лют . 03, 2025 03:05

Back to list

green sand vs dry sand casting

Home sand casting has surged in popularity as an accessible means of metalworking for hobbyists and small-scale artisans. Offering a practical way to craft bespoke metal pieces from the comfort of one’s home, it harnesses age-old techniques repurposed with modern insights and materials. This article explores the nuanced processes of home sand casting, delving into the necessity for meticulous preparation, the expertise required, and the tangible results one can achieve by mastering this intricate craft.

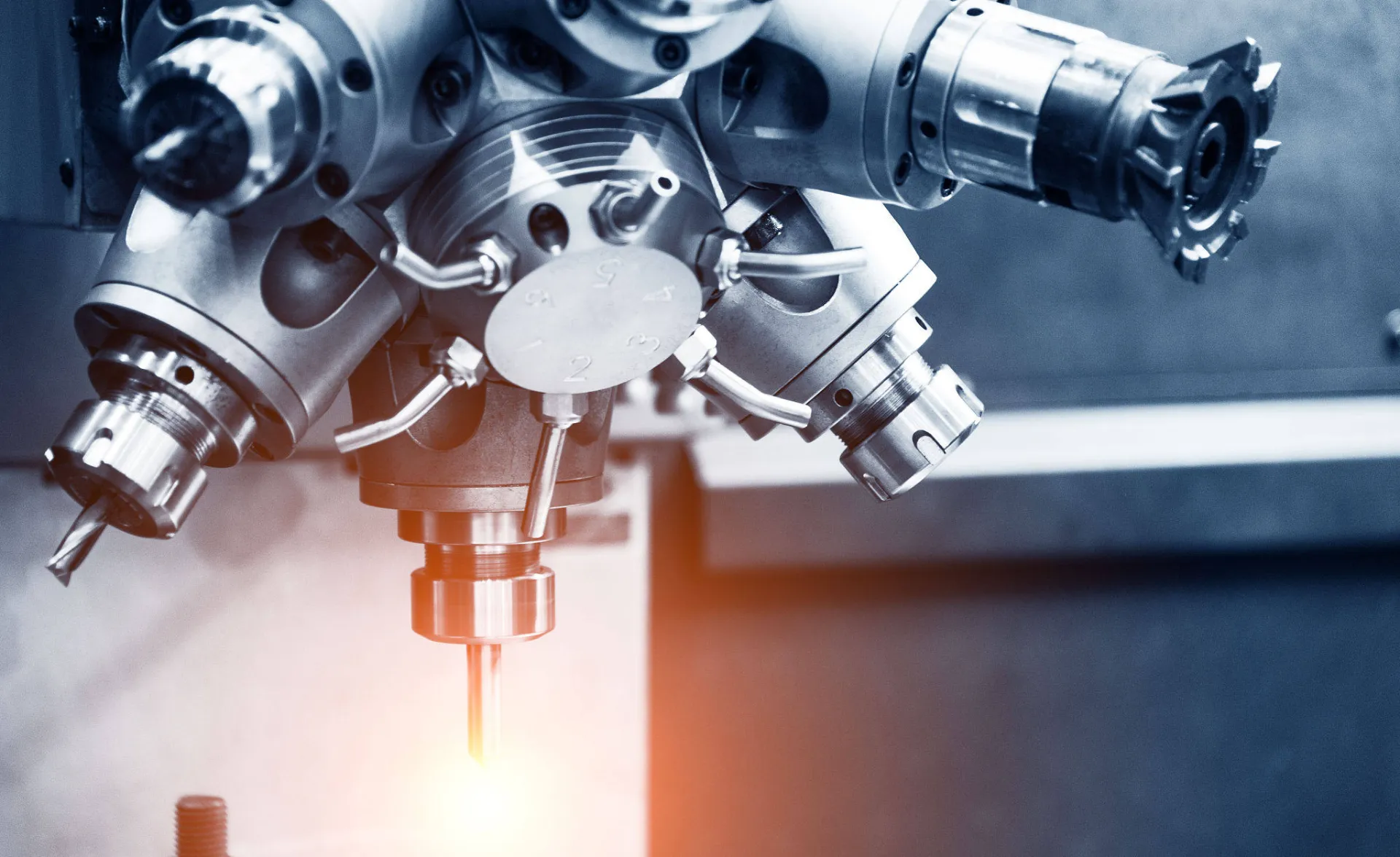

Post-casting processes enhance the authority and trustworthiness of your creations. After extraction from the sand mold, the metalwork often requires finishing—trimming or sanding any rough edges, followed by polishing to achieve a desired finish. Expertise in various finishing techniques enables the crafting of pieces that not only hold structural integrity but also aesthetic appeal. Leveraging tools like files, dremels, or even small CNC machines can elevate your work, distinguishing it from more rudimentary attempts. The authority of any sand caster lies in their understanding of metallurgy and the properties of various metals. Each metal, from aluminum to bronze, behaves differently under heat and pressure, influencing factors like melting point, flow characteristics, and shrinkage rates. The trusted sand caster builds this knowledge over time, referencing community resources and literature to expand their understanding and refine their technique. Home sand casting, when approached with a commitment to expertise and an eye for detail, leads to the creation of distinctive, high-quality metal objects that are both functional and artistic. This craft enables self-expression through diverse applications—from jewelry and tools to decorative pieces and bespoke hardware components. Overall, establishing trustworthiness in sand casting involves a mix of consistent practice, continuous learning, and adherence to industry and safety standards. Engaging with communities of fellow sand casters, sharing insights and experiences, can accelerate one’s journey from novice to expert. By fostering an environment of knowledge sharing and support, the craft not only sustains itself but also evolves, embracing new ideas and innovations. Ultimately, home sand casting is more than just a hobby; it is an art-form steeped in tradition, revitalized by those who dare to innovate and create. Through dedication and the honing of skill, one can achieve a remarkable symbiosis of creativity and technical precision—a testament to the enduring allure of working with metals.

Post-casting processes enhance the authority and trustworthiness of your creations. After extraction from the sand mold, the metalwork often requires finishing—trimming or sanding any rough edges, followed by polishing to achieve a desired finish. Expertise in various finishing techniques enables the crafting of pieces that not only hold structural integrity but also aesthetic appeal. Leveraging tools like files, dremels, or even small CNC machines can elevate your work, distinguishing it from more rudimentary attempts. The authority of any sand caster lies in their understanding of metallurgy and the properties of various metals. Each metal, from aluminum to bronze, behaves differently under heat and pressure, influencing factors like melting point, flow characteristics, and shrinkage rates. The trusted sand caster builds this knowledge over time, referencing community resources and literature to expand their understanding and refine their technique. Home sand casting, when approached with a commitment to expertise and an eye for detail, leads to the creation of distinctive, high-quality metal objects that are both functional and artistic. This craft enables self-expression through diverse applications—from jewelry and tools to decorative pieces and bespoke hardware components. Overall, establishing trustworthiness in sand casting involves a mix of consistent practice, continuous learning, and adherence to industry and safety standards. Engaging with communities of fellow sand casters, sharing insights and experiences, can accelerate one’s journey from novice to expert. By fostering an environment of knowledge sharing and support, the craft not only sustains itself but also evolves, embracing new ideas and innovations. Ultimately, home sand casting is more than just a hobby; it is an art-form steeped in tradition, revitalized by those who dare to innovate and create. Through dedication and the honing of skill, one can achieve a remarkable symbiosis of creativity and technical precision—a testament to the enduring allure of working with metals.

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Fluid Control & Custom CastingNewsAug.08,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Customization&Quality AssuranceNewsAug.08,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.08,2025

-

Precision Aluminium Die Casting Companies - Custom SolutionsNewsAug.08,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering, Industrial Fluid ControlNewsAug.08,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

PRODUCTS CATEGORIES