студ . 21, 2025 02:00

Back to list

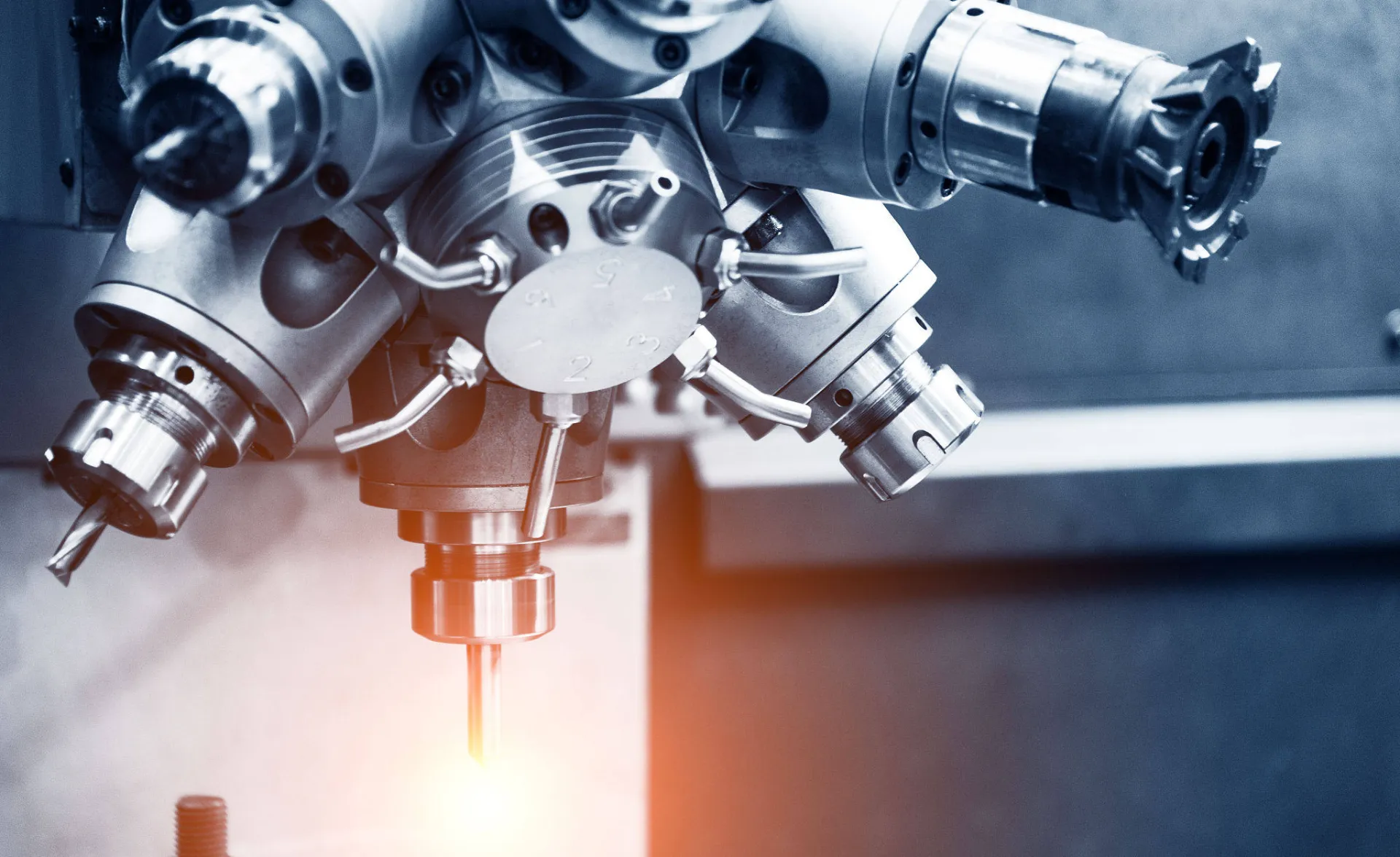

precision aluminum die casting

Precision aluminum die casting is revolutionizing the manufacturing landscape, offering unparalleled benefits for a range of industries from automotive to aerospace. This advanced process, which involves injecting molten aluminum into a mold to create complex and precise components, is celebrated for its ability to meet stringent tolerances while ensuring superior quality and cost-efficiency.

Trustworthiness in this context is built on the reliability and durability of the products manufactured through precision aluminum die casting. Industries reliant on this technology demand a high degree of traceability and verification at all production stages. By employing state-of-the-art non-destructive testing methods, manufacturers can guarantee the integrity of each component, instilling confidence in their clientele. Furthermore, sustainable practices in recycling and waste management related to die casting bolster trust, as companies emphasize their commitment to environmentally friendly manufacturing processes. The surge in demand for precision aluminum die casting is not merely a trend but a testament to its efficacy and value. The automotive industry, in particular, highlights numerous case studies where the integration of aluminum components has significantly enhanced vehicle performance and efficiency. In the electronics sector, the precision offered by die casting supports the miniaturization of devices while ensuring durability and heat dissipation – crucial factors in the ever-evolving consumer electronics market. As technology progresses, the role of precision aluminum die casting is expected to grow even more vital. Innovations in 3D printing, combined with traditional die casting, are pushing the boundaries of what's possible, enabling the production of parts that are lighter, more robust, and more complex than ever before. This convergence of technologies bodes well for sectors aiming to enhance their competitive edge through superior product offerings. Ultimately, the expertise accumulated by industry leaders and the success stories of their collaboration with precision aluminum die casting manufacturers form a strong foundation for future developments. This synergy promises continuous improvement and adaptation, ensuring that precision aluminum die casting remains an integral component of global manufacturing strategies.

Trustworthiness in this context is built on the reliability and durability of the products manufactured through precision aluminum die casting. Industries reliant on this technology demand a high degree of traceability and verification at all production stages. By employing state-of-the-art non-destructive testing methods, manufacturers can guarantee the integrity of each component, instilling confidence in their clientele. Furthermore, sustainable practices in recycling and waste management related to die casting bolster trust, as companies emphasize their commitment to environmentally friendly manufacturing processes. The surge in demand for precision aluminum die casting is not merely a trend but a testament to its efficacy and value. The automotive industry, in particular, highlights numerous case studies where the integration of aluminum components has significantly enhanced vehicle performance and efficiency. In the electronics sector, the precision offered by die casting supports the miniaturization of devices while ensuring durability and heat dissipation – crucial factors in the ever-evolving consumer electronics market. As technology progresses, the role of precision aluminum die casting is expected to grow even more vital. Innovations in 3D printing, combined with traditional die casting, are pushing the boundaries of what's possible, enabling the production of parts that are lighter, more robust, and more complex than ever before. This convergence of technologies bodes well for sectors aiming to enhance their competitive edge through superior product offerings. Ultimately, the expertise accumulated by industry leaders and the success stories of their collaboration with precision aluminum die casting manufacturers form a strong foundation for future developments. This synergy promises continuous improvement and adaptation, ensuring that precision aluminum die casting remains an integral component of global manufacturing strategies.

Prev:

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES