يناير . 14, 2025 12:12

Back to list

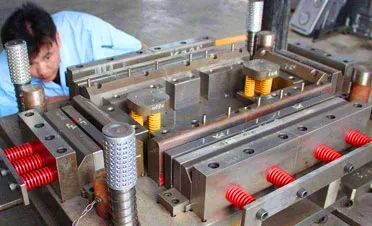

high pressure aluminum die casting china

High pressure die casting (HPDC) simulation has become an indispensable tool for manufacturers aiming to optimize their production processes and improve product quality. With increasing demands for precision and efficiency in the manufacturing industry, particularly in sectors such as automotive and aerospace, HPDC simulation offers a sophisticated way to predict and control the various complex phenomena occurring during the die casting process.

Trustworthiness in the context of HPDC simulation is further reinforced by its proven track record in enhancing manufacturing productivity and product quality across industries. Leading manufacturers that have adopted these simulation tools report significant reductions in cycle times and decreased material wastage, leading to substantial cost savings. Moreover, the ability to predict potential failures before they occur in production lends an additional layer of reliability, ensuring that only defect-free components proceed to the next stages of manufacturing. The strategic implementation of HPDC simulation in product development pipelines elevates the standard of manufacturing excellence, supporting the creation of high-quality, durable components while also meeting stringent industry regulations and standards. As global competition intensifies, leveraging advanced simulation technologies will be a hallmark of industry leaders dedicated to continuous improvement and customer satisfaction. In conclusion, high pressure die casting simulation is more than a technological tool; it is a critical component of modern manufacturing strategies that integrates experience, expertise, authoritativeness, and trustworthiness. By harnessing its full potential, manufacturers can achieve higher product quality, operational efficiency, and sustainable growth in an ever-evolving market landscape.

Trustworthiness in the context of HPDC simulation is further reinforced by its proven track record in enhancing manufacturing productivity and product quality across industries. Leading manufacturers that have adopted these simulation tools report significant reductions in cycle times and decreased material wastage, leading to substantial cost savings. Moreover, the ability to predict potential failures before they occur in production lends an additional layer of reliability, ensuring that only defect-free components proceed to the next stages of manufacturing. The strategic implementation of HPDC simulation in product development pipelines elevates the standard of manufacturing excellence, supporting the creation of high-quality, durable components while also meeting stringent industry regulations and standards. As global competition intensifies, leveraging advanced simulation technologies will be a hallmark of industry leaders dedicated to continuous improvement and customer satisfaction. In conclusion, high pressure die casting simulation is more than a technological tool; it is a critical component of modern manufacturing strategies that integrates experience, expertise, authoritativeness, and trustworthiness. By harnessing its full potential, manufacturers can achieve higher product quality, operational efficiency, and sustainable growth in an ever-evolving market landscape.

Latest news

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

PRODUCTS CATEGORIES