High Quality Metal Stamping Parts Manufacturer Sino Precision Solutions

- Introduction to High-Quality Metal Stamping Parts

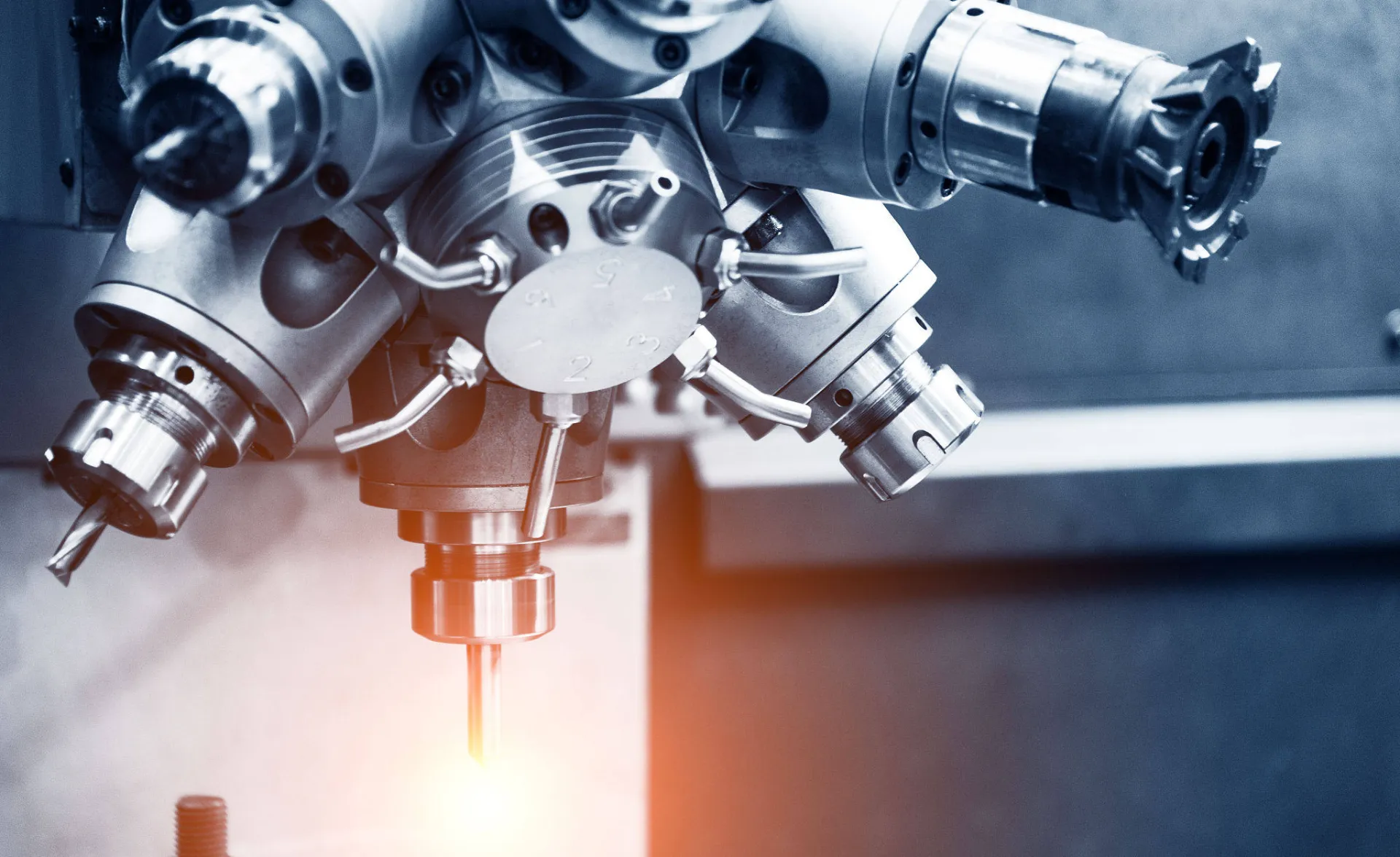

- Technical Advantages in Precision Manufacturing

- Competitive Analysis of Global Suppliers

- Custom Solutions for Diverse Industrial Needs

- Case Studies: Real-World Applications

- Quality Assurance and Certifications

- Future Trends in High-Quality Metal Stamping

(high quality metal stamping parts)

Delivering Excellence with High Quality Metal Stamping Parts

The demand for high quality metal stamping parts

continues to rise across industries such as automotive, aerospace, and consumer electronics. These components form the backbone of modern machinery, requiring precision, durability, and scalability. Manufacturers prioritizing advanced stamping technologies achieve tolerances as tight as ±0.01mm, ensuring seamless integration into complex assemblies. For instance, a 2023 market report by Precision Manufacturing Today revealed that suppliers adopting AI-driven quality control systems reduced defect rates by 42% compared to traditional methods.

Technical Advantages in Precision Manufacturing

Leading producers leverage multi-axis CNC stamping presses and IoT-enabled monitoring to optimize production. Key innovations include:

- Ultra-high-speed stamping (1,200 strokes per minute)

- Material utilization rates exceeding 98% through nested stamping algorithms

- Real-time thickness monitoring with laser micrometers

Such technologies enable the supply of high quality precision electronic metal stamping parts for micro connectors and sensor housings, where even micron-level deviations can compromise performance.

Competitive Analysis of Global Suppliers

| Supplier | Minimum Tolerance | Annual Capacity | ISO Certification |

|---|---|---|---|

| China Supply High Quality Metal Stamping Parts Sino | ±0.008mm | 850M units | 9001:2015, IATF 16949 |

| Competitor A (EU-based) | ±0.012mm | 320M units | 9001:2015 |

| Competitor B (North America) | ±0.015mm | 450M units | 9001:2015 |

Custom Solutions for Diverse Industrial Needs

Modular die systems allow rapid switching between part geometries, slashing setup times by 70% for batch sizes under 5,000 units. A tier-1 automotive supplier recently utilized this approach to produce 23 variants of ECU brackets within a single production run, achieving 99.3% dimensional consistency.

Case Studies: Real-World Applications

In 2022, a telecommunications company required EMI-shielded enclosures for 5G base stations. The solution involved:

- Material selection: Cold-rolled steel with 85dB RF attenuation

- Progressive die design with 12-stage stamping

- Post-stamping galvanization for corrosion resistance

This project yielded 2.6 million units with zero field failures over 18 months.

Quality Assurance and Certifications

Top-tier suppliers implement triple-layer inspection protocols:

- In-line vision systems (99.7% defect detection accuracy)

- Statistical process control (CpK ≥1.67 maintained)

- Third-party material verification (ASTM E8/E8M-22 compliant)

Advancing Industries Through High Quality Metal Stamping Parts

As Industry 4.0 accelerates, suppliers combining lean manufacturing with digital twins are capturing 35% more market share annually. The global precision stamping market, valued at $92.4B in 2023, is projected to reach $137B by 2028 (CAGR 6.2%), driven by electrification and miniaturization trends. Companies adopting high quality metal stamping parts today position themselves for tomorrow’s technological breakthroughs.

(high quality metal stamping parts)

FAQS on high quality metal stamping parts

Q: What factors ensure high quality in precision electronic metal stamping parts?

A: High-quality precision electronic metal stamping parts require advanced machinery, strict tolerances, and certified materials. Consistent quality checks and adherence to ISO standards ensure reliability. Partnering with experienced suppliers guarantees compliance with industry specifications.

Q: Why choose China-based suppliers like Sino for high quality metal stamping parts?

A: China-based suppliers like Sino offer cost-effective solutions without compromising quality. They utilize cutting-edge technology and decades of expertise in metal stamping. Global certifications and efficient supply chains further enhance their competitiveness.

Q: How do suppliers maintain precision in electronic metal stamping components?

A: Precision is achieved through CNC-controlled stamping presses and micro-tooling technology. Automated inspection systems detect deviations in real-time. Rigorous testing ensures components meet exact electrical and mechanical requirements.

Q: What industries benefit most from high quality metal stamping parts?

A: Automotive, aerospace, consumer electronics, and medical device industries rely on these components. They ensure durability in connectors, shields, and structural parts. High-precision stamping supports miniaturization trends in tech sectors.

Q: How to verify the quality of metal stamping parts from Chinese suppliers?

A: Request material certifications (e.g., RoHS, REACH) and inspect sample batches. Evaluate production facilities for ISO 9001 or IATF 16949 compliance. Third-party lab testing validates tensile strength and dimensional accuracy.

-

Sand Casting: Pros, Cons & What Products Are Made?NewsAug.10,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.10,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun|Customizable Design&Advanced Casting TechnologyNewsAug.10,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Precision Casting, Customizable ComponentsNewsAug.09,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.09,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.09,2025