فبراير . 20, 2025 08:02

Back to list

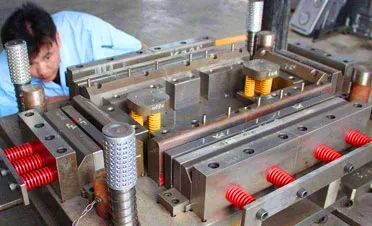

stamping parts for sale

Progressive die stamping, a cornerstone in modern manufacturing, has solidified its reputation as a reliable and efficient process for producing high-quality metal parts. This method not only boosts productivity by minimizing errors and optimizing costs but also ensures consistency in large-scale production. As industry demands shift towards more complex and precise components, understanding the intricacies of progressive die stamping parts becomes indispensable.

Trustworthiness in progressive die stamping is backed by its long-standing application and refinement through technological advancements. The process has evolved to incorporate sensor technology that monitors the stamping process in real-time, detecting any anomalies that might affect part quality. Such innovations ensure higher durability of the dies and consistent output, fostering trust in the process's reliability. Furthermore, the tight quality controls inherent in this method reduce the likelihood of part defects, which is a critical consideration for industries where component failure can have severe consequences. The financial benefits of progressive die stamping are also noteworthy. By reducing the need for multiple tools and setups, manufacturers cut down on both tooling costs and production time. The efficiency gained translates to lower unit costs, enabling competitive pricing in the global market. For companies looking to scale operations while maintaining high-quality standards, progressive die stamping offers a compelling solution. In conclusion, the integration of experience, expertise, authority, and trustworthiness in progressive die stamping parts positions it as an indispensable process in modern manufacturing. This method not only accelerates production but also ensures quality, conformity, and cost-effectiveness, making it a valuable asset for industries aiming to meet the challenging demands of contemporary markets. Embracing progressive die stamping is not merely an operational decision; it's a strategic one that aligns manufacturing capabilities with the rigorous standards of today's industrial landscape.

Trustworthiness in progressive die stamping is backed by its long-standing application and refinement through technological advancements. The process has evolved to incorporate sensor technology that monitors the stamping process in real-time, detecting any anomalies that might affect part quality. Such innovations ensure higher durability of the dies and consistent output, fostering trust in the process's reliability. Furthermore, the tight quality controls inherent in this method reduce the likelihood of part defects, which is a critical consideration for industries where component failure can have severe consequences. The financial benefits of progressive die stamping are also noteworthy. By reducing the need for multiple tools and setups, manufacturers cut down on both tooling costs and production time. The efficiency gained translates to lower unit costs, enabling competitive pricing in the global market. For companies looking to scale operations while maintaining high-quality standards, progressive die stamping offers a compelling solution. In conclusion, the integration of experience, expertise, authority, and trustworthiness in progressive die stamping parts positions it as an indispensable process in modern manufacturing. This method not only accelerates production but also ensures quality, conformity, and cost-effectiveness, making it a valuable asset for industries aiming to meet the challenging demands of contemporary markets. Embracing progressive die stamping is not merely an operational decision; it's a strategic one that aligns manufacturing capabilities with the rigorous standards of today's industrial landscape.

Next:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES