студ . 10, 2025 09:47

Back to list

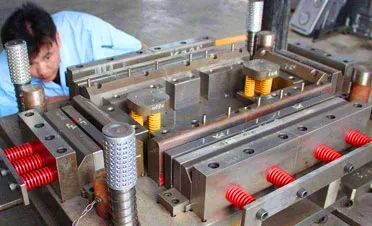

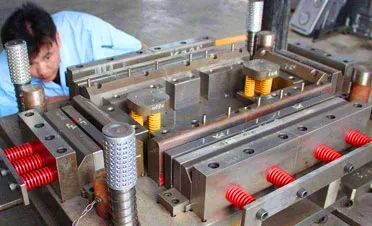

Oem Die Casting Piston Fittings

Choosing the right gravity die casting supplier can significantly impact the quality of your products and the efficiency of your production processes. Gravity die casting, a process where molten metal is poured into a metal mold under gravity alone, is renowned for producing high-quality, intricate components with excellent mechanical properties. However, achieving these results depends largely on the expertise, experience, and credibility of your chosen supplier.

Trustworthiness, an essential pillar of any business relationship, is built upon transparent communication and dependable delivery. A reliable gravity die casting supplier commits to clear timelines and consistently delivers products as per the promised specifications. They also maintain open lines of communication throughout the project lifecycle, providing regular updates and promptly addressing any concerns. This transparency helps to forge strong, long-lasting partnerships between the supplier and their clients. Additionally, a credible supplier will offer comprehensive post-production support. This includes advice on maintenance, troubleshooting, and the potential for part redesign to optimize production efficiency further. Such support ensures that clients can maximize the lifespan and performance of their products, leading to a better return on investment. In conclusion, selecting a gravity die casting supplier requires a careful balance of experience, expertise, authoritativeness, and trustworthiness. By focusing on these core indicators, companies can ensure they choose a partner who will not only meet their immediate casting needs but also contribute to their broader strategic objectives. The right supplier offers more than just parts – they deliver peace of mind, knowing that your products are crafted with precision, care, and a commitment to excellence.

Trustworthiness, an essential pillar of any business relationship, is built upon transparent communication and dependable delivery. A reliable gravity die casting supplier commits to clear timelines and consistently delivers products as per the promised specifications. They also maintain open lines of communication throughout the project lifecycle, providing regular updates and promptly addressing any concerns. This transparency helps to forge strong, long-lasting partnerships between the supplier and their clients. Additionally, a credible supplier will offer comprehensive post-production support. This includes advice on maintenance, troubleshooting, and the potential for part redesign to optimize production efficiency further. Such support ensures that clients can maximize the lifespan and performance of their products, leading to a better return on investment. In conclusion, selecting a gravity die casting supplier requires a careful balance of experience, expertise, authoritativeness, and trustworthiness. By focusing on these core indicators, companies can ensure they choose a partner who will not only meet their immediate casting needs but also contribute to their broader strategic objectives. The right supplier offers more than just parts – they deliver peace of mind, knowing that your products are crafted with precision, care, and a commitment to excellence.

Latest news

-

Precision Aluminum Casting Parts Manufacturer High-Quality Investment & Die Casting SolutionsNewsJul.05,2025

-

Investment Precision Casting Share Price & Cost Guide - Competitive Sand & Aluminium Die Casting PricesNewsJul.05,2025

-

Technocrats Die Casting Solutions – Precision Hot & Cold Chamber Die Casting ExpertsNewsJun.24,2025

-

Precision Glass Machining Solutions Sand Casting Glass & Abrasive Water Jet Machining ExpertsNewsJun.24,2025

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

PRODUCTS CATEGORIES