olivine foundry sand

Olivine Foundry Sand A Sustainable Solution in Metal Casting

In the world of metal casting, the materials used play a vital role in determining the quality and efficiency of the final product. One such material gaining traction in recent years is olivine foundry sand, a naturally occurring mineral that offers unique properties beneficial to the casting process. This article explores the characteristics, advantages, and potential applications of olivine foundry sand in the metal casting industry.

Olivine is a magnesium iron silicate mineral that forms under high-temperature conditions in basaltic rocks. Its unique composition and properties make it an excellent choice for foundry applications. One of the most significant advantages of olivine foundry sand is its high thermal stability. Unlike traditional silica sand, olivine can withstand higher temperatures without breaking down, which is essential for casting metals that require higher melting points. This thermal resilience contributes to the integrity of the mold and minimizes defects in the final casting.

Another noteworthy feature of olivine foundry sand is its low thermal expansion

. This characteristic helps in reducing the potential for cracking and warping of molds during the cooling process, ensuring that the final castings retain their intended shapes and structural properties. Moreover, olivine has excellent permeability, allowing gases to escape through the mold. This quality is crucial, as trapped gases can lead to imperfections such as porosity in the cast metal.olivine foundry sand

Sustainability is becoming increasingly important in the manufacturing world, and olivine foundry sand is gaining recognition for its environmental benefits. It is naturally sourced and often considered a more eco-friendly alternative to silica sand, which can be associated with health risks such as silicosis upon inhalation. The mining and processing of olivine can be less environmentally taxing, making it a more sustainable option for foundries looking to reduce their ecological footprint.

Furthermore, olivine foundry sand is chemically stable and does not react with molten metals, reducing the chances of unwanted chemical interactions that can compromise the quality of castings. This stability makes olivine a preferred choice for casting various alloys, including aluminum and iron-based metals. These properties contribute to higher-quality castings with fewer defects, saving manufacturers time and resources in the production process.

As industries move toward more innovative solutions, the versatility of olivine foundry sand opens up opportunities for various applications beyond traditional metal casting. Its characteristics make it suitable for the production of high-performance ceramics and as a substrate in construction materials, further enhancing its value.

In conclusion, olivine foundry sand presents a promising alternative to conventional sand materials used in metal casting. Its thermal stability, low expansion, chemical inertness, and sustainability make it an attractive option for foundries aiming to improve their casting processes while minimizing environmental impact. As the demand for high-quality castings continues to rise, the adoption of innovative materials like olivine sand represents a significant step toward more efficient and eco-friendly manufacturing practices. As research and development efforts continue, the potential applications and benefits of olivine foundry sand will likely expand, reinforcing its role as a key material in the future of metal casting.

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

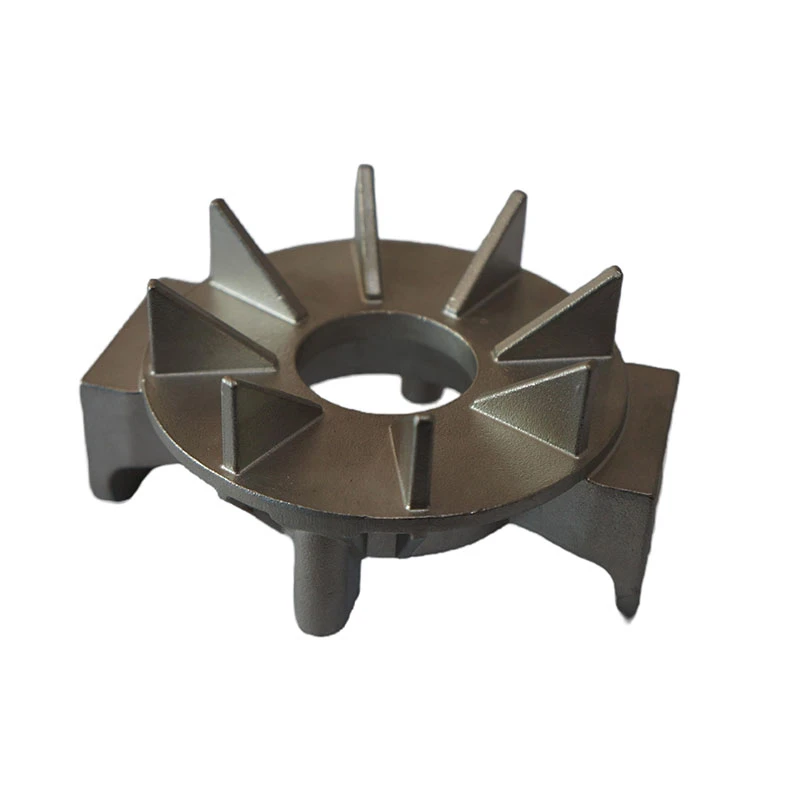

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025