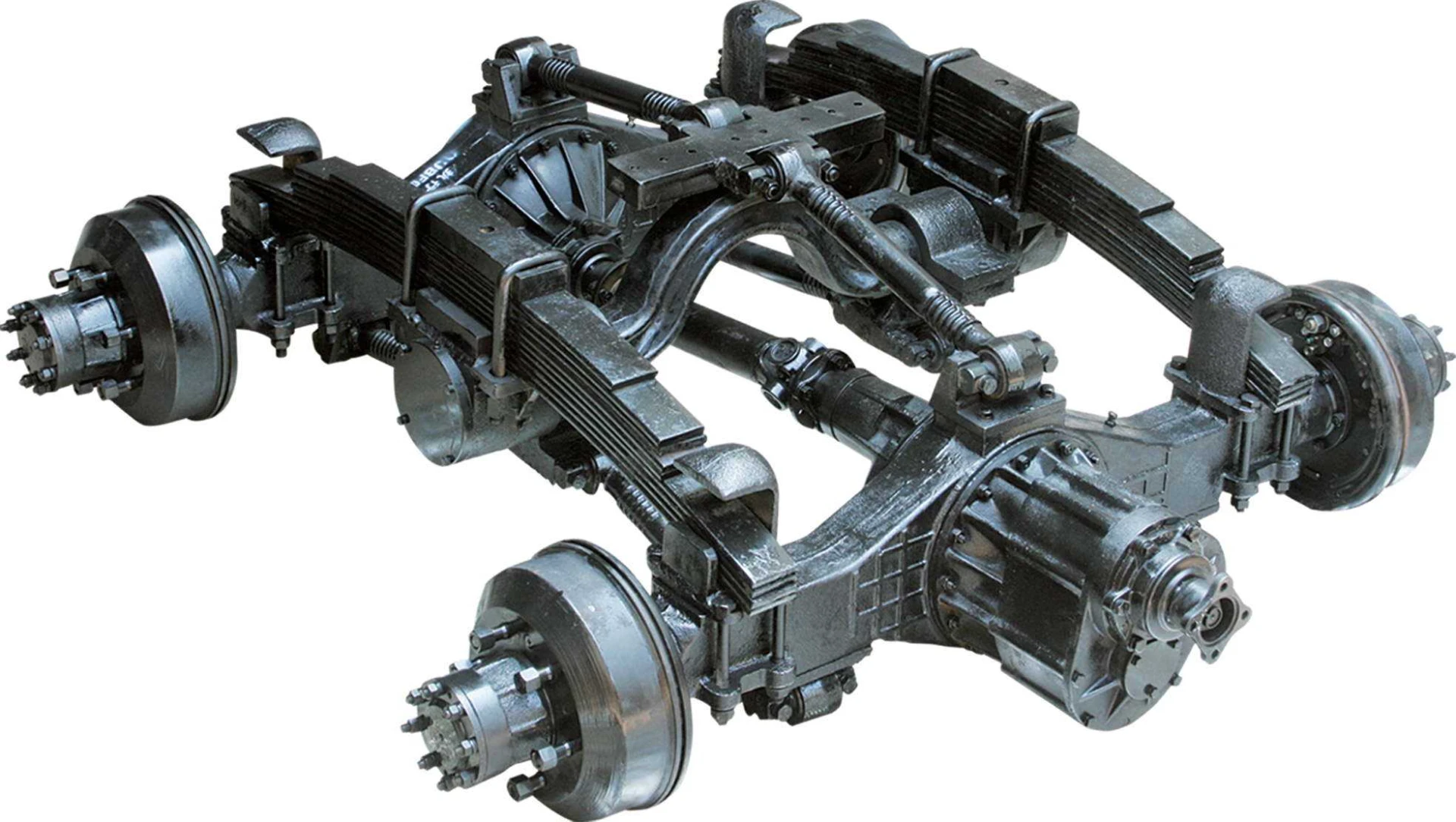

stamped steel parts

Stamped steel parts play a crucial role in various industries today, offering a perfect blend of durability, versatility, and cost-effectiveness. These components, made through the metal stamping process, are fundamental in applications ranging from automotive to home appliances and electronics. This article delves into the intricacies of stamped steel parts, highlighting their importance, production techniques, and real-world applications, while also showcasing the expertise and authority surrounding this essential manufacturing process.

A real-world example of stamped steel parts demonstrating expertise and reliability is in the automotive sector. These components are integral in the manufacturing of vehicles, from the body panels to engine parts. The precision and strength of stamped steel ensure the safety and performance of vehicles, underscoring their crucial role. Renowned automakers rely on such components to deliver reliable transportation, which further establishes the trustworthiness of stamped steel parts. In industries such as home appliances, stamped steel parts are invaluable. They not only contribute to the functional aspects of appliances but also enhance their aesthetic appeal. The consistent quality and finish provided by stamping ensure that appliance manufacturers can deliver products that meet consumer expectations in both style and durability. Consequently, stamped steel parts help maintain manufacturer reputation, building consumer trust in their products. Environmental considerations also underscore the expertise behind stamped steel parts production. Modern advancements have led to the use of recyclable materials in the stamping process, aligning with the global push toward sustainability. Using eco-friendly materials while ensuring the strength and reliability of stamped steel parts demonstrates a commitment to environmental responsibility within the industry. This aspect appeals to ethically-aware consumers and reinforces the authoritative stance manufacturers have within their markets. In conclusion, stamped steel parts are a cornerstone of various industries, embodying expertise, authority, and reliability. Through advanced manufacturing techniques, these components continue to meet the evolving needs of sectors such as automotive and home appliances. Their role in providing cost-effective, durable, and precision-engineered solutions is unmatched, making them indispensable. By ensuring environmental sustainability, manufacturers and consumers alike can place their trust in stamped steel parts, securing their relevance for future technological advancements.

A real-world example of stamped steel parts demonstrating expertise and reliability is in the automotive sector. These components are integral in the manufacturing of vehicles, from the body panels to engine parts. The precision and strength of stamped steel ensure the safety and performance of vehicles, underscoring their crucial role. Renowned automakers rely on such components to deliver reliable transportation, which further establishes the trustworthiness of stamped steel parts. In industries such as home appliances, stamped steel parts are invaluable. They not only contribute to the functional aspects of appliances but also enhance their aesthetic appeal. The consistent quality and finish provided by stamping ensure that appliance manufacturers can deliver products that meet consumer expectations in both style and durability. Consequently, stamped steel parts help maintain manufacturer reputation, building consumer trust in their products. Environmental considerations also underscore the expertise behind stamped steel parts production. Modern advancements have led to the use of recyclable materials in the stamping process, aligning with the global push toward sustainability. Using eco-friendly materials while ensuring the strength and reliability of stamped steel parts demonstrates a commitment to environmental responsibility within the industry. This aspect appeals to ethically-aware consumers and reinforces the authoritative stance manufacturers have within their markets. In conclusion, stamped steel parts are a cornerstone of various industries, embodying expertise, authority, and reliability. Through advanced manufacturing techniques, these components continue to meet the evolving needs of sectors such as automotive and home appliances. Their role in providing cost-effective, durable, and precision-engineered solutions is unmatched, making them indispensable. By ensuring environmental sustainability, manufacturers and consumers alike can place their trust in stamped steel parts, securing their relevance for future technological advancements.

Prev:

Next:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES