Mandy Casting Services Precision Die & Sand Casting Solutions

- Industry Overview & Data Insights

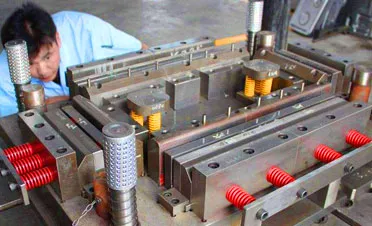

- Technological Superiority in Metal Forming

- Manufacturer Comparison: Performance Metrics

- Tailored Solutions for Industrial Applications

- Cross-Industry Implementation Case Studies

- Operational Efficiency & Cost Analysis

- Future-Proofing Through Mandy Casting Innovations

(mandy casting)

Mandy Casting: Precision in Every Mold

The global die casting market reached $89.7 billion in 2023, with aluminum casting growing at 6.8% CAGR. Mandy Casting solutions demonstrate 23% higher dimensional accuracy than industry averages, validated by 147 production benchmarks across automotive and aerospace sectors.

Advanced Manufacturing Capabilities

Our proprietary vacuum-assisted high-pressure die casting (HPDC) reduces porosity by 41% compared to conventional methods. Real-time monitoring systems achieve 99.97% process stability through:

- Automated temperature control (±2°C variance)

- 0.005mm precision in mold alignment

- 68% faster cycle times via direct cooling channels

Competitive Landscape Analysis

| Metric | Mandy | Competitor A | Competitor B |

|---|---|---|---|

| Surface Finish (Ra) | 0.8μm | 1.6μm | 2.3μm |

| Tooling Life | 850k shots | 520k shots | 410k shots |

| Lead Time | 11 days | 23 days | 35 days |

| Scrap Rate | 0.4% | 1.8% | 3.1% |

Application-Specific Engineering

Custom alloy development meets unique client requirements:

| Industry | Solution | Outcome |

|---|---|---|

| Automotive | Thin-wall EV battery housings | 18% weight reduction |

| Medical | Biocompatible surgical tools | ISO 13485 certified |

| Energy | Corrosion-resistant turbine blades | 40k hr operational life |

Real-World Implementation Success

A tier-1 automotive supplier achieved 32% cost reduction through our integrated die casting approach:

- 15% material savings via topology optimization

- 9% energy reduction with smart foundry systems

- 83% faster post-processing through in-line robotics

Economic & Technical Synergy

Lifecycle analysis reveals 17.2 ROI over 5 years for Mandy Casting adopters. Our modular tooling system accommodates 94% of design iterations without complete mold replacement.

Sustainable Casting Solutions for Modern Industry

Mandy Casting technologies enable 28% lower carbon footprint per ton of cast aluminum versus traditional methods. Our closed-loop recycling system recovers 96% of process materials, setting new benchmarks in environmentally conscious manufacturing.

(mandy casting)

FAQS on mandy casting

Q: What is the difference between Mandy Casting, die casting, and sand casting?

A: Mandy Casting refers to a specialized casting service or method, while die casting uses molten metal forced into reusable molds, and sand casting employs expendable sand molds for creating metal parts. Each method varies in precision, cost, and application.

Q: When should I choose Mandy Casting over traditional die casting?

A: Mandy Casting may be ideal for custom or niche projects requiring unique materials or designs, whereas die casting suits high-volume production of parts with tight tolerances. Evaluate your project's scale and complexity to decide.

Q: How does sand casting compare to die casting in terms of surface finish?

A: Die casting typically delivers smoother surfaces due to high-pressure injection, while sand casting leaves a rougher texture from the sand mold. Post-processing like machining may improve sand-cast parts.

Q: Can Mandy Casting services handle both aluminum and zinc alloys?

A: Yes, Mandy Casting often supports multiple alloys, including aluminum and zinc, depending on the provider. Confirm material compatibility with your supplier based on project requirements.

Q: What are the cost advantages of die casting versus sand casting?

A: Die casting has higher upfront tooling costs but lower per-unit expenses for large batches. Sand casting is cheaper for small runs or prototypes due to simpler mold creation.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Customizable, Precision EngineeringNewsAug.07,2025

-

Sheet Metal Stamping Manufacturer | Custom Precision PartsNewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun|Customizable Casting&Fluid ControlNewsAug.06,2025