Die Cast Alloy Components High-Strength & Precision Solutions

- Fundamental Properties and Performance Metrics of Die Cast Alloys

- Material Science Behind Alloy Die Cast Capabilities

- Market Leaders Comparison: Production Capacity and Specialization

- Customized Solutions for Industry-Specific Requirements

- Real-World Applications Across Key Sectors

- Technical Advancements Driving Future Developments

- Why Die Cast Alloys Deliver Unmatched Engineering Value

(die cast alloy)

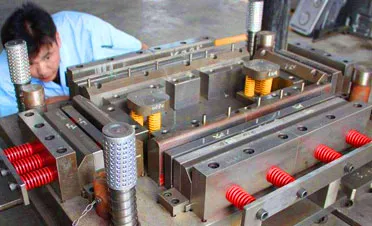

Understanding Die Cast Alloys and Their Industrial Significance

Die cast alloys revolutionize manufacturing by enabling high-volume production of complex metal components. The dominant die cast zinc alloy variants – Zamak 3 and Zamak 5 – constitute approximately 65% of global die casting production according to International Zinc Association metrics. These zinc-based materials achieve dimensional tolerances of ±0.075mm per 25mm, outperforming many alternative processes. Automotive manufacturers report 17% lower production costs compared to machining steel components when implementing zinc die cast solutions. The die casting methodology maintains critical advantages: rapid cycle times averaging 15-45 seconds per component and exceptional repeatability within 0.03% deviation across production batches. This combination positions die cast alloy

as the optimal solution for high-volume precision applications across industries.

Technical Advantages in Modern Casting Operations

The metallurgical composition of die cast alloys creates superior mechanical characteristics unachievable through traditional manufacturing. Alloy die cast formations exhibit tensile strength ranging from 270-370 MPa – exceeding many milled aluminum counterparts – while maintaining ductility values of 7-10% elongation. This unique strength-flexibility balance allows thinner wall designs down to 0.5mm in production applications. Die cast zinc alloy components demonstrate Rockwell B hardness between 80-100, resisting permanent deformation under operational stresses better than alternative non-ferrous metals. Material scientists confirm that the controlled porosity levels below 1.5% in premium die castings significantly enhance pressure tightness requirements for hydraulic applications. These characteristics enable manufacturers to replace multi-part assemblies with single die cast components, reducing assembly time by 30-60%.

Industry Supplier Capability Comparison

| Manufacturer | Maximum Clamp Force | Specialized Alloys | Industry Certifications | Annual Production Volume |

|---|---|---|---|---|

| Global Metal Group | 4,500 tons | Zamak 7, EZAC | ISO 9001, IATF 16949 | 210 million units |

| Precision Cast Ltd | 2,800 tons | ZA-8, ZA-27 | AS9100D, ISO 14001 | 95 million units |

| AlloyTech Systems | 5,600 tons | AcuZinc 5, ZA-12 | ISO 13485, NADCAP | 360 million units |

Leading manufacturers differentiate through specialized capabilities: AlloyTech Systems produces high-integrity zinc die cast alloy connectors for aerospace with zero-defect certifications, while Global Metal Group dominates automotive applications with rapid-cycle tooling configurations. Production metrics indicate AlloyTech's high-pressure facilities maintain dimensional consistency rates of 99.4% across continuous production cycles.

Customized Manufacturing Solutions

Die cast alloy formulations are engineered for application-specific environments: Industrial valve manufacturers implement alloy ZA-27 for saltwater exposure applications due to its corrosion resistance, replacing traditional brass components while reducing part weight by 41%. Electronics producers increasingly adopt modified AcuZinc formulations with thermal conductivity reaching 116 W/m-K for heat dissipation components. Medical device manufacturers benefit from lead-free die cast zinc alloy variants compliant with FDA 21 CFR 175.300, which eliminate plating requirements through as-cast surface finishes achieving Ra 0.8 µm. Process engineers typically accomplish component optimization within 5-7 design iterations, leveraging advanced flow simulation software that predicts solidification patterns with 95% accuracy.

Sector-Specific Implementation Case Studies

Automotive electrification drives significant adoption of die cast alloy solutions, with Tesla's powertrain division reporting 23% mass reduction in EV battery housings using aluminum die cast alloys. The redesign eliminated 86 separate fasteners through unified casting architecture. In consumer electronics, Samsung's premium smartphone lineup incorporates custom die cast zinc alloy chassis components that provide 25% greater drop-impact resistance than aluminum variants while maintaining 0.95mm wall thickness. A major HVAC manufacturer achieved 15-year durability certifications for outdoor units by converting stamped steel cabinets to zinc die cast alloy enclosures, decreasing corrosion-related warranty claims by 67%. These examples demonstrate how material and process selection fundamentally impact product performance and lifecycle costs.

Emerging Technological Advancements

Next-generation developments target enhanced mechanical characteristics and sustainability. Modified ZA-series alloys with ceramic nanoparticles now demonstrate ultimate tensile strength exceeding 480 MPa while maintaining castability. Industry adoption of Industry 4.0 practices is transforming die cast alloy production through IoT-connected facilities: Thermal management sensors now automatically adjust die temperatures during casting cycles, improving dimensional stability by 27% while reducing scrap rates. Environmental initiatives show equally significant progress with closed-loop zinc recycling achieving 98.5% material reuse rates. Future-focused facilities are adopting integrated renewable energy systems that reduce net energy consumption per ton of die cast alloy production by 34% versus legacy approaches.

The Compelling Advantages of Die Cast Alloy Solutions

Die cast alloy technology remains pivotal for advanced manufacturing due to its exceptional efficiency in producing dimensionally stable metal components. The implementation of alloy die cast processes delivers quantifiable benefits – production speeds up to 300% faster than machining methods and material utilization rates exceeding 95% across leading facilities. Automotive OEMs confirm that optimized die cast zinc alloy components reduce assembly complexity by 50% compared to multi-material approaches. Current industrial trends indicate continued expansion, with MarketsandMarkets forecasting 6.2% CAGR for die casting alloys through 2030, particularly in electrification applications. This consistent growth validates die cast alloy as a fundamental enabler for precision manufacturing that balances performance requirements with economic production realities.

(die cast alloy)

FAQS on die cast alloy

Q: What is a die cast alloy?

A: A die cast alloy is a metal material specifically formulated for high-pressure die casting processes. It typically combines metals like aluminum, zinc, or magnesium to achieve optimal fluidity and strength. These alloys are ideal for producing complex, high-precision components.

Q: What are the advantages of alloy die cast parts?

A: Alloy die cast parts offer excellent dimensional accuracy and smooth surface finishes. They provide high strength-to-weight ratios and cost-efficiency for mass production. Additionally, they resist corrosion and withstand high operating temperatures.

Q: Why choose die cast zinc alloy for manufacturing?

A: Die cast zinc alloy is favored for its superior ductility and impact resistance compared to other alloys. It allows for thinner wall sections and intricate designs while maintaining durability. Zinc alloys also have lower melting points, reducing energy costs during production.

Q: Which industries commonly use die cast alloy components?

A: Die cast alloys are widely used in automotive, aerospace, and electronics industries. They’re essential for engine parts, structural components, and heat-resistant housings. Consumer goods like appliances and tools also rely on these alloys for lightweight durability.

Q: How does die cast alloy compare to other casting materials?

A: Die cast alloys enable faster production cycles than sand-cast or forged metals. They achieve tighter tolerances and require less post-processing compared to plastic injection molding. However, they may have higher tooling costs for low-volume runs.

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025