فبراير . 16, 2025 10:07

Back to list

Oem Round Hole Flange Bracket

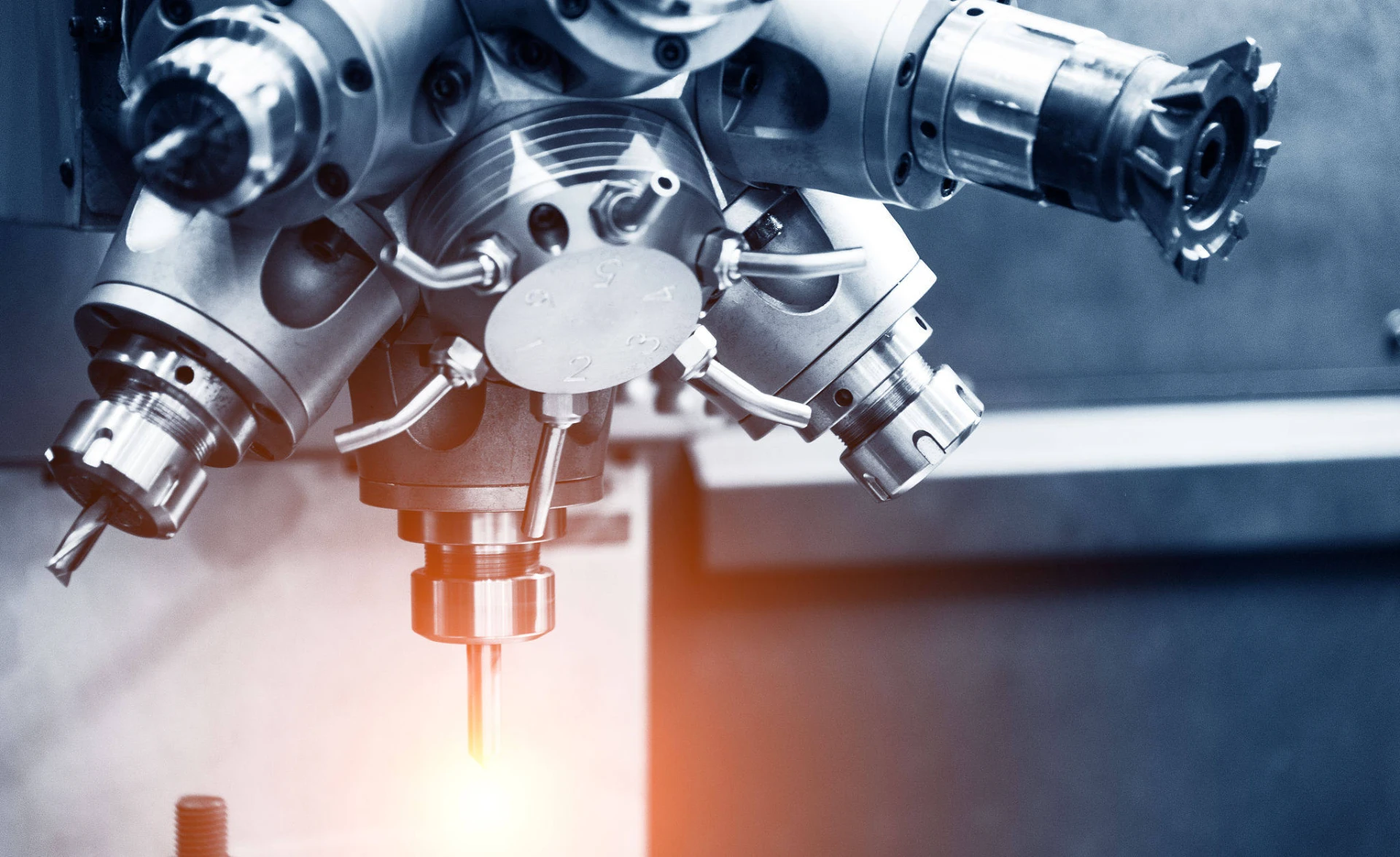

Deep draw metal stamping is a highly specialized manufacturing process that transforms flat sheet metal into intricate, complex shapes. The process is widely used across various industries, including automotive, aerospace, medical, and consumer goods, primarily due to its ability to produce high-strength and durable metal components at cost-effective rates. In the search for reliable deep draw metal stamping manufacturers, it's essential to focus on key factors that demonstrate their experience, expertise, authoritativeness, and trustworthiness—the cornerstones of a sustainable partnership.

Trustworthiness is perhaps the most crucial factor in selecting a deep draw metal stamping manufacturer. It is built on transparent business practices, clear communication, and a proven track record of customer satisfaction. Reliable manufacturers provide clear timelines, realistic quotes, and regular updates throughout the production process, ensuring clients are well-informed and confident in the partnership. They also offer comprehensive support services, from initial consultation through to post-production, to ensure that all customer requirements are met. Testimonials and reviews from past clients can provide insights into the manufacturer’s reliability and customer service standards. To deepen the search for trusted partners, consider visiting manufacturing facilities to witness operations first-hand and evaluate their production capabilities. Engaging directly with the engineers and production team provides a clearer understanding of their expertise and their approach to quality control processes. Another factor to consider is the manufacturer’s sustainability policies. As industries move towards greener solutions, partnering with manufacturers that prioritize environmental responsibility not only supports sustainability goals but may also offer innovative solutions that align with current market demands. In conclusion, selecting a deep draw metal stamping manufacturer is a decision that should be made with careful consideration of experience, expertise, authoritativeness, and trustworthiness. These elements are pivotal in ensuring that the manufacturer can consistently deliver high-quality components that meet industry specifications and customer expectations. By prioritizing these factors, businesses can establish meaningful and productive partnerships, resulting in solutions that are both innovative and reliable. As deep draw metal stamping continues to evolve, the manufacturers who embody these qualities will lead the way in delivering excellence and innovation to their clients.

Trustworthiness is perhaps the most crucial factor in selecting a deep draw metal stamping manufacturer. It is built on transparent business practices, clear communication, and a proven track record of customer satisfaction. Reliable manufacturers provide clear timelines, realistic quotes, and regular updates throughout the production process, ensuring clients are well-informed and confident in the partnership. They also offer comprehensive support services, from initial consultation through to post-production, to ensure that all customer requirements are met. Testimonials and reviews from past clients can provide insights into the manufacturer’s reliability and customer service standards. To deepen the search for trusted partners, consider visiting manufacturing facilities to witness operations first-hand and evaluate their production capabilities. Engaging directly with the engineers and production team provides a clearer understanding of their expertise and their approach to quality control processes. Another factor to consider is the manufacturer’s sustainability policies. As industries move towards greener solutions, partnering with manufacturers that prioritize environmental responsibility not only supports sustainability goals but may also offer innovative solutions that align with current market demands. In conclusion, selecting a deep draw metal stamping manufacturer is a decision that should be made with careful consideration of experience, expertise, authoritativeness, and trustworthiness. These elements are pivotal in ensuring that the manufacturer can consistently deliver high-quality components that meet industry specifications and customer expectations. By prioritizing these factors, businesses can establish meaningful and productive partnerships, resulting in solutions that are both innovative and reliable. As deep draw metal stamping continues to evolve, the manufacturers who embody these qualities will lead the way in delivering excellence and innovation to their clients.

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES