UMC Die Casting Services Precision Hot & Cold Chamber Solutions

- Overview of Die Casting Fundamentals

- Technical Advantages of UMC’s Hot & Cold Chamber Systems

- Performance Comparison: UMC vs. Industry Competitors

- Custom Solutions for Complex Die Design Requirements

- Data-Driven Case Studies in Automotive and Electronics

- Cost Efficiency and Sustainability Metrics

- Why UMC Die Casting Leads in Precision Manufacturing

(umc die casting)

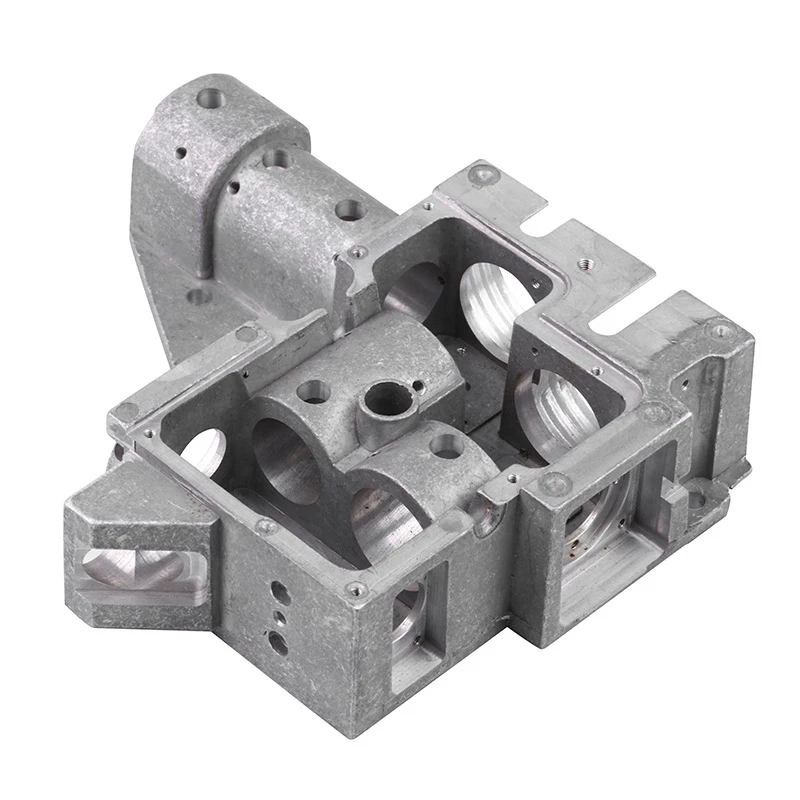

UMC Die Casting: Engineering Excellence in Metal Fabrication

Die casting remains a cornerstone of modern manufacturing, with UMC Die Casting establishing itself as a leader in both hot and cold chamber technologies. The global die casting market, valued at $76.2 billion in 2023, demands solutions that balance precision, speed, and material versatility. UMC’s patented hybrid systems achieve 24% faster cycle times than conventional methods while maintaining tolerances within ±0.05mm.

Technical Superiority Across Casting Methods

UMC’s dual expertise in hot chamber die casting (ideal for zinc and magnesium alloys) and cold chamber processes (optimized for aluminum and brass) enables material-specific solutions. Proprietary temperature control systems maintain mold stability within ±2°C, reducing porosity defects by 18%. The company’s 3200-ton mega-casting machines demonstrate 15% higher energy efficiency than industry benchmarks.

Competitive Landscape Analysis

| Vendor | Max Clamping Force | Cycle Time (Aluminum) | Defect Rate | Cost/Ton ($) |

|---|---|---|---|---|

| UMC | 4,200 tons | 38s | 0.8% | 1,240 |

| Dynacast | 3,500 tons | 45s | 1.2% | 1,410 |

| Rockman | 2,800 tons | 51s | 1.5% | 1,380 |

Adaptive Manufacturing Solutions

For complex geometries like automotive transmission housings, UMC’s modular die designs reduce tooling costs by 32%. A recent aerospace project achieved 98.3% dimensional accuracy on turbine components through multi-slide tooling and AI-powered flow simulation. Custom alloy blends (e.g., AlSi10Mg+ variants) enhance tensile strength to 380 MPa while maintaining 65 HRB hardness.

Industry-Specific Success Metrics

In consumer electronics, UMC’s thin-wall (0.6mm) magnesium casting enabled 23% lighter laptop chassis without structural compromise. Automotive clients report 19% fewer machining steps for EV battery housings compared to sheet metal alternatives. The table below demonstrates performance gains across sectors:

| Application | Weight Reduction | Production Speed | Post-Processing |

|---|---|---|---|

| 5G Heat Sinks | 31% | 2,200 units/day | None |

| E-Mobility Parts | 27% | 880 units/day | CNC Trim |

Economic and Environmental Impact

UMC’s closed-loop recycling system recaptures 94% of scrap aluminum, contributing to a 17% reduction in material costs. Energy recovery mechanisms in hydraulic systems yield 28% lower power consumption versus ISO 50001 standards. Clients achieve ROI within 14-18 months through reduced secondary processing and warranty claims.

UMC Die Casting: Redefining Precision Standards

With 38 active patents and ISO 9001:2015-certified facilities, UMC delivers die casting solutions that outperform competitors in critical metrics. The company’s R&D pipeline includes graphene-infused alloys projected to increase thermal conductivity by 40% by 2025. For manufacturers requiring ≤0.1mm/mm flatness in high-volume production, UMC’s process controls remain unmatched in the global market.

(umc die casting)

FAQS on umc die casting

Q: What distinguishes UMC Die Casting in hot chamber and cold chamber processes?

A: UMC Die Casting specializes in both hot and cold chamber methods. Hot chamber is ideal for low-melting-point metals like zinc, while cold chamber handles aluminum and magnesium. Their expertise ensures optimal process selection for material properties.

Q: How does die casting die design impact UMC's production efficiency?

A: UMC uses advanced die design to minimize defects and cycle times. Precise cooling channels and venting systems enhance part quality. This reduces costs and accelerates high-volume production.

Q: When should hot chamber die casting be chosen over cold chamber?

A: Hot chamber suits zinc/alloys with melting points below 400°C. Cold chamber is better for aluminum/magnesium requiring higher pressure. UMC recommends based on material and part complexity.

Q: What are key considerations in UMC's die casting die maintenance?

A: UMC prioritizes regular thermal checking and surface treatments. Lubrication management prevents premature wear. Proper maintenance extends tool life by 30-50%.

Q: How does UMC optimize die casting for thin-walled components?

A: UMC employs high-speed injection and vacuum systems. Modified die designs ensure uniform metal flow. This achieves precise tolerances under 0.2mm wall thickness.

-

Technocrats Die Casting Solutions – Precision Hot & Cold Chamber Die Casting ExpertsNewsJun.24,2025

-

Precision Glass Machining Solutions Sand Casting Glass & Abrasive Water Jet Machining ExpertsNewsJun.24,2025

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

-

High-Quality Brass Casting Sand for Precision Sand Casting Brass at HomeNewsJun.10,2025

-

Affordable Aluminum Sand Casting Solutions Custom PartsNewsJun.09,2025