сак . 03, 2025 13:01

Back to list

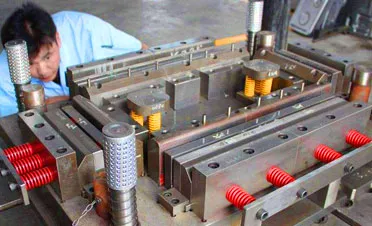

custom precision metal stamping parts

Custom precision metal stamping parts play a pivotal role in various industries, offering unparalleled accuracy and bespoke solutions tailored to specific requirements. These parts are manufactured using advanced technologies that ensure they meet the precise specifications needed for intricate applications. With the demand for precision engineering on the rise, it's essential to understand the advantages and processes that underpin the creation of these critical components.

Authoritativeness in this domain is demonstrated through adherence to strict industry standards and certifications. Reputable manufacturers often obtain ISO 9001 certification, highlighting their commitment to quality management principles. This certification ensures that every component produced meets high international quality and consistency standards. Additionally, compliance with industry-specific standards reinforces trust among clients, assuring them that their parts will perform reliably under all conditions. Trustworthiness is further enhanced by the transparency and collaboration between manufacturers and clients. Custom precision metal stamping manufacturers often invite clients to participate in the design and testing processes. This collaborative approach ensures that the final product not only meets precise specifications but also embodies the innovation and insight provided by both parties. By engaging clients throughout the production phase, manufacturers demonstrate their commitment to quality and satisfaction, which is vital for building long-term relationships. In the landscape of manufacturing, custom precision metal stamping parts are not merely products but solutions that propel industries forward. They embody the synthesis of experience, expertise, authoritativeness, and trustworthiness—the pillars upon which successful industrial applications are built. As technology progresses, so too will the methods and capabilities of precision metal stamping, continuing to offer unparalleled solutions for complex engineering challenges. The commitment to innovation and quality in producing precision metal stamping parts is evident, and it provides a tangible advantage to those who adopt these technologies. This dedication to advancement not only enhances operational efficiency but also positions businesses at the forefront of their respective industries, equipped with the components capable of meeting tomorrow's challenges.

Authoritativeness in this domain is demonstrated through adherence to strict industry standards and certifications. Reputable manufacturers often obtain ISO 9001 certification, highlighting their commitment to quality management principles. This certification ensures that every component produced meets high international quality and consistency standards. Additionally, compliance with industry-specific standards reinforces trust among clients, assuring them that their parts will perform reliably under all conditions. Trustworthiness is further enhanced by the transparency and collaboration between manufacturers and clients. Custom precision metal stamping manufacturers often invite clients to participate in the design and testing processes. This collaborative approach ensures that the final product not only meets precise specifications but also embodies the innovation and insight provided by both parties. By engaging clients throughout the production phase, manufacturers demonstrate their commitment to quality and satisfaction, which is vital for building long-term relationships. In the landscape of manufacturing, custom precision metal stamping parts are not merely products but solutions that propel industries forward. They embody the synthesis of experience, expertise, authoritativeness, and trustworthiness—the pillars upon which successful industrial applications are built. As technology progresses, so too will the methods and capabilities of precision metal stamping, continuing to offer unparalleled solutions for complex engineering challenges. The commitment to innovation and quality in producing precision metal stamping parts is evident, and it provides a tangible advantage to those who adopt these technologies. This dedication to advancement not only enhances operational efficiency but also positions businesses at the forefront of their respective industries, equipped with the components capable of meeting tomorrow's challenges.

Next:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES