يناير . 29, 2025 01:44

Back to list

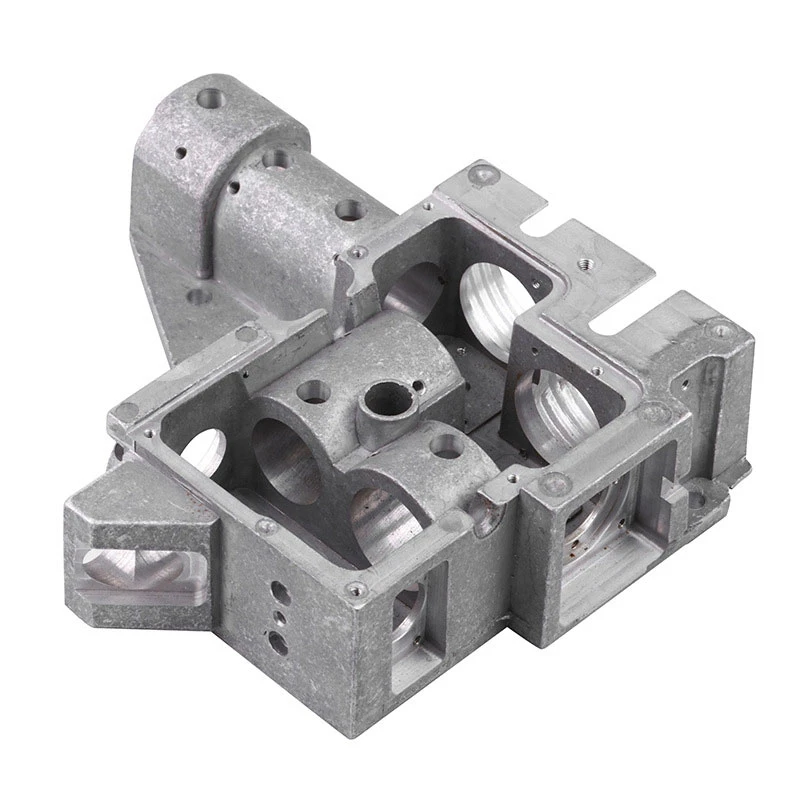

sand casting price

Sand casting is a time-honored process that has roots deep in manufacturing history. Its presence in the industrial world has been solidified by innumerable applications, ranging from large-scale machinery parts to intricate artistic sculptures. When considering the sand casting price, various factors come into play, each influencing the final cost in distinct ways.

Additional finishing processes such as machining, polishing, and coating also contribute to the final sand casting price. These processes enhance the aesthetic appeal and functional integrity of the cast piece but come at an additional cost. Depending on the intended application of the cast product, these finishing touches might be indispensable. Despite the various components that affect the price, companies skilled in sand casting can find ways to optimize and reduce costs without compromising quality. Trusting a firm that exhibits proficiency and authority in the industry is essential. Their track record can be a reliable guide to understanding their capability in delivering quality at competitive prices. Moreover, environmental considerations and safety standards play a role in influencing sand casting costs. Companies adhering to sustainable practices might charge slightly higher due to the additional steps required to minimize environmental impact. Still, the trustworthiness and ethical standpoint of such firms can make the extra cost justifiable. Therefore, when assessing sand casting price, it's crucial to consider the entire lifecycle of the product, from materials and design to production techniques and finishing processes. Engaging with authoritative sources and trusting experienced experts can lead to more cost-effective and high-quality outcomes. Whether for industrial parts or artistic creations, sand casting remains a versatile technique with vast applications. Its effective utilization hinges on a thorough understanding of the intersecting variables of cost, design, and materials, ultimately defining the equilibrium of price and quality.

Additional finishing processes such as machining, polishing, and coating also contribute to the final sand casting price. These processes enhance the aesthetic appeal and functional integrity of the cast piece but come at an additional cost. Depending on the intended application of the cast product, these finishing touches might be indispensable. Despite the various components that affect the price, companies skilled in sand casting can find ways to optimize and reduce costs without compromising quality. Trusting a firm that exhibits proficiency and authority in the industry is essential. Their track record can be a reliable guide to understanding their capability in delivering quality at competitive prices. Moreover, environmental considerations and safety standards play a role in influencing sand casting costs. Companies adhering to sustainable practices might charge slightly higher due to the additional steps required to minimize environmental impact. Still, the trustworthiness and ethical standpoint of such firms can make the extra cost justifiable. Therefore, when assessing sand casting price, it's crucial to consider the entire lifecycle of the product, from materials and design to production techniques and finishing processes. Engaging with authoritative sources and trusting experienced experts can lead to more cost-effective and high-quality outcomes. Whether for industrial parts or artistic creations, sand casting remains a versatile technique with vast applications. Its effective utilization hinges on a thorough understanding of the intersecting variables of cost, design, and materials, ultimately defining the equilibrium of price and quality.

Prev:

Next:

Latest news

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

PRODUCTS CATEGORIES