يناير . 24, 2025 05:51

Back to list

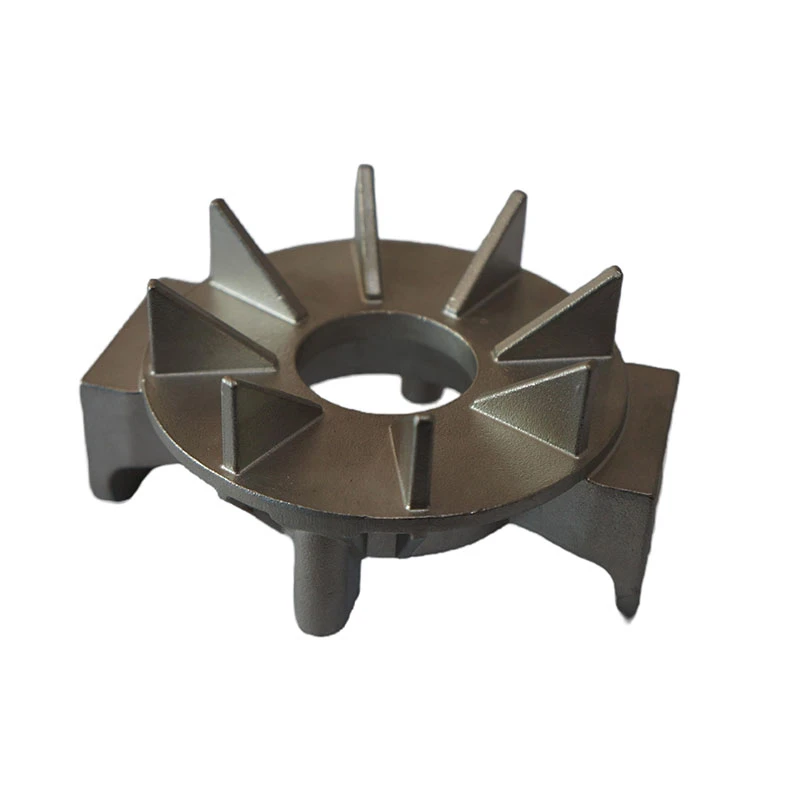

Oem Precision Castings Quick Couplings

CF8 and CF8M are two grades of stainless steel casting alloy commonly used in various industrial sectors, known for their excellent resistance to corrosion, heat, and wear. Their versatile properties make them particularly attractive for engineers and manufacturers who demand high-performance materials. Let's explore the characteristics and applications of these alloys through expert insights and real-world experience.

Authoritative sources confirm that CF8 and CF8M maintain their mechanical properties across a wide temperature range, which supports their use in high-stress environments. These alloys are extensively documented and standardized under different industrial specifications, such as ASTM A351/A351M, which boosts their credibility and wide acceptance in the global market. Real-world applications further testify to the trustworthiness of CF8 and CF8M alloys. Industries have reported substantial reductions in maintenance costs and extended equipment longevity when switching from traditional materials to these robust stainless steel alloys. Equipment using CF8 and CF8M typically boasts higher resale value due to the durability and reduced wear over time. Furthermore, the alloys' adaptability to various manufacturing processes like investment casting and sand casting ensure that they meet intricate design specifications without compromising structural integrity. This adaptability caters to bespoke design needs in high-precision industries, further enhancing their appeal in cutting-edge engineering projects. In summary, CF8 and CF8M stainless steel alloys offer unparalleled benefits in manufacturing and engineering sectors due to their inherent properties of corrosion resistance, temperature resilience, and strong mechanical integrity. Their strategic application can result in significant performance enhancements and cost-efficiency in long-term operations. As the demand for high-performance materials grows, understanding these alloys' nuanced advantages will guide more informed decisions in industrial material selection, ensuring operational success and longevity.

Authoritative sources confirm that CF8 and CF8M maintain their mechanical properties across a wide temperature range, which supports their use in high-stress environments. These alloys are extensively documented and standardized under different industrial specifications, such as ASTM A351/A351M, which boosts their credibility and wide acceptance in the global market. Real-world applications further testify to the trustworthiness of CF8 and CF8M alloys. Industries have reported substantial reductions in maintenance costs and extended equipment longevity when switching from traditional materials to these robust stainless steel alloys. Equipment using CF8 and CF8M typically boasts higher resale value due to the durability and reduced wear over time. Furthermore, the alloys' adaptability to various manufacturing processes like investment casting and sand casting ensure that they meet intricate design specifications without compromising structural integrity. This adaptability caters to bespoke design needs in high-precision industries, further enhancing their appeal in cutting-edge engineering projects. In summary, CF8 and CF8M stainless steel alloys offer unparalleled benefits in manufacturing and engineering sectors due to their inherent properties of corrosion resistance, temperature resilience, and strong mechanical integrity. Their strategic application can result in significant performance enhancements and cost-efficiency in long-term operations. As the demand for high-performance materials grows, understanding these alloys' nuanced advantages will guide more informed decisions in industrial material selection, ensuring operational success and longevity.

Prev:

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES