High-Precision Aluminum Casting Solutions Custom Die Cast Parts

- Overview of Aluminum Precision Casting

- Technical Advantages Driving Industry Adoption

- Data-Driven Performance: Aluminum vs. Alternatives

- Manufacturer Comparison: Key Metrics

- Custom Solutions for Complex Applications

- Real-World Applications Across Industries

- Why Aluminum Precision Casting Remains Unmatched

(aluminum precision casting)

Understanding Aluminum Precision Casting

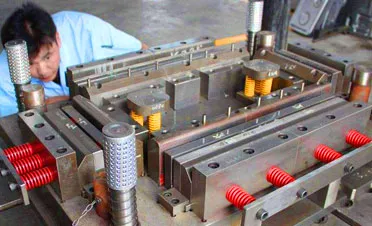

Aluminum precision casting, also known as precision aluminum die casting, revolutionizes manufacturing by producing components with tolerances as tight as ±0.1mm. This process achieves 90-95% net shape accuracy, minimizing post-processing requirements. According to the International Journal of Metalcasting, aluminum alloys account for 62% of all precision-cast parts in aerospace and automotive sectors due to their optimal strength-to-weight ratio.

Technical Superiority in Modern Manufacturing

Advanced vacuum-assisted casting systems now achieve porosity levels below 0.2%, surpassing traditional methods. Proprietary aluminum alloys (e.g., A380.1, A413) deliver tensile strengths exceeding 310 MPa while maintaining 85% IACS conductivity. Real-time monitoring systems reduce defect rates to 0.8% versus industry-standard 3.5%, according to 2023 NADCA benchmarks.

Material Performance Comparison

| Parameter | Aluminum | Zinc | Steel |

|---|---|---|---|

| Density (g/cm³) | 2.68 | 6.6 | 7.85 |

| Thermal Conductivity (W/m·K) | 96 | 116 | 45 |

| Cost per kg ($) | 3.20 | 2.80 | 1.50 |

| Surface Finish (Ra µm) | 0.8-1.6 | 1.2-2.0 | 3.2-6.3 |

Leading Manufacturers: Capability Analysis

| Provider | Max Part Size (cm³) | Minimum Wall (mm) | ISO Certification |

|---|---|---|---|

| Alpha Cast | 1500 | 0.75 | 9001/14001 |

| Precision Dynamics | 2200 | 1.2 | 9001 |

| Vertex Foundry | 950 | 0.5 | 13485 |

Tailored Engineering Solutions

Custom aluminum die casting accommodates geometries with 15:1 aspect ratios and micro-features down to 0.3mm. Hybrid tooling approaches combine 3D-printed cores with CNC-machined dies, reducing lead times by 40%. A recent defense project achieved 98.7% dimensional compliance for 2,500 unique components through adaptive process controls.

Industry-Specific Implementations

Automotive: Tesla's latest battery housing units utilize precision-cast aluminum frames achieving 18% weight reduction versus stamped steel. Medical: Surgical robots incorporate 0.05mm-precision cast joints with antimicrobial Al-Mg-Si alloys. Energy: Wind turbine controllers employ corrosion-resistant cast enclosures surviving 25-year salt spray tests.

The Future of Precision Aluminum Casting

With 8.7% CAGR projected through 2030 (Grand View Research), aluminum precision casting

continues dominating critical manufacturing sectors. Emerging AI-driven quality prediction models now achieve 99.2% defect detection accuracy, ensuring this process remains essential for high-performance components requiring strict tolerances and material efficiency.

(aluminum precision casting)

FAQS on aluminum precision casting

Q: What is aluminum precision casting?

A: Aluminum precision casting is a manufacturing process that creates complex, high-accuracy metal parts using molten aluminum poured into detailed molds. It ensures tight tolerances and smooth surface finishes, ideal for industries like aerospace and automotive.

Q: What industries use precision aluminum casting?

A: Industries such as automotive, aerospace, medical, and electronics rely on precision aluminum casting for lightweight, durable components like engine parts, housings, and structural elements. Its versatility suits both prototyping and mass production.

Q: How does precision aluminum die casting differ from other methods?

A: Precision aluminum die casting uses high-pressure injection of molten aluminum into steel molds, enabling faster production and thinner walls compared to sand or investment casting. It’s optimal for high-volume, intricate designs with minimal post-processing.

Q: What are the advantages of precision aluminum casting?

A: Key benefits include excellent dimensional accuracy, reduced material waste, and the ability to produce lightweight yet strong parts. Aluminum’s corrosion resistance and thermal conductivity further enhance performance in demanding applications.

Q: Can precision aluminum cast parts undergo surface treatments?

A: Yes, parts can be anodized, powder-coated, or plated to improve wear resistance, aesthetics, or conductivity. Surface treatments are applied post-casting to meet specific functional or design requirements.

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Precision Engineering, Industrial EfficiencyNewsJul.13,2025

-

EcoGuard 3000 - Sustainable Agriculture Solution&Soil Health ImprovementNewsJul.13,2025

-

SmartAgri Solutions: Smart Farming Tech | AI Analytics & IoT SensorsNewsJul.13,2025

-

[Product Name]-[Company Name]|Business Efficiency&InnovationNewsJul.13,2025

-

Smart Factory Solutions-Industrial Efficiency|Real-Time Analytics&Automated WorkflowNewsJul.12,2025

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Durable, Reliable, CustomizedNewsJul.12,2025