China Supply High End Metal Stamping Parts Sino - Precision Manufacturing Factory

- Introduction to China supply high end metal stamping parts sino market

- Technological Advancements Elevating Performance Standards

- Comparative Assessment of Leading Manufacturers

- Customization Capabilities Driving Client Satisfaction

- Application Scenarios and Success Stories

- Quality Assurance, Certifications, and International Reach

- Conclusion: Why China supply high end metal stamping parts sino is the Optimal Choice

(china supply high end metal stamping parts sino)

Introduction to China supply high end metal stamping parts sino Market

The global demand for precision-engineered metal components has sharply accelerated over the past decade, powered by sectors such as automotive, electronics, medical devices, and energy infrastructure. Among the key global hubs, China supply high end metal stamping parts sino sector stands out due to its robust manufacturing ecosystem, investment in advanced machinery, and highly developed supply chains. The market size for metal stamping in China is estimated to reach USD 45 billion in 2024, growing at an annual rate of 7.5% since 2019 (Statista). This growth is fueled by stringent quality expectations in end-user industries, requiring manufacturers to deliver consistent tolerances of up to ±0.01 mm and complex shapes across large production volumes.

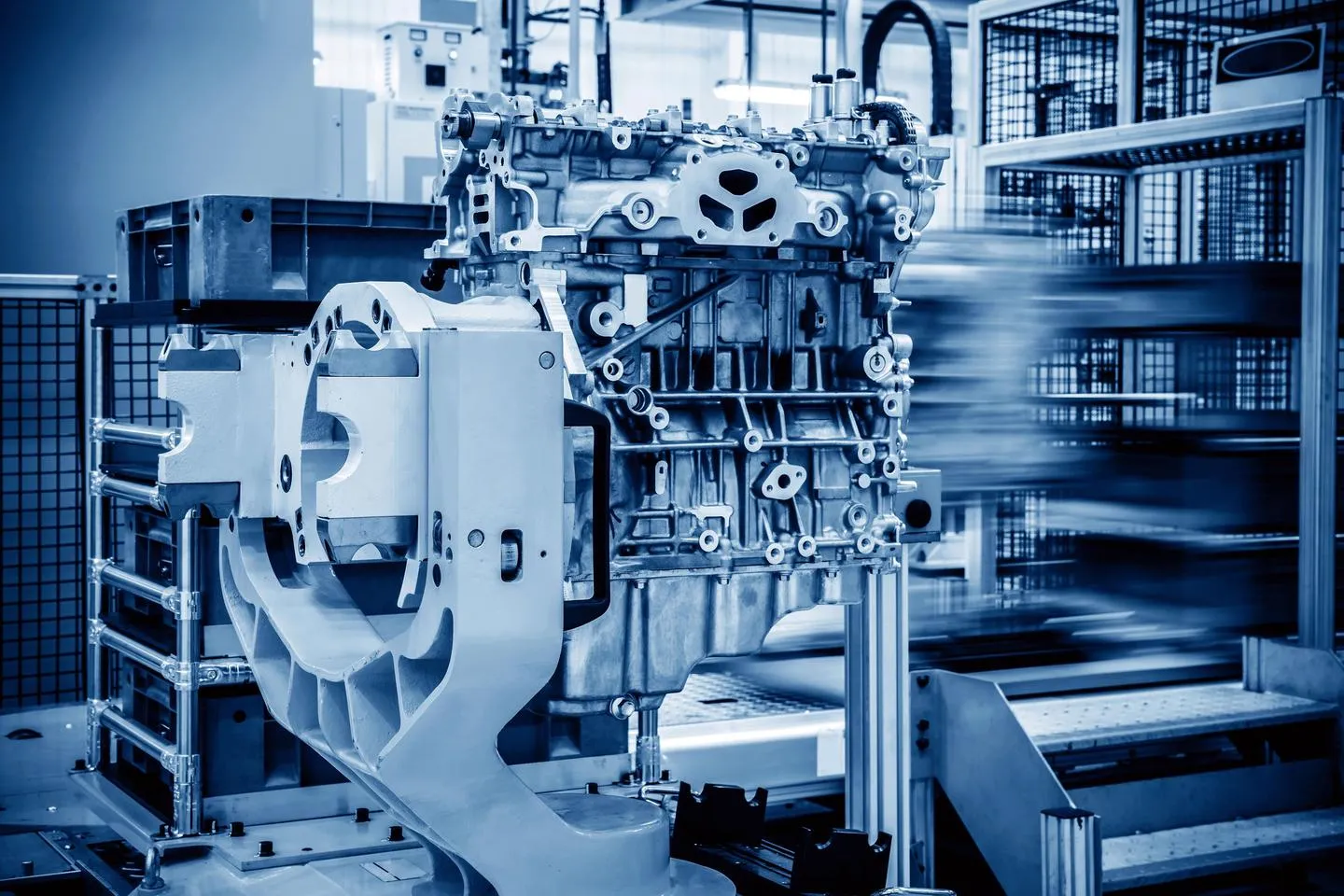

Technological Advancements Elevating Performance Standards

One of the core strengths of China's high-end metal stamping sector is adoption of state-of-the-art technologies such as servo-driven presses, in-die sensing, and automated guided vehicles (AGVs). These advancements enhance process reliability and efficiency, reducing waste rates by up to 30% compared to conventional presses. For instance, the integration of Computer-Aided Design/Manufacturing (CAD/CAM) platforms has streamlined product development cycles, allowing project turnaround in as little as 10 to 14 days for prototyping.

Furthermore, factories specializing in high-end china metal stamping parts sino utilize progressive die technology to form intricate geometries in a single, continuous operation. This leads to superior repeatability and surface finish, as well as lower energy consumption per part produced. According to industry data, utilization of servo technology can decrease stamping force variations by 25%, translating to longer tool life and lower maintenance costs.

Comparative Assessment of Leading Manufacturers

When evaluating leading high-end china metal stamping parts sino factories, it is crucial to consider aspects such as equipment fleet, production capacity, inspection capabilities, and pricing. The table below summarizes key differentiators for three prominent factories:

| Manufacturer | Annual Output (Million pcs) | Key Machinery | Certifications | Defect Rate (%) | Lead Time (days) | OEM/ODM Services |

|---|---|---|---|---|---|---|

| Factory A | 180 | Servo Presses, 3D Laser Cutting | IATF 16949, ISO 9001 | 0.08 | 14–21 | Yes |

| Factory B | 130 | Hydraulic Presses, Robotic Welding | ISO 14001, ISO 9001 | 0.12 | 18–25 | Yes |

| Factory C | 150 | Progressive Dies, CNC Machining | IATF 16949, ISO 9001 | 0.05 | 12–20 | Yes |

Notably, Factory A and Factory C deliver lower defect rates and faster lead times, reflecting their commitment to rigorous quality assurance and modern equipment scale. The ability to handle both OEM and ODM projects denotes adaptability in meeting varied client requirements.

Customization Capabilities Driving Client Satisfaction

In today’s market, flexibility of specification and tailor-made solutions are paramount. High-end china metal stamping parts sino factories exceed in offering engineering support from concept ideation through to mass production. Capabilities encompass:

- Material selection consultation, including stainless steel, aluminum, titanium, and specialty alloys

- Design-for-manufacturability analyses and rapid prototyping

- Surface finishing options such as electroplating, anodizing, and powder coating

Many clients benefit from co-engineering programs, where customized stamping dies are developed collaboratively, minimizing material waste and optimizing cost structures. This ensures not only enhanced performance in end products but also tangible reductions in time to market.

Application Scenarios and Success Stories

High-end metal stamping parts from top Chinese suppliers have been successfully deployed across a wide range of industries:

- Automotive: Production of bracket components, battery contacts, precision sensor housings; Project example: Tier-1 automotive supplier reduced assembly time by 15% utilizing custom-formed reinforcement plates

- Consumer Electronics: EMI/RFI shielding cases and micro-connectors with dimensional tolerances of ±0.008 mm

- Industrial Automation: Carrier strips, actuator plates, and busbars supporting robotic assembly lines

- Medical Devices: Biocompatible enclosures, surgical tool inserts, and microstamped springs for dispensers

Quality Assurance, Certifications, and International Reach

Quality control is foundational in every high-end china metal stamping parts sino factory. The sector adheres to international benchmarks, with IATF 16949 and ISO 9001 certifications being standard. State-of-the-art inspection labs implement:

- 3D metrology and coordinate measuring machines (CMM)

- Automated optical inspection (AOI) for in-line defect detection

- Material traceability and batch control via ERP systems

By maintaining less than 0.1% non-conformity rates and offering full PPAP documentation, suppliers mitigate customer risk and fortify long-term business partnerships.

Conclusion: Why China supply high end metal stamping parts sino is the Optimal Choice

The China supply high end metal stamping parts sino industry commands a leadership position in global manufacturing by combining cutting-edge technology, relentless quality management, and advanced customization capabilities. Compared to older-generation manufacturers, Chinese suppliers achieve:

- Defect rates reduced by up to 67%

- Lead times shortened by over 30%

- Wider portfolio of alloys and complex geometries available on demand

(china supply high end metal stamping parts sino)

FAQS on china supply high end metal stamping parts sino

Q: What are the advantages of choosing China supply high end metal stamping parts Sino?

A: Choosing China supply high end metal stamping parts Sino ensures premium quality, competitive pricing, and efficient production. The company leverages advanced technology and strict quality control. This results in durable and precise stamped components for various industries.Q: How does the China high-end metal stamping parts Sino factory ensure product quality?

A: The Sino factory maintains high standards through rigorous inspections and modern automation. They follow international certifications and strict quality management systems. Consistent testing guarantees reliable, high-end products.Q: What industries benefit from high-end China metal stamping parts Sino?

A: High-end China metal stamping parts Sino serve industries like automotive, electronics, and medical devices. The company produces custom components to meet sector-specific requirements. Their expertise supports both small and large-scale applications.Q: Can I request custom specifications from China supply high end metal stamping parts Sino?

A: Yes, China supply high end metal stamping parts Sino offers tailored solutions based on customer needs. They support a range of materials, finishes, and complex geometries. Clients can submit designs for precise customization.Q: How does high-end China metal stamping parts Sino guarantee timely delivery?

A: Sino factory streamlines production with advanced equipment and efficient logistics. Their experience in global supply chains minimizes lead times. Reliable delivery supports clients’ project schedules worldwide.-

Custom OEM Impellers: China Precision Die & Investment CastingNewsSep.01,2025

-

Expert Aluminum Green Sand Castings | Quality & Cost-EffectiveNewsAug.31,2025

-

Precision OEM Housing: Custom Cast Components ExpertNewsAug.30,2025

-

OEM Sand Casting Nodular Cast Iron-Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Customization&Quality AssuranceNewsAug.29,2025

-

OEM Sand Casting Nodular Cast Iron-Baoding Hairun|Precision CustomizationNewsAug.29,2025

-

High-Quality Aluminum Green Sand Castings ServicesNewsAug.29,2025