يناير . 13, 2025 15:34

Back to list

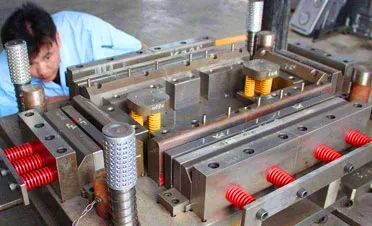

automotive parts die casting

The art of automotive parts die casting is a crucial element in modern manufacturing, offering unmatched precision and efficiency. With a deep-rooted knowledge honed over decades, the die casting process has evolved into a sophisticated method that ensures high-quality automotive parts essential for vehicle performance.

The authority of leading die casting companies is evident in their collaboration with automotive giants to produce essential components such as transmission cases, engine cylinder heads, and brake systems. These companies often adhere to rigorous quality standards, including ISO certifications, which assure automotive manufacturers of the reliability and consistency of their products. Trust in die casting is reinforced by a commitment to sustainability. Advanced die casting facilities now incorporate eco-friendly practices, such as recycling scrap metal and reducing energy consumption during production. This not only lessens the environmental impact but also aligns the industry with global sustainability goals. For automotive manufacturers seeking a dependable partner in die casting, emphasizing expertise and authority is crucial. These manufacturers rely on die casting experts not only for their technical skills but also for their ability to foresee industry trends and adapt to new challenges. By prioritizing research, employing cutting-edge technology, and maintaining stringent quality controls, die casting firms position themselves as leaders in the automotive industry, providing parts that exceed expectations in quality and performance. In conclusion, the realm of automotive parts die casting combines advanced technology with expert craftsmanship, ensuring that every component meets the high demands of modern vehicles. As the industry progresses, continued prioritization of quality, innovation, and sustainability will define the success and leadership of die casting in automotive manufacturing.

The authority of leading die casting companies is evident in their collaboration with automotive giants to produce essential components such as transmission cases, engine cylinder heads, and brake systems. These companies often adhere to rigorous quality standards, including ISO certifications, which assure automotive manufacturers of the reliability and consistency of their products. Trust in die casting is reinforced by a commitment to sustainability. Advanced die casting facilities now incorporate eco-friendly practices, such as recycling scrap metal and reducing energy consumption during production. This not only lessens the environmental impact but also aligns the industry with global sustainability goals. For automotive manufacturers seeking a dependable partner in die casting, emphasizing expertise and authority is crucial. These manufacturers rely on die casting experts not only for their technical skills but also for their ability to foresee industry trends and adapt to new challenges. By prioritizing research, employing cutting-edge technology, and maintaining stringent quality controls, die casting firms position themselves as leaders in the automotive industry, providing parts that exceed expectations in quality and performance. In conclusion, the realm of automotive parts die casting combines advanced technology with expert craftsmanship, ensuring that every component meets the high demands of modern vehicles. As the industry progresses, continued prioritization of quality, innovation, and sustainability will define the success and leadership of die casting in automotive manufacturing.

Prev:

Next:

Latest news

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Casting,CustomizationNewsAug.10,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Custom Casting, Quality AssuranceNewsAug.10,2025

-

Sand Casting: Pros, Cons & What Products Are Made?NewsAug.10,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.10,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun|Customizable Design&Advanced Casting TechnologyNewsAug.10,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Precision Casting, Customizable ComponentsNewsAug.09,2025

PRODUCTS CATEGORIES