Exploring Components and Materials for Custom Rubber Stamp Production

Understanding Rubber Stamp Parts An Insight into Their Composition and Functionality

Rubber stamps have been integral to various industries for decades, serving multiple purposes ranging from office tasks to artistic expressions. At the core of their effectiveness and usability are the essential parts that make up a rubber stamp. Understanding these components helps in appreciating their functionality and aids in making informed choices when selecting or customizing stamps for specific needs.

1. Stamp Base

The stamp base is the foundation of any rubber stamp. It is typically made from durable materials like wood or plastic, providing stability and a comfortable grip for the user. The base must be sturdy enough to withstand repeated stamping without warping or breaking. Some modern stamps also feature ergonomic designs, enhancing user comfort and efficiency during use. The choice of base material affects not only aesthetics but also the longevity and functionality of the stamp.

2. Elastomer

Elastomers, commonly made from natural rubber or synthetic materials like photopolymer, form the heart of the rubber stamp. This material is specially formulated to hold ink and create clear impressions on surfaces when pressed down. The elastomer is often mounted onto the stamp base, and its quality significantly influences the clarity and detail of the stamped image. The rubber’s elasticity allows it to return to its original shape after pressure is applied, ensuring that the stamp can produce multiple impressions without losing its integrity.

3. Ink Pad

An ink pad is an essential accessory that provides the color and ink needed for stamping. These pads are typically filled with quick-drying, permanent ink that adheres well to various surfaces, including paper, cardboard, fabric, and plastic. The size and type of the ink pad can vary, with options available for different applications. Some ink pads are designed for specific ink types such as solvent-based or water-based inks, each producing unique results. Regular maintenance of ink pads is crucial; they should be kept clean to ensure that the ink flows uniformly and the impressions remain sharp.

4. Mounting Plate

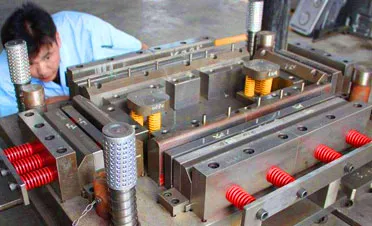

rubber stamp parts

In custom rubber stamps, a mounting plate is used to hold the elastomer firmly in place. It connects the stamp design with the base. Proper alignment is vital for ensuring that each impression is accurately placed, which is particularly important for business stamps that require precise lettering or logos. Mounting plates can be made from various materials, including acrylic or other durable composites, and come in different thicknesses depending on the design requirements.

5. Handle

The handle of a rubber stamp is designed for ease of use, allowing users to apply the necessary pressure to make a clear impression. Normally located at the top of the stamp, the handle can come in various designs, from simple, traditional styles to more modern and ergonomic forms. A good handle provides a firm grip and can significantly affect the stamping experience, especially during prolonged use.

6. Design Layer

The design layer, typically made from rubber or photopolymer, contains the actual artwork or text that will be reproduced when the stamp is pressed. This layer is often finely detailed to ensure that the images and letters are clear and accurate. The effectiveness of the design layer directly correlates with the quality of the stamp; high-resolution designs and precise manufacturing processes lead to better results.

7. Cleaning and Maintenance Parts

Proper care is essential to prolong the life of rubber stamps and maintain their effectiveness. Cleaning solutions, brushes, and cloths are often used to keep the elastomer clean and free from ink residue. Some stamp systems also incorporate removable components that simplify the maintenance process. Users should be aware of the appropriate cleaning methods for their specific stamp types to prevent damage.

Conclusion

Rubber stamps may seem simple, yet the synergy of their various parts—base, elastomer, ink pad, mounting plate, handle, design layer, and maintenance tools—makes them versatile tools indispensable in many environments. Understanding each component enhances users' ability to choose the right rubber stamps that fit their specific needs, ensuring that they produce high-quality impressions effortlessly. Whether for commercial use, crafting, or personal expression, knowing the parts of a rubber stamp is essential for maximizing its potential.

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025