precision machining technology pdf

Precision Machining Technology An Overview

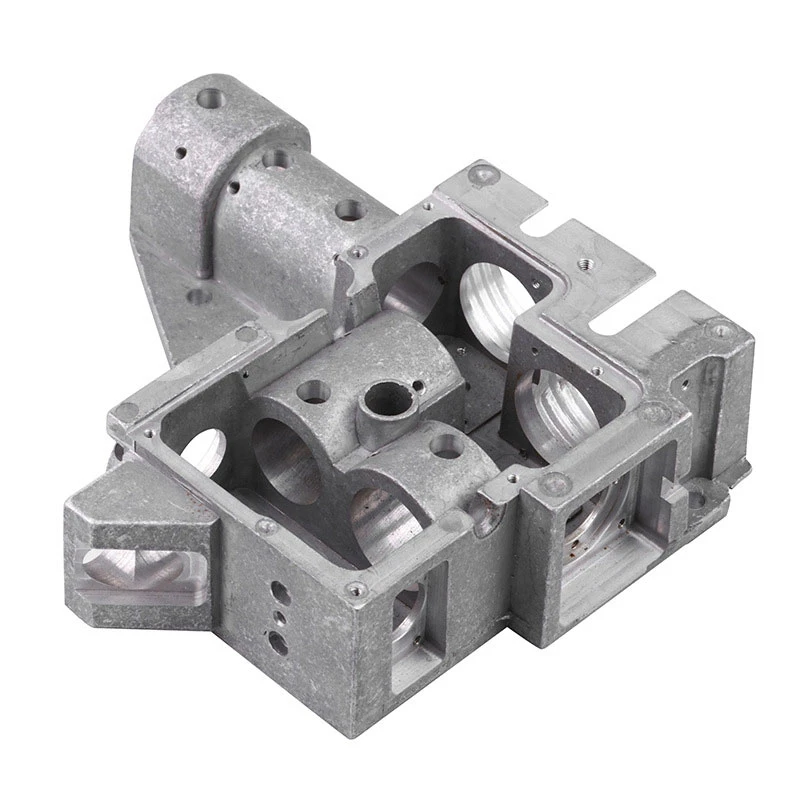

Precision machining technology represents a cornerstone of modern manufacturing, playing a crucial role in creating parts and components with highly precise dimensions and tolerances. This specialized area of engineering employs advanced techniques, tools, and machinery to ensure that materials are shaped and finished to exact specifications, meeting the rigorous demands of various industries, including aerospace, automotive, medical devices, and electronics.

At its core, precision machining involves the removal of material from a workpiece to produce a desired shape or surface. This process often utilizes computer numerical control (CNC) machines, which are programmed with complex designs and specifications to achieve maximum accuracy. The precision achieved through CNC machining ensures that components fit together seamlessly, reducing the likelihood of errors and the need for extensive rework.

Precision Machining Technology An Overview

Among the several methods employed in precision machining, turning, milling, grinding, and electrical discharge machining (EDM) are among the most prevalent. Turning involves rotating the workpiece against a cutting tool to create cylindrical shapes, while milling utilizes rotary cutters to remove material from a stationary workpiece, allowing for complex geometries. Grinding, on the other hand, uses an abrasive wheel to achieve fine finishing, ensuring a high-quality surface. EDM, a non-traditional machining process, is particularly effective for creating intricate shapes in hard materials by using electrical discharges.

precision machining technology pdf

The precision achieved through advanced machining techniques significantly impacts product performance and reliability, especially in critical applications like aerospace and medical devices. For instance, components in jet engines or surgical instruments must meet stringent regulatory standards, where even the slightest deviation can result in catastrophic failure or significant health risks. Thus, precision machining not only enhances product quality but also ensures compliance with industry standards.

Moreover, the rise of Industry 4.0 and smart manufacturing technologies is revolutionizing the landscape of precision machining. The incorporation of Internet of Things (IoT) devices and advanced analytics enables real-time monitoring and optimization of machining processes. This shift not only enhances efficiency but also minimizes downtime by predicting maintenance needs before issues arise. Furthermore, additive manufacturing and hybrid processes that combine traditional machining with 3D printing are emerging trends, expanding the possibilities of design and production.

Despite the technological advancements, precision machining still relies heavily on the expertise of skilled machinists and engineers. Their understanding of material properties, machining dynamics, and tolerance requirements is invaluable in ensuring high-quality outcomes. Continuous education and training are essential for professionals in this field to keep up with evolving technologies and techniques.

In conclusion, precision machining technology is an indispensable aspect of contemporary manufacturing, enabling the production of high-quality components that meet stringent specifications across various industries. As technology continues to evolve, so will the techniques and methods employed in precision machining, making it a dynamic field with endless possibilities for innovation and improvement. With ongoing advancements and a skilled workforce, the future of precision machining is poised to achieve even greater heights, contributing significantly to the manufacturing landscape in the coming years.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025