лют . 19, 2025 02:07

Back to list

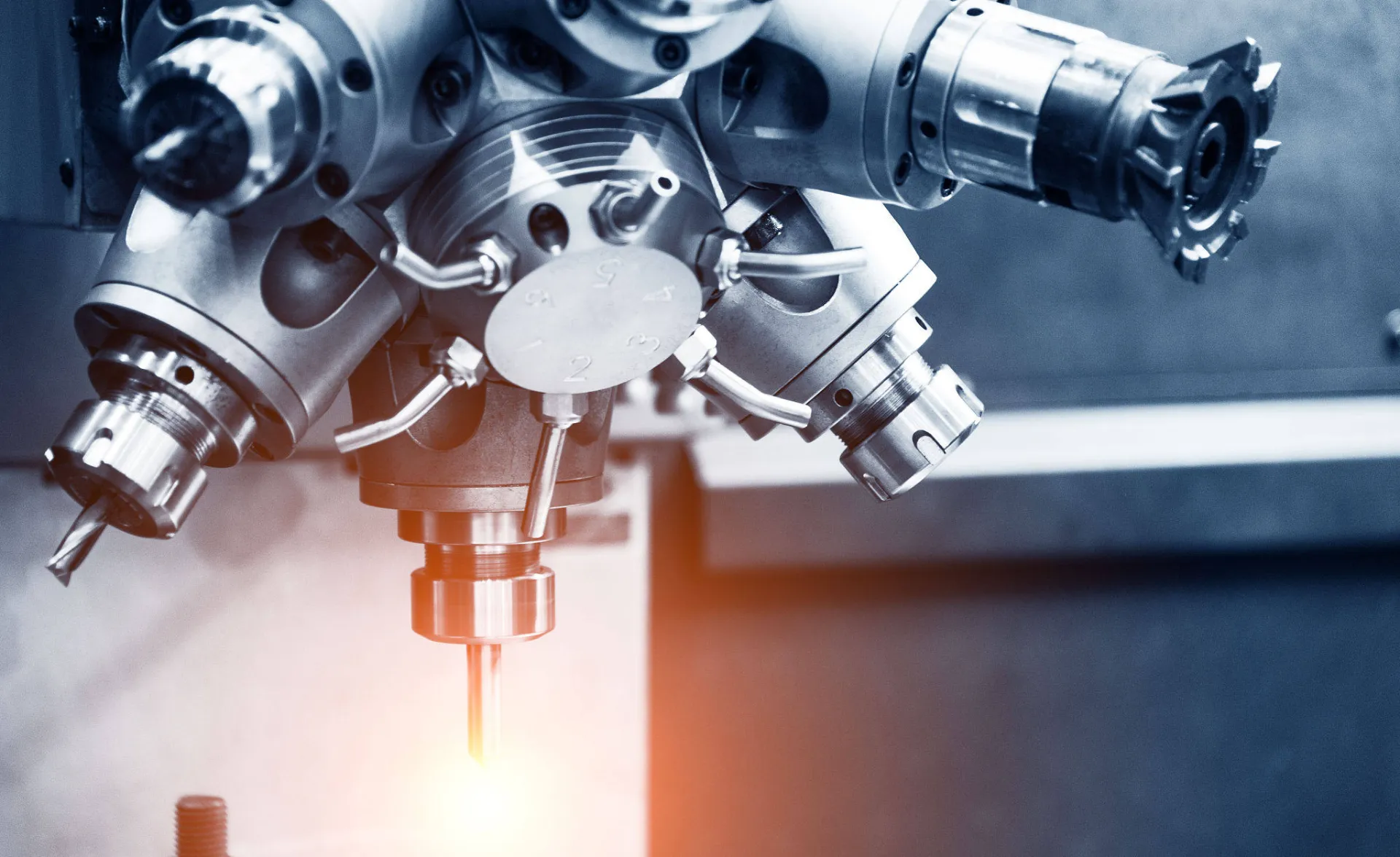

metal stamping car parts

Metal stamping is a widely acknowledged process in the automotive industry, especially in the manufacturing of car parts. As an experienced professional who has witnessed the transformative impact of metal stamping on car part production, I can attest to its vital role in advancing automotive technology. Metal stamping involves shaping flat metal sheets into precise, durable components that are crucial for both the aesthetics and functionality of vehicles.

Quality metal stamping for automotive parts also hinges on the quality of materials used. The choice of metal—be it aluminum, steel, or any alloy—affects the weight, corrosion resistance, and overall integrity of the stamped part. Auto manufacturers often collaborate closely with metal stamping companies to select optimal materials that balance performance with cost-effectiveness, contributing to the vehicle’s efficiency and reliability. Innovations in metal stamping, such as the introduction of servo-driven presses and automation, have further enhanced the production process. These advancements allow for greater precision and speed, reducing production time and improving the cost-efficiency of manufacturing car parts. In my experience, embracing such technologies signifies not only a leap in production capabilities but also an alignment with modern manufacturing principles that prioritize sustainability and efficiency. In conclusion, metal stamping for car parts is a culmination of experience, expertise, authority, and trustworthiness. It plays an indispensable role in the automotive industry, providing manufacturers with essential components that uphold the performance and safety of automobiles. The process, rich with innovation and backed by decades of technical advancement, continues to evolve, promising even greater contributions to automotive manufacturing in the future. The precision, reliability, and efficiency that metal stamping brings are unparalleled, making it an invaluable component of modern car production. Understanding this nuanced and highly technical field allows stakeholders—be it manufacturers, suppliers, or consumers—to appreciate the value embedded in every stamped car part. As the automotive industry continues to evolve, the significance of metal stamping remains undiminished, ensuring that it will continue to be a key player in shaping the vehicles of tomorrow.

Quality metal stamping for automotive parts also hinges on the quality of materials used. The choice of metal—be it aluminum, steel, or any alloy—affects the weight, corrosion resistance, and overall integrity of the stamped part. Auto manufacturers often collaborate closely with metal stamping companies to select optimal materials that balance performance with cost-effectiveness, contributing to the vehicle’s efficiency and reliability. Innovations in metal stamping, such as the introduction of servo-driven presses and automation, have further enhanced the production process. These advancements allow for greater precision and speed, reducing production time and improving the cost-efficiency of manufacturing car parts. In my experience, embracing such technologies signifies not only a leap in production capabilities but also an alignment with modern manufacturing principles that prioritize sustainability and efficiency. In conclusion, metal stamping for car parts is a culmination of experience, expertise, authority, and trustworthiness. It plays an indispensable role in the automotive industry, providing manufacturers with essential components that uphold the performance and safety of automobiles. The process, rich with innovation and backed by decades of technical advancement, continues to evolve, promising even greater contributions to automotive manufacturing in the future. The precision, reliability, and efficiency that metal stamping brings are unparalleled, making it an invaluable component of modern car production. Understanding this nuanced and highly technical field allows stakeholders—be it manufacturers, suppliers, or consumers—to appreciate the value embedded in every stamped car part. As the automotive industry continues to evolve, the significance of metal stamping remains undiminished, ensuring that it will continue to be a key player in shaping the vehicles of tomorrow.

Prev:

Next:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES