студ . 13, 2025 17:07

Back to list

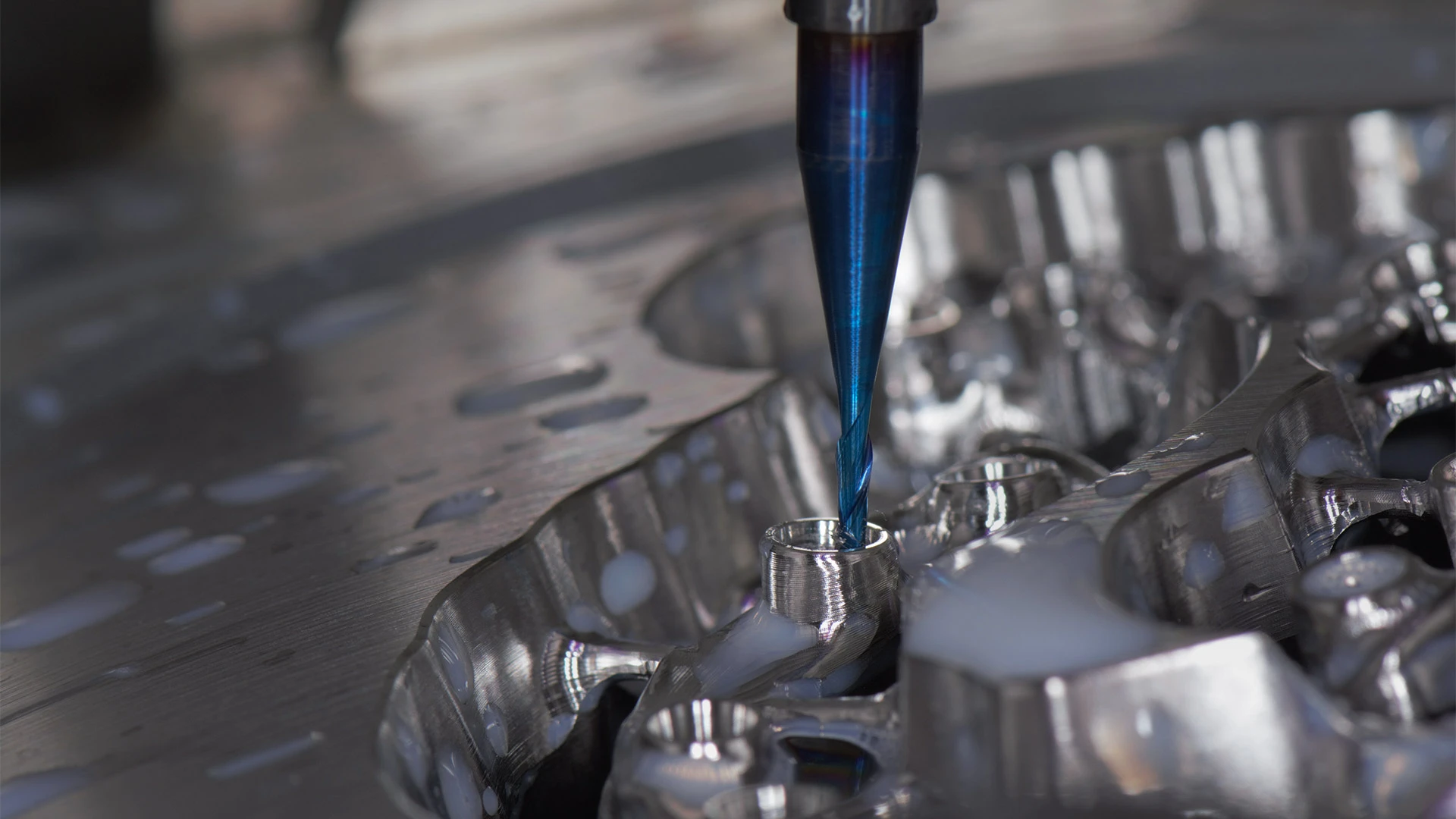

Oem Precision Castings Automotive

In the rapidly evolving world of automotive manufacturing, casting processes play a pivotal role in shaping the future of vehicle production. As a core component of automotive fabrication, casting involves pouring liquid metal into precisely crafted molds, allowing it to solidify and form intricate geometrical shapes. This process is essential in creating durable and reliable automotive components that require precision and strength, such as engine blocks, transmission housings, and suspension components.

Authoritativeness in the domain of automotive casting is further established by continual advancements fueled by innovation and research. Industry leaders and academic institutions collaborate to push the boundaries of what casting technologies can achieve. The development of smart factories and the integration of IoT in casting processes exemplify cutting-edge progressions that enhance monitoring and reduce waste. The implementation of these technologies not only magnifies the efficiency and productivity of casting operations but also fosters sustainable manufacturing practices by minimizing emissions and conserving resources. Trustworthiness is paramount in automotive casting given that it directly impacts vehicle safety and reliability. For manufacturers, adhering to stringent industry standards and certifications, such as ISO/TS 16949, is non-negotiable. These standards ensure that every component meets rigorous safety and quality benchmarks. Additionally, manufacturers with comprehensive quality assurance programs conduct rigorous testing and inspections at every stage of the casting process, from initial design through final production. This commitment to quality ensures that each automotive component performs reliably under the demanding conditions experienced on the road. In summary, the domain of automotive casting is a testament to the blend of skill, technology, and stringent quality standards that define modern manufacturing excellence. The continual evolution and enhancements in casting methodologies not only underline the importance of maintaining high standards in producing vital automotive components but also underscore the significance of innovation in driving the industry forward. As vehicles become more advanced, the role of casting will undoubtedly expand, showcasing the need for perpetuating expertise, authority, and trust in this critical field.

Authoritativeness in the domain of automotive casting is further established by continual advancements fueled by innovation and research. Industry leaders and academic institutions collaborate to push the boundaries of what casting technologies can achieve. The development of smart factories and the integration of IoT in casting processes exemplify cutting-edge progressions that enhance monitoring and reduce waste. The implementation of these technologies not only magnifies the efficiency and productivity of casting operations but also fosters sustainable manufacturing practices by minimizing emissions and conserving resources. Trustworthiness is paramount in automotive casting given that it directly impacts vehicle safety and reliability. For manufacturers, adhering to stringent industry standards and certifications, such as ISO/TS 16949, is non-negotiable. These standards ensure that every component meets rigorous safety and quality benchmarks. Additionally, manufacturers with comprehensive quality assurance programs conduct rigorous testing and inspections at every stage of the casting process, from initial design through final production. This commitment to quality ensures that each automotive component performs reliably under the demanding conditions experienced on the road. In summary, the domain of automotive casting is a testament to the blend of skill, technology, and stringent quality standards that define modern manufacturing excellence. The continual evolution and enhancements in casting methodologies not only underline the importance of maintaining high standards in producing vital automotive components but also underscore the significance of innovation in driving the industry forward. As vehicles become more advanced, the role of casting will undoubtedly expand, showcasing the need for perpetuating expertise, authority, and trust in this critical field.

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

PRODUCTS CATEGORIES