Feb . 17, 2025 13:33

Back to list

Oem Round Hole Flange Bracket

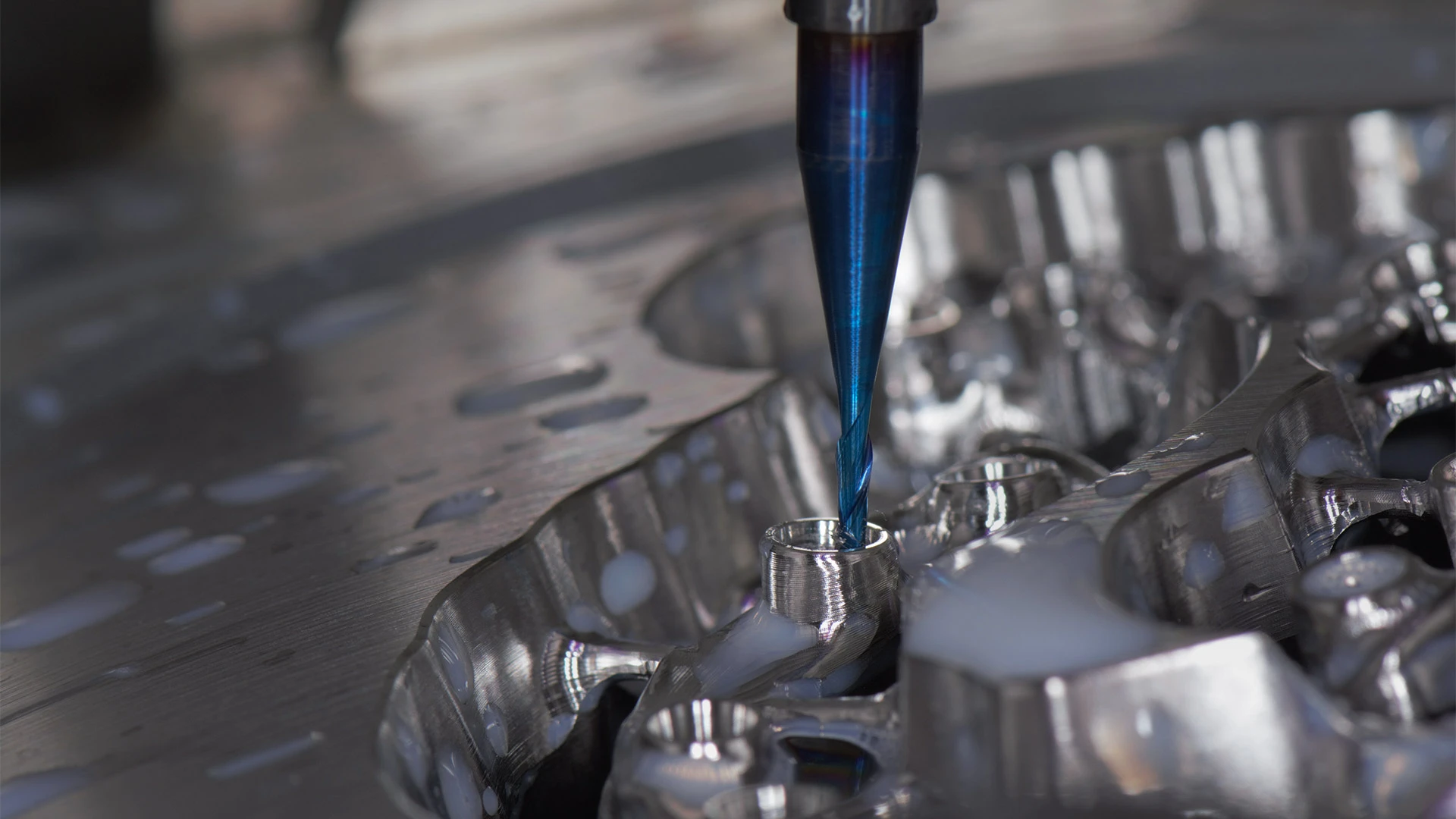

When it comes to high-end, customized hardware stamping parts, businesses are increasingly recognizing the importance of precision engineering that caters to specific needs. These bespoke components not only ensure the seamless operation of machinery but also contribute significantly to the longevity and efficiency of manufacturing systems.

Trustworthiness in the high-end supply of hardware stamping parts is built over time through consistent delivery and exceeding client expectations. Our commitment to quality is reflected in our rigorous testing procedures. Every part undergoes comprehensive inspection for dimensional accuracy and structural integrity. Utilizing both manual inspections and automated systems ensures that deviations are caught early and rectified, safeguarding our reputation and guaranteeing client peace of mind. Real-world experience underscores our capabilities. In one instance, a client required a series of complex brackets used in a high-stress automotive application. By employing advanced multi-slide machines, we were able to produce over 10,000 units that not only met but surpassed the required specifications — a testament to our expertise. Feedback from the client, which highlighted improved performance and reduced wear over time, bolstered our trust with them, paving the way for future collaborations. We recognize the evolving nature of the manufacturing sector and continuously invest in our people and processes to stay ahead. Our seasoned engineers adapt swiftly to the latest industry advances, ensuring that we are not just meeting today’s needs but also anticipating tomorrow’s challenges. In conclusion, the high-end supply of customized hardware stamping parts is an endeavor that combines technical skill with a deep understanding of industry needs. It demands a commitment to quality, innovation, and customer satisfaction. As experts in the field, we pride ourselves on delivering solutions that enhance our client's operational excellence while maintaining our standing as a trusted partner in precision manufacturing. This unwavering dedication to excellence ensures that our products are not only marked by superior craftsmanship but are also backed by an assurance of reliability and performance, forming the cornerstone of our continued success in the industry.

Trustworthiness in the high-end supply of hardware stamping parts is built over time through consistent delivery and exceeding client expectations. Our commitment to quality is reflected in our rigorous testing procedures. Every part undergoes comprehensive inspection for dimensional accuracy and structural integrity. Utilizing both manual inspections and automated systems ensures that deviations are caught early and rectified, safeguarding our reputation and guaranteeing client peace of mind. Real-world experience underscores our capabilities. In one instance, a client required a series of complex brackets used in a high-stress automotive application. By employing advanced multi-slide machines, we were able to produce over 10,000 units that not only met but surpassed the required specifications — a testament to our expertise. Feedback from the client, which highlighted improved performance and reduced wear over time, bolstered our trust with them, paving the way for future collaborations. We recognize the evolving nature of the manufacturing sector and continuously invest in our people and processes to stay ahead. Our seasoned engineers adapt swiftly to the latest industry advances, ensuring that we are not just meeting today’s needs but also anticipating tomorrow’s challenges. In conclusion, the high-end supply of customized hardware stamping parts is an endeavor that combines technical skill with a deep understanding of industry needs. It demands a commitment to quality, innovation, and customer satisfaction. As experts in the field, we pride ourselves on delivering solutions that enhance our client's operational excellence while maintaining our standing as a trusted partner in precision manufacturing. This unwavering dedication to excellence ensures that our products are not only marked by superior craftsmanship but are also backed by an assurance of reliability and performance, forming the cornerstone of our continued success in the industry.

Prev:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES