студ . 20, 2025 15:12

Back to list

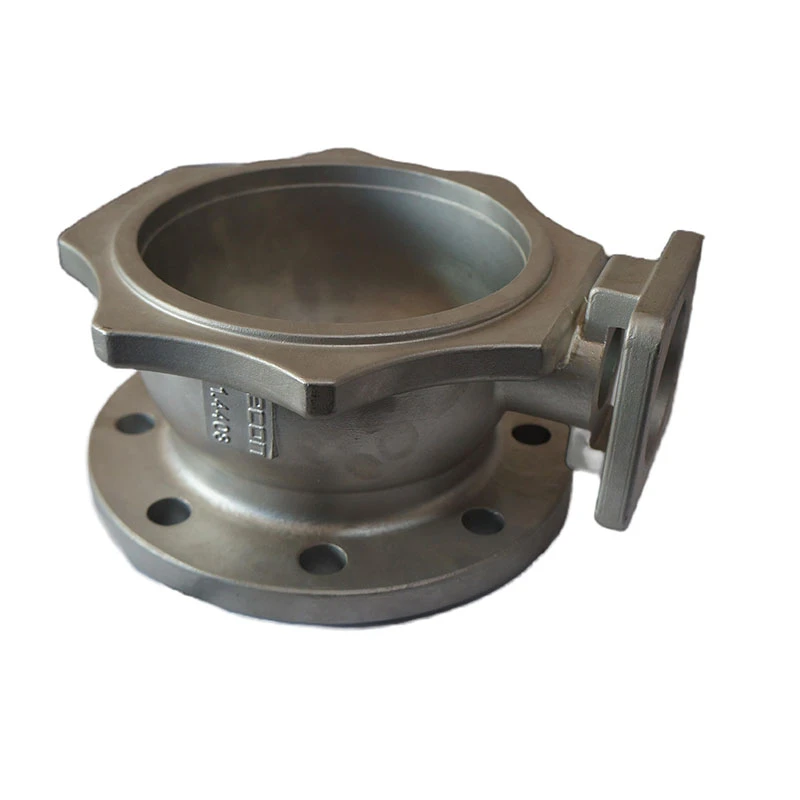

Oem Precision Castings Impeller

Investment precision castings represent a pivotal aspect of modern manufacturing, offering indispensable solutions for industries that require intricate and durable metal parts. With ever-increasing demands for high-quality, cost-effective products, precision castings have emerged as a cornerstone of industrial applications.

Credibility in precision casting is often associated with the foundries' expertise, where state-of-the-art technology and skilled craftsmanship converge. Partnering with a foundry that offers robust quality assurance programs ensures the reliability of the end product. This includes rigorous inspection techniques like X-ray, ultrasonic testing, and metallurgical analysis to guarantee the castings meet stringent industry standards. For businesses seeking to incorporate investment precision castings into their production lines, selecting a partner with a proven track record is paramount. Considerations should include the foundry’s capacity for innovation, its adherence to international quality standards, and its commitment to sustainability practices. A reputable foundry will assist not just in manufacturing but also in the design and materials selection processes, optimizing each stage to ensure peak performance and cost efficiency. Furthermore, embracing modern advancements such as 3D printing for pattern creation can dramatically accelerate the pre-production phase, offering unparalleled flexibility and prompt prototyping capabilities. With rapid prototyping, businesses can conduct real-world testing and iterations more efficiently, minimizing time-to-market for new products. Investment precision castings hold the promise of revolutionizing production processes with their precision, adaptability, and economic benefits. They allow businesses to stay at the forefront of technology while maintaining competitiveness in their respective fields. As global industries continue to seek sustainable and advanced manufacturing solutions, the role of precision castings is set to expand, reinforcing their importance in driving innovation and excellence. The choice of a seasoned partner in this endeavor ultimately influences the product's success, underscoring the integral relationship between expertise and production quality in the realm of precision castings.

Credibility in precision casting is often associated with the foundries' expertise, where state-of-the-art technology and skilled craftsmanship converge. Partnering with a foundry that offers robust quality assurance programs ensures the reliability of the end product. This includes rigorous inspection techniques like X-ray, ultrasonic testing, and metallurgical analysis to guarantee the castings meet stringent industry standards. For businesses seeking to incorporate investment precision castings into their production lines, selecting a partner with a proven track record is paramount. Considerations should include the foundry’s capacity for innovation, its adherence to international quality standards, and its commitment to sustainability practices. A reputable foundry will assist not just in manufacturing but also in the design and materials selection processes, optimizing each stage to ensure peak performance and cost efficiency. Furthermore, embracing modern advancements such as 3D printing for pattern creation can dramatically accelerate the pre-production phase, offering unparalleled flexibility and prompt prototyping capabilities. With rapid prototyping, businesses can conduct real-world testing and iterations more efficiently, minimizing time-to-market for new products. Investment precision castings hold the promise of revolutionizing production processes with their precision, adaptability, and economic benefits. They allow businesses to stay at the forefront of technology while maintaining competitiveness in their respective fields. As global industries continue to seek sustainable and advanced manufacturing solutions, the role of precision castings is set to expand, reinforcing their importance in driving innovation and excellence. The choice of a seasoned partner in this endeavor ultimately influences the product's success, underscoring the integral relationship between expertise and production quality in the realm of precision castings.

Prev:

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES