High-Quality Custom Metal Stamping Dies for Precision Manufacturing Solutions

Custom Metal Stamping Dies Enhancing Precision and Efficiency in Metal Fabrication

In the world of manufacturing, efficiency and precision are paramount. One area where these concepts take center stage is in the development and use of custom metal stamping dies. These specialized tools play a vital role in the metal fabrication industry, enabling manufacturers to produce high-quality components that meet specific design requirements.

What Are Custom Metal Stamping Dies?

Custom metal stamping dies are tools designed to shape and cut metal sheets into precise forms and sizes. They are utilized in stamping processes, where metal sheets are fed into a press, and the dies impart their shape onto the material. This process can create various components, from simple washers to complex automotive parts. The customization of these dies allows manufacturers to achieve unique designs tailored to their product specifications, leading to improved functionality and aesthetics.

Benefits of Custom Metal Stamping Dies

1. Precision Engineering Custom dies are designed to strict specifications, ensuring that every part produced meets the required tolerances. This precision is crucial in industries such as aerospace and automotive, where even minor discrepancies can lead to significant operational issues.

2. Cost-effectiveness While the initial investment in custom dies can be high, the long-term savings are often worth it. Automated stamping processes using custom dies can drastically reduce labor costs and increase production rates. This efficiency translates to lower manufacturing costs per unit.

3. Scalability Custom metal stamping allows manufacturers to produce large volumes of parts quickly and consistently. This scalability is particularly important in industries with high demand, enabling companies to respond rapidly to market needs without sacrificing quality.

4. Material Versatility Custom stamping dies can work with various materials, including aluminum, steel, and brass. This versatility means manufacturers can choose materials that best suit their application, balancing factors like strength, weight, and cost.

custom metal stamping die

5. Complex Designs The ability to create complex shapes and features with custom dies means that manufacturers can innovate and differentiate their products in a competitive market. Custom dies can incorporate intricate designs that might be challenging or impossible to achieve through other manufacturing methods.

The Process of Designing Custom Metal Stamping Dies

Creating custom metal stamping dies involves several steps

1. Requirement Analysis Understanding the specific needs of the manufacturing process is critical. This includes determining the materials to be used, the desired production volume, and the functional requirements of the final product.

2. Design and Prototyping Once the requirements are established, engineers use CAD software to design the die. This digital model allows for visualization and modifications before creating a physical prototype, ensuring that any design flaws are addressed early in the process.

3. Manufacturing the Die After finalizing the design, the die is manufactured using precise machining techniques. This step requires skilled technicians and advanced equipment to ensure the die meets the desired specifications.

4. Testing and Iteration Before full-scale production can commence, the die undergoes rigorous testing. This phase is crucial to identify any issues and make necessary adjustments, ensuring that the die performs optimally when used in the stamping process.

Conclusion

Custom metal stamping dies are indispensable tools in the manufacturing industry, driving efficiency, cost-effectiveness, and precision. By investing in high-quality custom dies, manufacturers can enhance their production capabilities, meet increasing demand, and stay competitive in a rapidly evolving market. As technology continues to advance, the future of custom metal stamping dies looks promising, with the potential for even greater innovations in design and functionality.

-

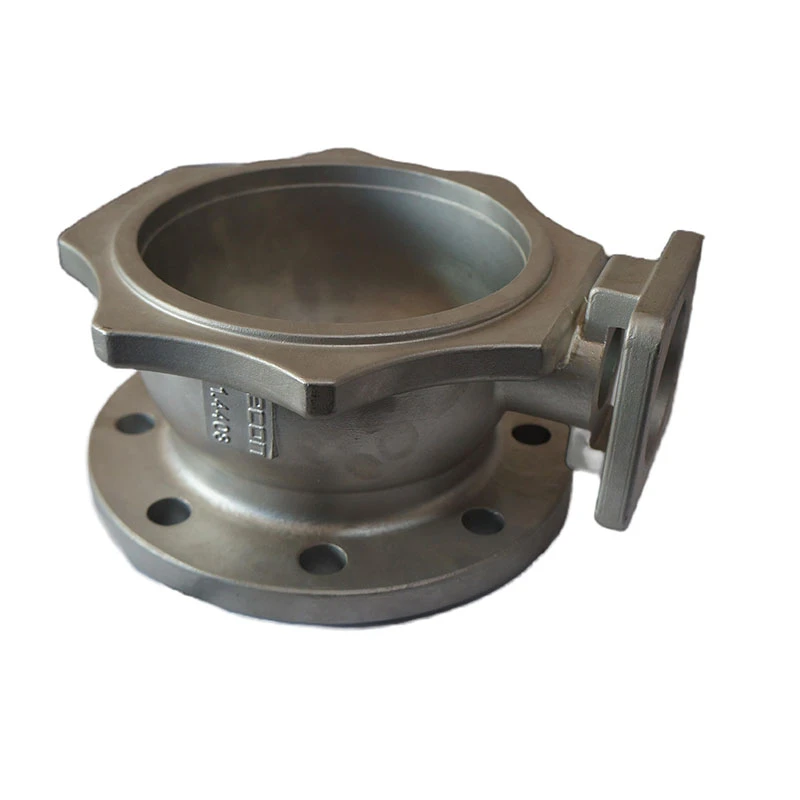

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025