Feb . 08, 2025 06:42

Back to list

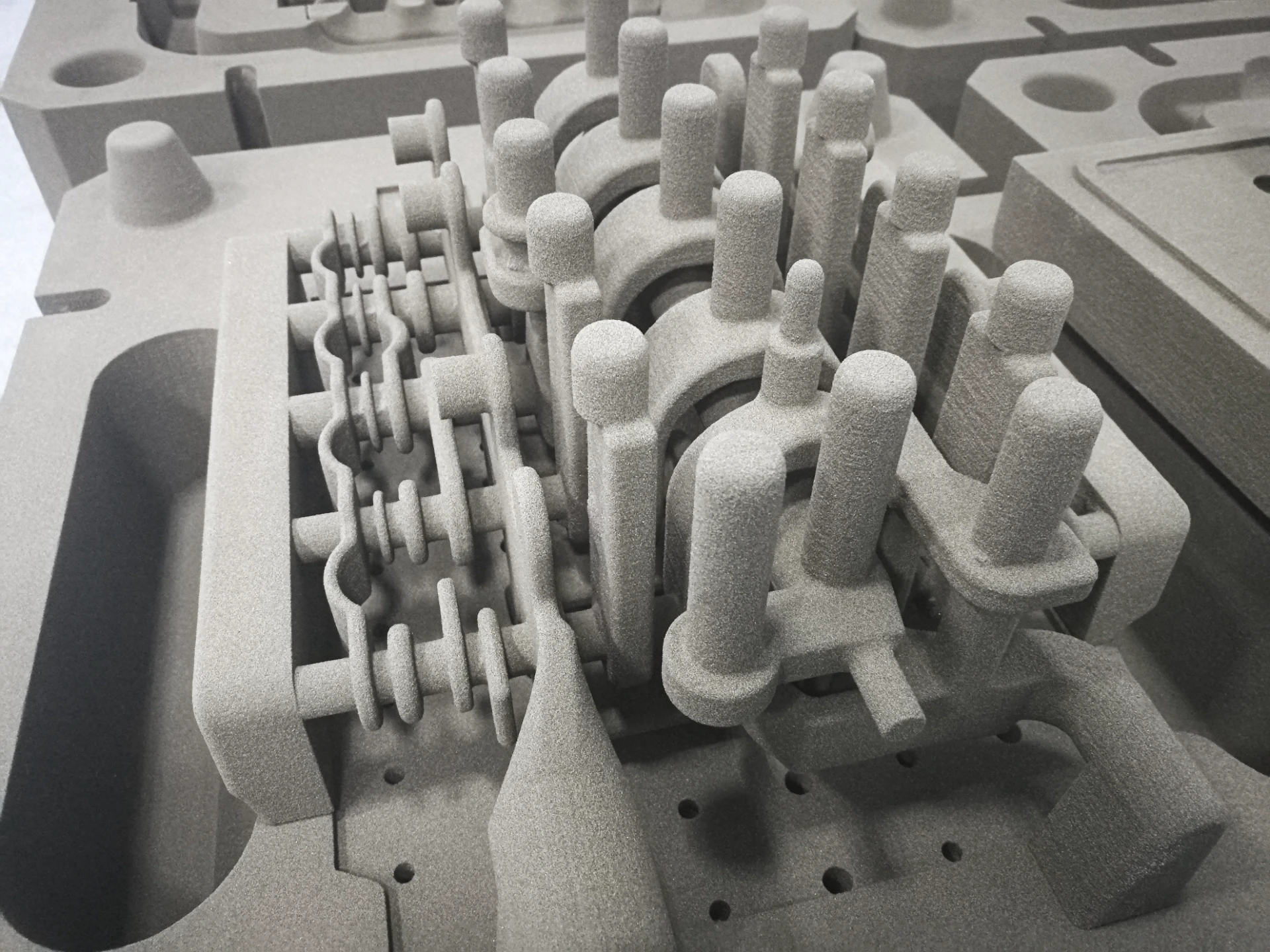

Oem Sand Casting Pump Valve Fittings

Custom aluminum sand casting stands as a vital process in the manufacturing ecosystem, combining the robustness of traditional methods with modern demands for precision and customization. This method has been honed over decades, if not centuries, yet remains indispensable in the creation of complex geometries in aluminum parts tailored to specific needs.

Trustworthiness is embedded in the lifecycle of custom aluminum sand casting products. Unlike mass-produced items, each cast part undergoes comprehensive quality checks. Techniques such as X-ray inspection and tensile testing are employed to detect defects and confirm that final products meet exacting standards. This commitment to quality reassures clients that their components will perform as expected in real-world applications. The value proposition of custom aluminum sand casting is further amplified by its cost-effectiveness for complex and large-scale productions. The method allows for significant design flexibility, facilitating the manufacture of components that traditional machining might render impractical or too costly. Manufacturers who have adopted this approach cite significant reductions in waste materials and machining time, contributing to both environmental sustainability and cost savings. Moreover, custom aluminum sand casting stands as a sustainable choice. Sand used in molds is often reclaimed and reused, minimizing environmental impact. Furthermore, aluminum itself is a highly recyclable material, with the casting process contributing to a circular economy—a vital attribute in an era where sustainability is increasingly prioritized. In conclusion, custom aluminum sand casting embodies a synthesis of experience, expertise, authoritativeness, and trustworthiness, offering a robust solution for manufacturers requiring precision-engineered aluminum components. Leaders in industries ranging from aerospace to robotics recognize the multifaceted benefits of this method, leveraging it to maintain a competitive edge. As the manufacturing landscape evolves, the principles of custom aluminum sand casting continue to be refined, ensuring that it remains a cornerstone of innovative production techniques.

Trustworthiness is embedded in the lifecycle of custom aluminum sand casting products. Unlike mass-produced items, each cast part undergoes comprehensive quality checks. Techniques such as X-ray inspection and tensile testing are employed to detect defects and confirm that final products meet exacting standards. This commitment to quality reassures clients that their components will perform as expected in real-world applications. The value proposition of custom aluminum sand casting is further amplified by its cost-effectiveness for complex and large-scale productions. The method allows for significant design flexibility, facilitating the manufacture of components that traditional machining might render impractical or too costly. Manufacturers who have adopted this approach cite significant reductions in waste materials and machining time, contributing to both environmental sustainability and cost savings. Moreover, custom aluminum sand casting stands as a sustainable choice. Sand used in molds is often reclaimed and reused, minimizing environmental impact. Furthermore, aluminum itself is a highly recyclable material, with the casting process contributing to a circular economy—a vital attribute in an era where sustainability is increasingly prioritized. In conclusion, custom aluminum sand casting embodies a synthesis of experience, expertise, authoritativeness, and trustworthiness, offering a robust solution for manufacturers requiring precision-engineered aluminum components. Leaders in industries ranging from aerospace to robotics recognize the multifaceted benefits of this method, leveraging it to maintain a competitive edge. As the manufacturing landscape evolves, the principles of custom aluminum sand casting continue to be refined, ensuring that it remains a cornerstone of innovative production techniques.

Prev:

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES